Method for preparing inorganic compound melamine hard foaming nano-material

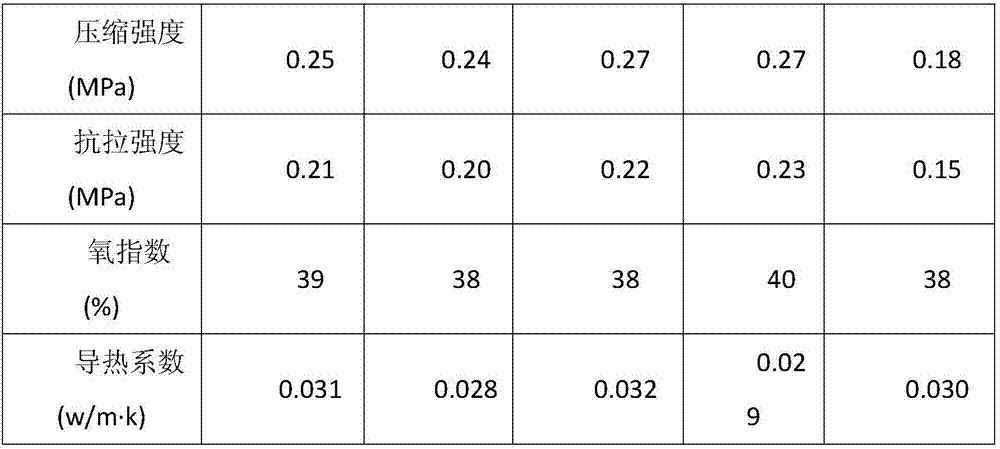

A technology for compounding melamine and inorganic nanomaterials is applied in the field of polymer foam materials, which can solve the problems of not very obvious effect, easy powder loss of materials, insufficient strength, etc., and achieve excellent mechanical properties and flame retardant properties, mild reaction process, and toughness. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

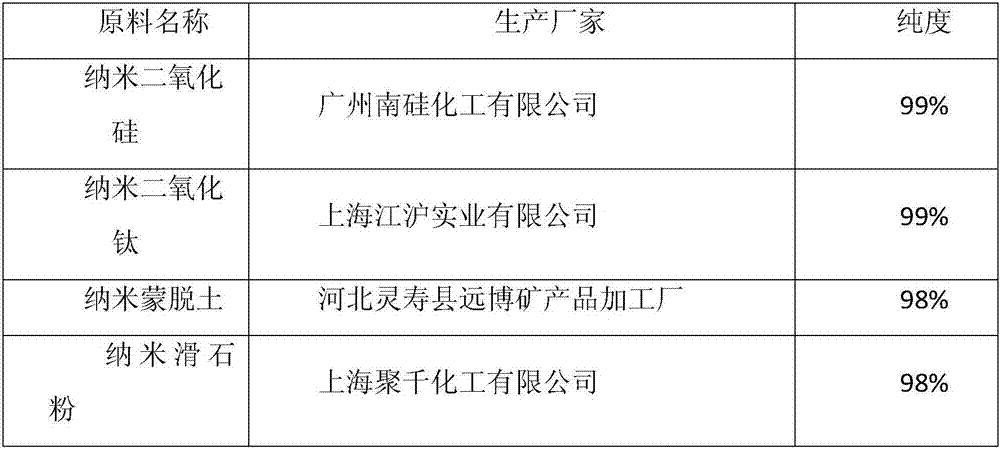

Method used

Image

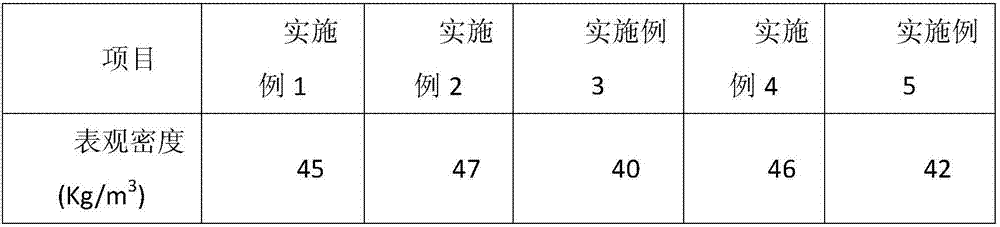

Examples

Embodiment 1

[0037] An inorganic nanocomposite melamine rigid foam material is prepared according to the following steps:

[0038] A. Add 3 mol of paraformaldehyde and 6.0 mol of water into the reactor, add dropwise triethanolamine, adjust the pH to 8.5, then add 1 mol of melamine, heat up to 80°C, and stir for 1.5 hours to obtain polyhydroxymelamine;

[0039] B, in the polyhydroxy melamine, drop into the hydrochloric acid that massfraction is 2%, regulate system pH value to 6.5; Then add 2.52g nano silicon dioxide (0.02 times of melamine quality) and 12.6g polycyanamide under the condition of 60~70 ℃ Ethylene glycol (0.1 times the mass of melamine), acidic polymerization reaction at 65 ° C, polymerization reaction 1.0h, a three-dimensional network polymerization reaction occurs, until the reaction solution is slightly turbid, to obtain a prepolymer resin solution;

[0040] C, under room temperature, in the prepolymer resin solution, add the emulsifier sodium dodecylbenzene sulfonate, 5% b...

Embodiment 2

[0042] An inorganic nanocomposite melamine rigid foam material is prepared according to the following steps:

[0043]A. Add 3.5 mol of paraformaldehyde and 5.5 mol of water into the reactor, add dropwise a 20% sodium hydroxide solution, adjust the pH to 9.0, then add 1 mol of melamine, raise the temperature to 90°C, and stir for 1.5 hours , namely polyhydroxymelamine;

[0044] B, in the polyhydroxy melamine, drip the hydrochloric acid that mass fraction is 2%, regulate system pH value to 6.0; Then add 1.26g nano titanium dioxide (0.01 times of melamine quality) and 6.31g polyvinyl alcohol under the condition of 70~80 ℃ (0.05 times the mass of melamine), acidic polymerization reaction was carried out at 75°C, the polymerization reaction was 1.0h, and a three-dimensional network polymerization reaction occurred until the reaction solution was slightly turbid to obtain a prepolymer resin solution;

[0045] C, under room temperature, in prepolymer resin solution, adding weight is...

Embodiment 3

[0047] An inorganic nanocomposite melamine rigid foam material is prepared according to the following steps:

[0048] A. Add 4mol paraformaldehyde and 6.0mol water into the reactor, add triethylamine dropwise, adjust the pH value to 8.0, then add 1mol melamine, heat up to 80°C, and stir for 1.5h to obtain polyhydroxymelamine;

[0049] B, in polyhydroxy melamine, drip the hydrochloric acid that massfraction is 2%, regulate system pH value to 5.5; Then add 1.89g nanometer montmorillonite (0.015 times of melamine quality) and 15.13g on the condition of 60~70 ℃ Toluenesulfonamide (0.12 times the mass of melamine) was subjected to an acidic polymerization reaction at 65° C. for 1.0 h, and a three-dimensional network polymerization reaction occurred until the reaction solution was slightly turbid to obtain a prepolymer resin solution;

[0050] C, under room temperature, in prepolymer resin solution, adding weight is the emulsifier fatty alcohol polyoxyethylene ether sodium sulfate o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com