A method for improving the efficiency of macroalgae anaerobic fermentation

A technology of anaerobic fermentation and macroalgae, applied in microorganism-based methods, fermentation, biochemical equipment and methods, etc., can solve problems such as restricting production efficiency and economic benefits, unfavorable uniform dispersion, and low lipid content, and achieves H2S Mitigation of toxic effects, avoidance of severe acidification, reduction of VFA accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Collect macroalgae Macrocystis pyrifera, air-dry and grind to make the particle size less than or equal to 2mm, and measure its TS and VS to be 90.42% and 61.77%, respectively.

[0028] (2) The anaerobic fermentation biogas slurry of straw was used as the inoculum, and its TS and VS were measured to be 2.73% and 72.06%, respectively.

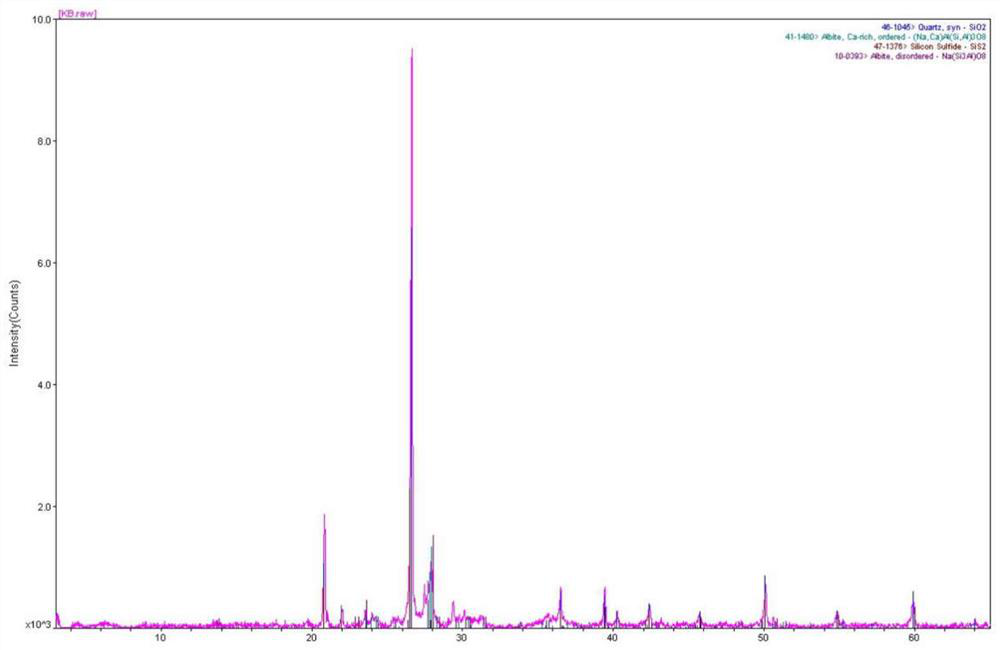

[0029] (3) Take 20g of ceramsite, soak it in distilled water, wash it, and dry it in an oven at 55°C. Take 5g of ceramsite and grind it, carry out X-ray diffraction test, and obtain the schematic diagram of ceramsite composition as shown in figure 1 shown.

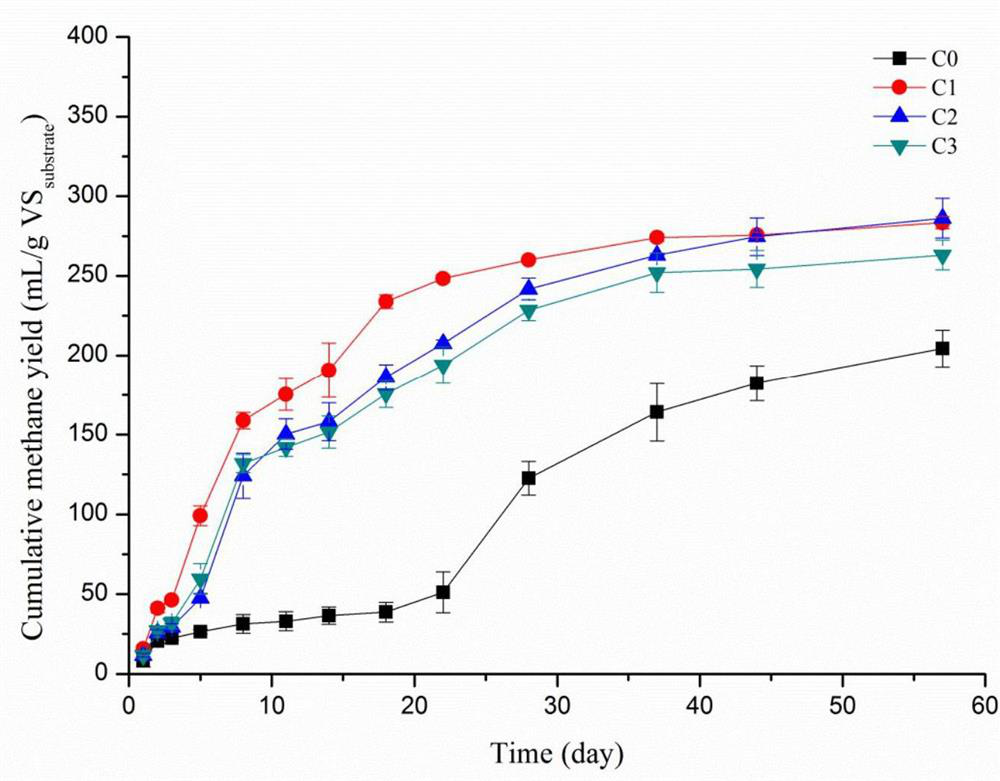

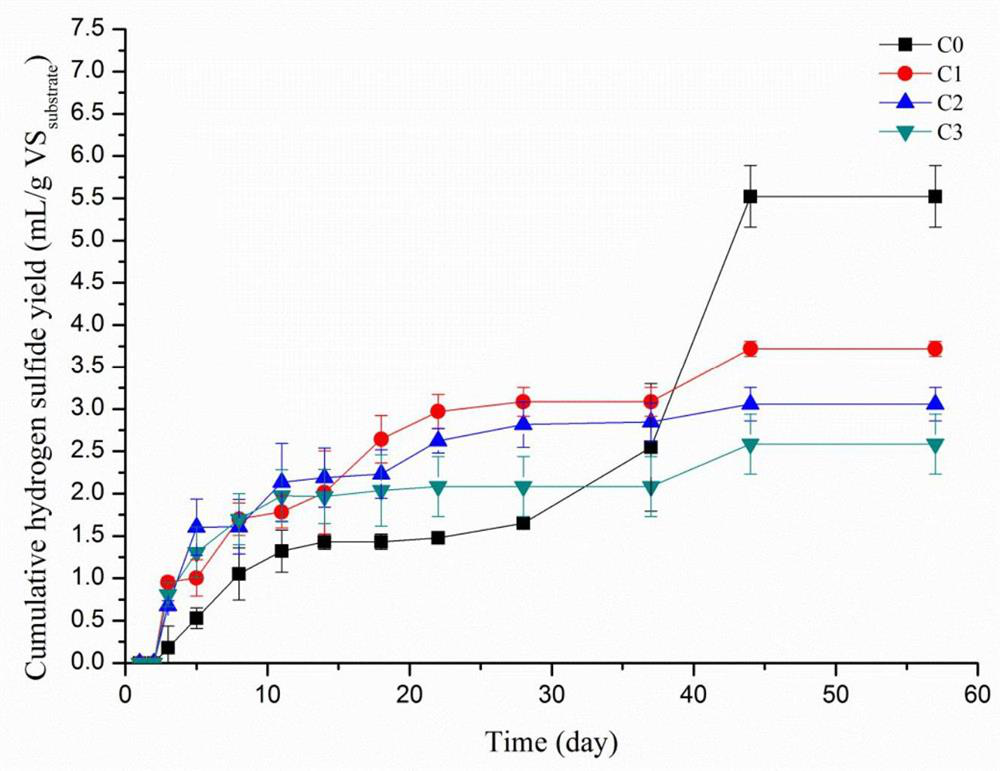

[0030] (4) Take 12 shake flasks of 250 mL, wash them, and dry them in an oven at 55°C. Add 3 g of macroalgae as a substrate in the above step (1) and 45.83 mL of the biogas slurry in the above step (2) as an inoculum to each of them. Among them, 3 were not added with ceramsite, which was the C0 group (control group); each of the 3 were added with 4.5g (1.5g / g substrate ) cerams...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com