Feed rich in probiotics and active peptide and application of feed

A technology of active peptides and probiotics, applied in the application, animal feed, animal feed and other directions, can solve the problems of antibiotic accumulation, harm to human health, accumulation, etc., to achieve the effect of simple operation, short enzyme production cycle, and convenient large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The Bacillus licheniformis strain with the preservation number CGMCC No. 13109 and the Lactobacillus strain with the preservation number CGMCC No. 13110 were inoculated on the slant medium, and cultured in an incubator at 37° C. for 24 hours. Activate two generations. The formula of the Bacillus licheniformis slant medium is as follows: 1% peptone, 1% sodium chloride, 0.5% yeast extract and 2.5% agar, and the pH value is 7.0. Lactobacillus medium formula is as follows: 1% casein peptone, 1% beef extract, 0.5% yeast extract, 0.25% glucose, 0.5% sodium acetate, 0.2% diammonium citrate, 0.1% Tween 80, 0.2% dihydrogen phosphate Potassium, 0.2% anhydrous magnesium sulfate, 0.005% manganese sulfate, 2% calcium carbonate, 2.5% agar, the pH value is 6.4.

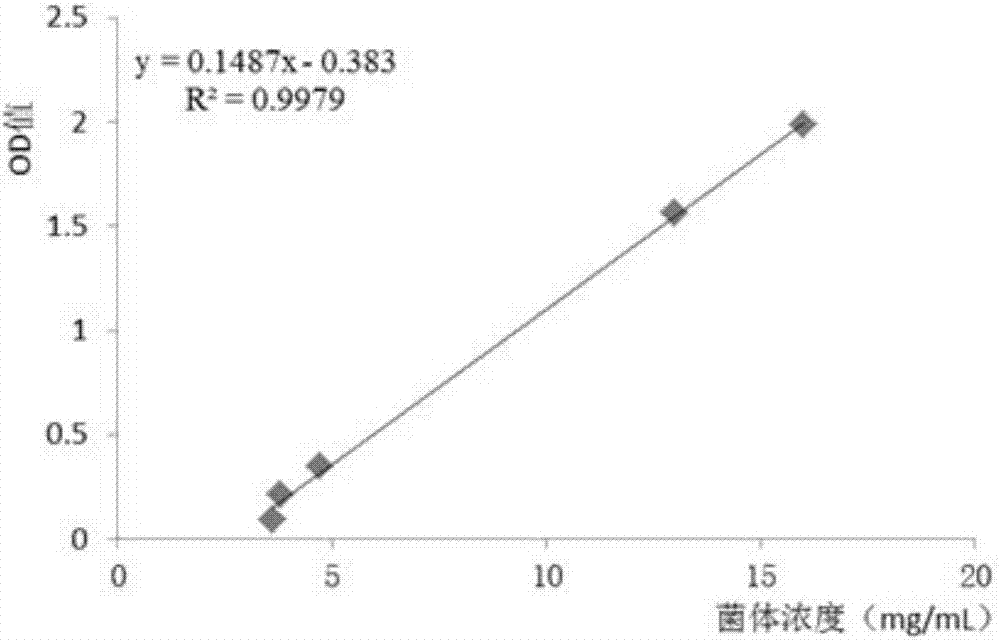

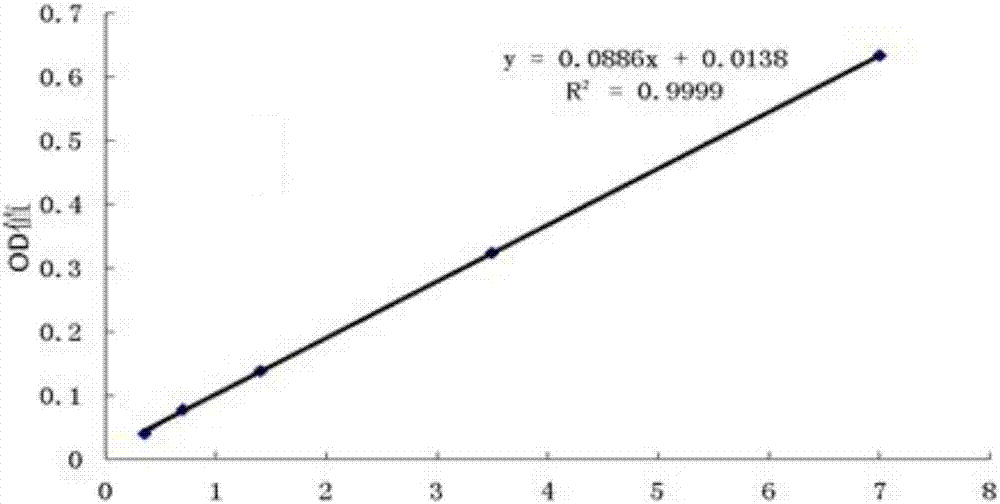

[0048] Inoculate the activated Bacillus licheniformis and Lactobacillus into the liquid seed medium according to the inoculation amount of 5%, and cultivate them on a shaking table with a rotation speed of 180r / min at 37°C f...

Embodiment 2

[0061] Mix corn gluten powder and bran in a mass ratio of 7:3 to form a mixture, the mass volume ratio of the mixture to water is 1g:1.3mL, and insert the Bacillus licheniformis and Lactobacillus prepared in Example 1 Seed solution, the inoculum of Bacillus licheniformis is 5×10 8 CFU / g feed liquid, the inoculation amount of Lactobacillus is 1×10 9 CFU / g feed solution, natural pH, temperature 37°C, first add Bacillus licheniformis for fermentation, then add Lactobacillus after 48h interval, and co-ferment for 48h to obtain the fermentation product.

[0062] (1) The content of soluble peptides in the fermentation product was detected by the Folin-phenol method.

[0063] (2) The oxidation resistance adopts pyrogallol autoxidation method.

[0064] Pyrogallol is stable in acidic environment, but autoxidation reaction occurs in weak alkaline environment,

[0065] Glycinol only accepts one electron to generate superoxide anion radical (O 2 +O 2 - ),and

[0066] In its autoxid...

Embodiment 3

[0083] Mix corn gluten powder and bran at a mass ratio of 3:2 to form a mixture, the mass volume ratio of the mixture to water is 1g:1.5mL, and insert the Bacillus licheniformis and Lactobacillus prepared in Example 1 Seed solution, the inoculum of Bacillus licheniformis was 1×10 9 The inoculation amount of CFU / g feed liquid and lactic acid bacteria is 1×10 10 CFU / g feed liquid, natural pH, temperature 35°C, first add Bacillus licheniformis, then add Lactobacillus after an interval of 36 hours, and co-ferment for 64 hours to obtain a fermentation product.

[0084] (1) The content of soluble peptides in the fermentation product was detected by the Folin-phenol method. The test result showed that the soluble peptide content was 94.02mg / g.

[0085] (2) According to the method described in Example 2, the oxidation resistance of the fermentation product was detected. The test results showed that the antioxidant activity of the fermentation product was 95U / mL.

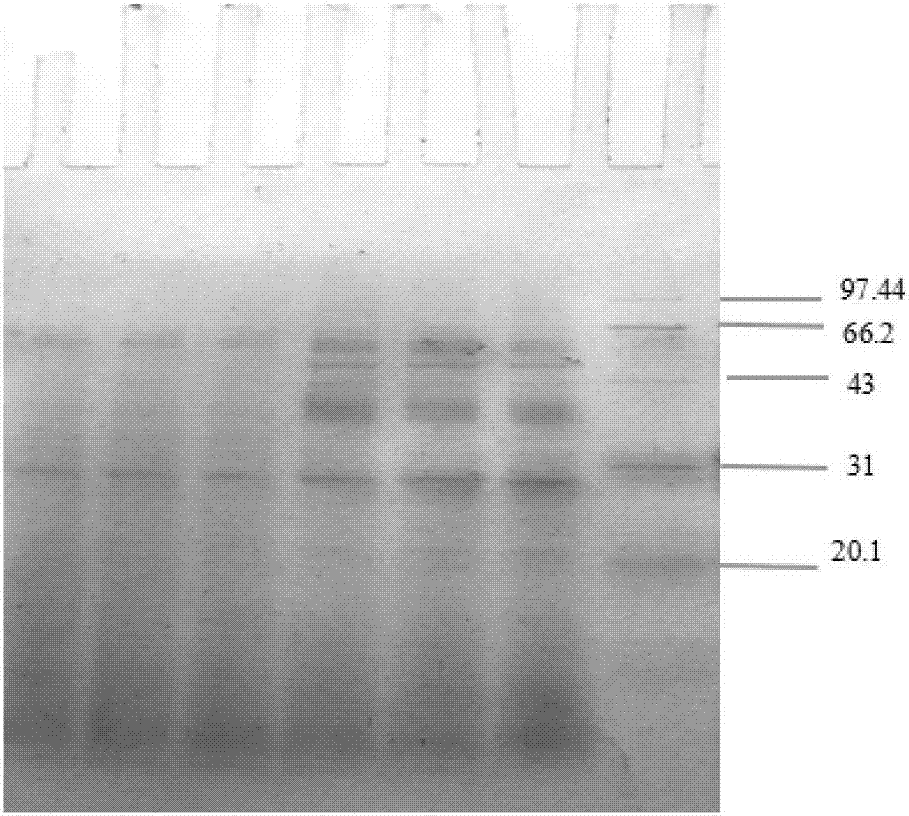

[0086] (3) Detect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com