Epoxy resin composition containing vanillic aldehyde-based phosphorus containing flame retardant and application thereof

A technology of epoxy resin and vanillin, which is applied in the fields of compounds of group 5/15 elements of the periodic table, organic chemistry, chemical instruments and methods, etc., can solve problems such as complex preparation process, and achieve simple preparation process and high mechanical properties Excellent, the effect of alleviating the oil crisis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

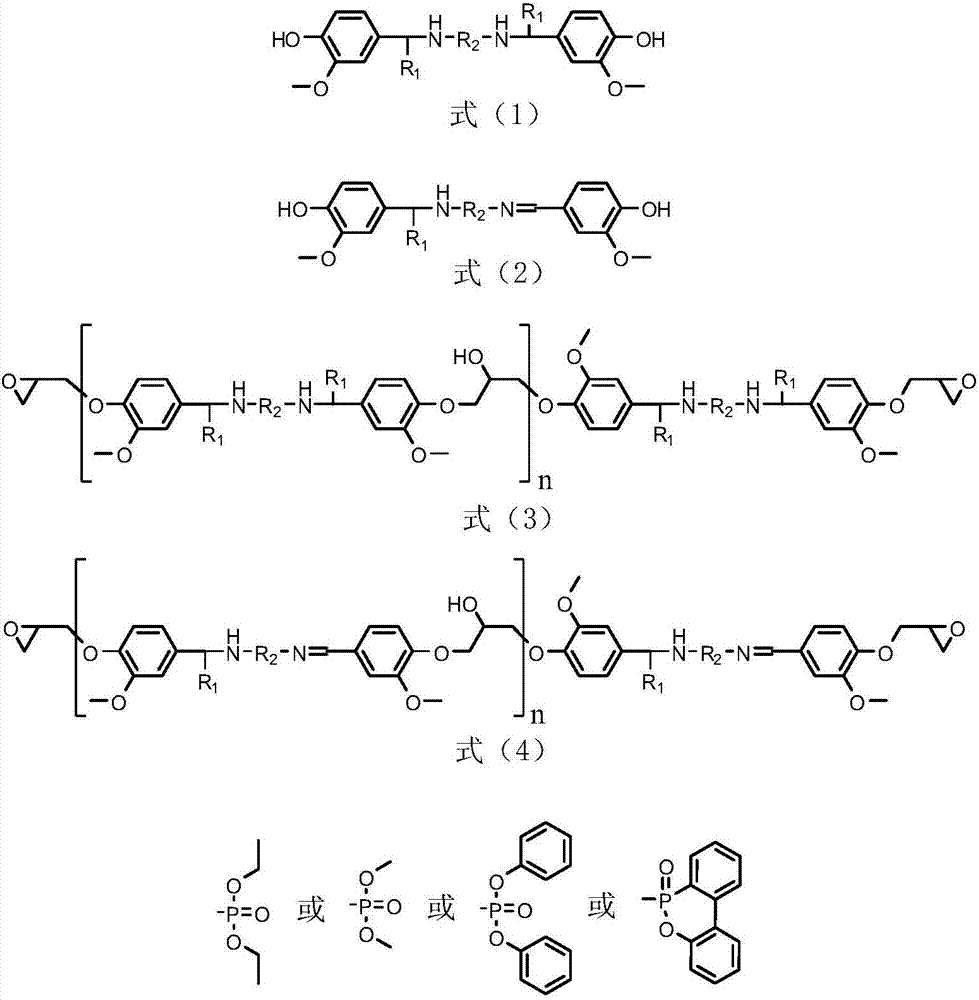

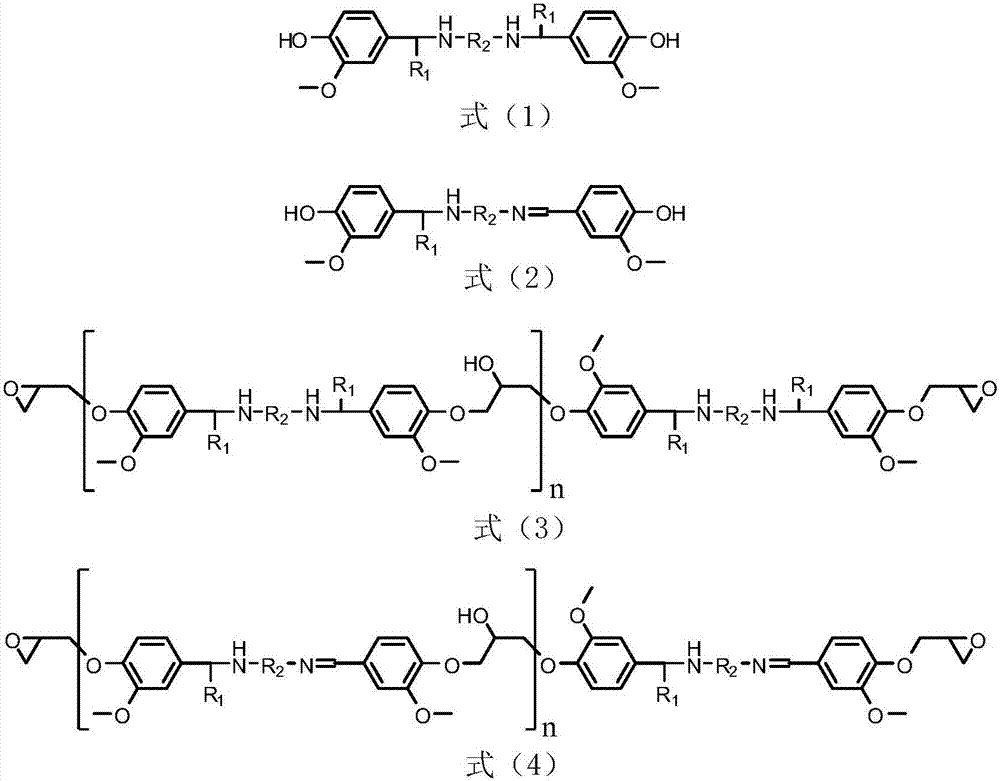

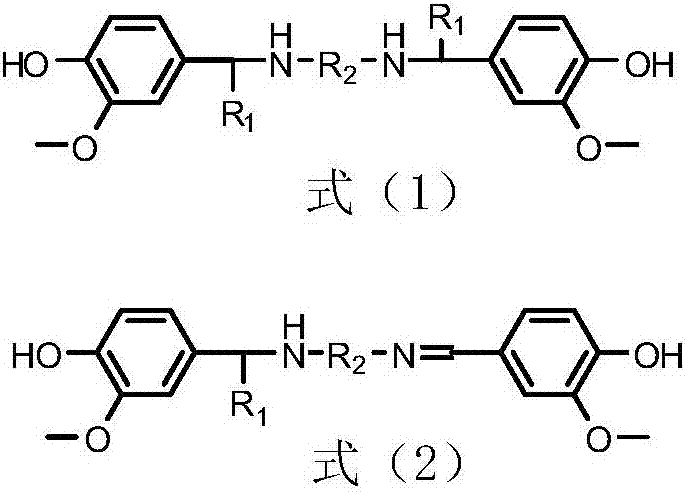

[0028] Further, the preparation method may further include: uniformly mixing the vanillin-based phosphorus-containing bisphenol, epichlorohydrin and alkaline substances, and then reacting at 20-120° C. for 0.2-48 hours to obtain the vanillin-based phosphorus-containing bisphenol An epoxy compound, the vanillin-based phosphorus-containing epoxy compound has a structure shown in formula (3) or formula (4);

[0029]

[0030] Among them, R 1 include

[0031] R 2 Including straight-chain alkanes or aromatic hydrocarbons or alicyclic alkanes with more than 2 to 20 carbon atoms, 0≤n≤10.

[0032] As one of the preferred embodiments, the mass ratio of vanillin, diamine compound, phosphorus-containing compound, catalyst and organic solvent is 100: (15-100): (20-300): (0-15): (50 ~500).

[0033] As one of the preferred embodiments, the mass ratio of the vanillin-based phosphorus-containing bisphenol, epichlorohydrin and alkaline substance is 100:(20-500):(30-300).

[0034] As o...

Embodiment 1

[0050] (1) React 100g of vanillin, 36g of p-phenylenediamine, and 500mL of ethanol at 40°C for 1 hour, then add 2.5g of zinc chloride and 72g of dimethyl phosphite, heat up to 80°C and react for 3 hours, petroleum ether precipitates, After washing with ethanol, the vanillin-based phosphorus-containing bisphenol represented by the following formula (5) was obtained. According to the hydrogen nuclear magnetic resonance spectrum figure of this vanillin-based phosphorus-containing bisphenol, it can be known that in 1 In H nuclear magnetic resonance (d6-DMSO is the solvent), 6.7-7.1ppm represents the proton peak on the benzene ring of the vanillin structure, 6.5ppm represents the proton peak on the benzene ring of the p-phenylenediamine structure, and 3.8ppm is the methyl group of the vanillin structure proton peak on the .

[0051]

[0052] (2) Mix 100g of bisphenol-A epoxy resin (E-51), 15g of ammonium polyphosphate and 0.5g of vanillin-based phosphorus-containing bisphenol s...

Embodiment 2

[0059] (1) React 100g of vanillin, 36g of p-cyclohexanediamine, and 500mL of ethanol at 40°C for 1 hour, then add 2.5g of zinc chloride and 154g of diphenyl phosphite, raise the temperature to 90°C for 2 hours, and precipitate petroleum ether , after washing with ethanol, obtain the vanillin-based phosphorus-containing bisphenol shown in the following formula (6). According to the hydrogen nuclear magnetic resonance spectrum figure of this vanillin-based phosphorus-containing bisphenol, it can be known that in 1 In H NMR (d6-DMSO is a solvent), 6.6-7.4ppm represents the proton peak on the benzene ring of diphenyl phosphite and vanillin structure, and 2.6ppm represents the proton peak on the carbon connected to the imine group on the alicyclic ring, 1.2-1.8ppm is the chemical shift of the proton on the methylene group of the 1,4-cyclohexanediamine structure, and 3.7ppm is the proton peak on the methyl group of the vanillin structure.

[0060]

[0061] (2) Mix 100 g of glyci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com