Method for preparing humic acid-containing water-soluble fertilizer from alcohol biogas slurry

A technology of humic acid and biogas slurry, applied in liquid fertilizers, nitrate fertilizers, ammonium orthophosphate fertilizers, etc., can solve problems such as pollution, and achieve the effects of regulating plant growth, improving utilization rate, and enriching nutrients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

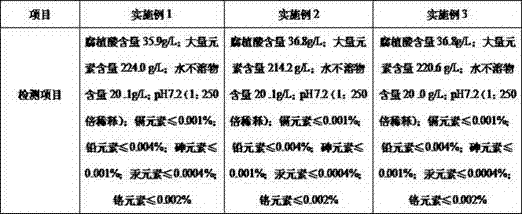

Examples

Embodiment 1

[0018] Step 1. Production of medium: production of Bacillus subtilis medium: add 1L distilled water, 20g glucose, 15g peptone, 5g sodium chloride, 0.5g beef extract, 20g agar and autoclave at 121°C for 20min; culture Aspergillus niger Preparation of the base: Add 5g of peptone, 1g of dipotassium hydrogen phosphate, 2g of yeast extract powder, 0.5g of magnesium sulfate, and 20g of glucose into 950ml of distilled water, dilute to 1L, and autoclave at 121°C for 20 minutes; Production of mold medium: 10g of peptone, 40g of glucose, heated and dissolved in 1000ml of distilled water, sterilized under high pressure at 121°C for 20 minutes;

[0019] Step 2: Activation of strains: inoculate the Bacillus subtilis slant strains into the Bacillus subtilis culture medium in a sterile environment, and incubate for 19 h at a shaking table speed of 170 r / min and a temperature of 36 °C. The Aspergillus niger slants were inoculated into the Aspergillus niger culture medium in a sterile environm...

Embodiment 2

[0025] Step 1. Production of medium: production of Bacillus subtilis medium: add 1L distilled water, 20g glucose, 15g peptone, 5g sodium chloride, 0.5g beef extract, 20g agar and autoclave at 121°C for 20min; culture Aspergillus niger Preparation of the base: Add 5g of peptone, 1g of dipotassium hydrogen phosphate, 2g of yeast extract powder, 0.5g of magnesium sulfate, and 20g of glucose into 950ml of distilled water, dilute to 1L, and autoclave at 121°C for 20 minutes; Production of mold medium: 10g of peptone, 40g of glucose, heated and dissolved in 1000ml of distilled water, sterilized under high pressure at 121°C for 20 minutes;

[0026] Step 2: Activation of strains: inoculate the Bacillus subtilis slant strains into the Bacillus subtilis culture medium in a sterile environment, and incubate for 19 h at a shaking table speed of 170 r / min and a temperature of 36 °C. The Aspergillus niger slants were inoculated into the Aspergillus niger culture medium in a sterile environm...

Embodiment 3

[0032] Step 1. Production of medium: production of Bacillus subtilis medium: add 1L distilled water, 20g glucose, 15g peptone, 5g sodium chloride, 0.5g beef extract, 20g agar and autoclave at 121°C for 20min; culture Aspergillus niger Preparation of the base: Add 5g of peptone, 1g of dipotassium hydrogen phosphate, 2g of yeast extract powder, 0.5g of magnesium sulfate, and 20g of glucose into 950ml of distilled water, dilute to 1L, and autoclave at 121°C for 20 minutes; Production of mold medium: 10g of peptone, 40g of glucose, heated and dissolved in 1000ml of distilled water, sterilized under high pressure at 121°C for 20 minutes;

[0033] Step 2: Activation of strains: inoculate the Bacillus subtilis slant strains into the Bacillus subtilis culture medium in a sterile environment, and incubate for 19 h at a shaking table speed of 170 r / min and a temperature of 36 °C. The Aspergillus niger slants were inoculated into the Aspergillus niger culture medium in a sterile environm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com