Completely-organic perovskite nano-sheet, and preparation method and application thereof

A technology of inorganic calcium and nanosheets, applied in the field of nanomaterials, has achieved good application prospects, huge application potential, and good size uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

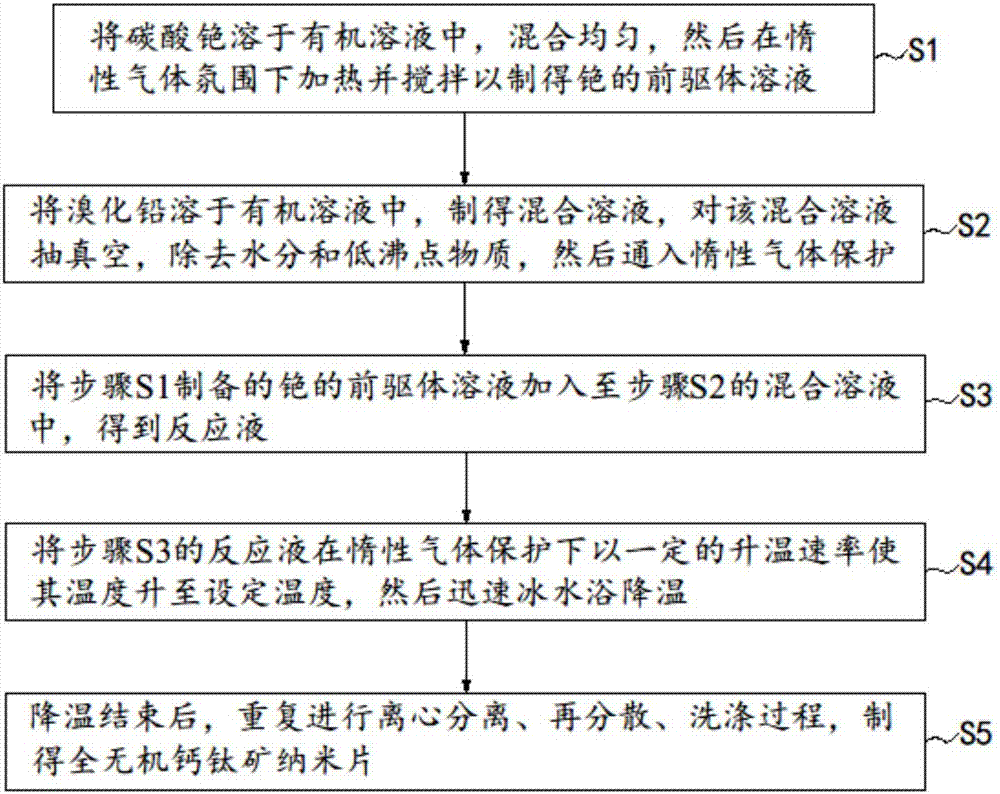

[0035] The invention provides a method for preparing all-inorganic perovskite nanosheets, the method comprising the following steps:

[0036] S1. dissolving cesium carbonate in an organic solvent containing oleic acid and octadecene, mixing uniformly, then heating and stirring under an inert gas atmosphere to obtain a cesium oleate solution;

[0037] S2. lead bromide is dissolved in containing oleic acid and oleylamine organic solvent, makes mixed solution, and the reactor that fills this mixed solution is connected to vacuum device, vacuumizes, to remove the impurity in organic solvent (remove Moisture and low boiling point substances), and then pass through the inert gas protection;

[0038] The solutions of steps S1 and S2 were both prepared in a glove box.

[0039] S3. Add the cesium oleate solution prepared in step S1 to the mixed solution in step S2 to obtain a reaction solution;

[0040] S4. The temperature of the reaction solution in step S3 is raised to a set temper...

Embodiment 1

[0051] Such as figure 1 As shown, this embodiment provides an all-inorganic CsPbBr 3 A method for preparing a perovskite nanosheet, comprising the following steps:

[0052] S1. Weigh 0.16g of cesium carbonate solid powder in a glove box and dissolve it in a reactor containing 6mL of octadecene and 0.5mL of oleic acid, raise the temperature to 150°C under the protection of an inert gas and stir to mix evenly to prepare mixture. A three-necked flask can be used as the reactor. After the solution is mixed evenly, the temperature is lowered to 120°C for use.

[0053] In the above system, octadecene acts as a solvent, and high temperature is used to make oleic acid and cesium carbonate fully act to prepare a cesium precursor solution, namely cesium oleate solution. Certainly, the solvent is not limited to the octadecene in this embodiment, and an organic compound containing less than 18 carbons can also be selected as the solvent according to the carbon chain length and the hydr...

Embodiment 2

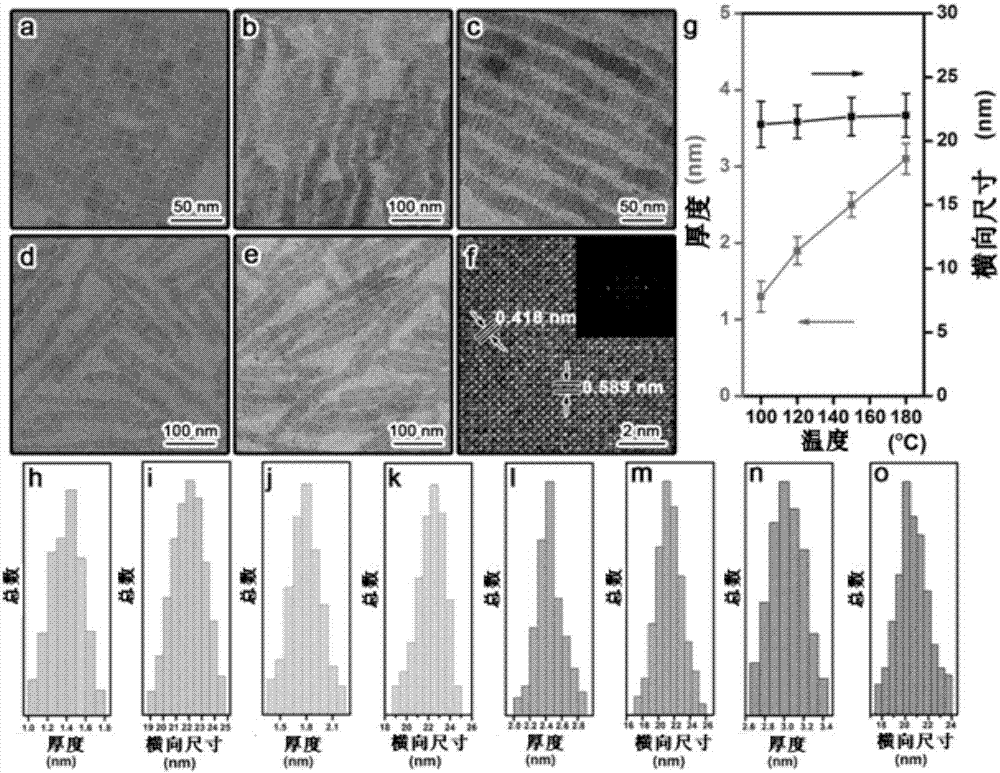

[0061] The all-inorganic CsPbBr provided by this embodiment 3 The method for preparing perovskite nanosheets differs from Example 1 in that: in step S4, the reaction solution is slowly heated up to 100°C at a rate of 20°C / min under the protection of an inert gas, and immediately freezes within 5 seconds. Cool down in a water bath. The rest of the steps are the same as those in Embodiment 1, and will not be repeated here.

[0062] Such as figure 2 Shown in (b), the CsPbBr with 2 atomic layer thickness prepared by the preparation method of the present embodiment 3 Transmission electron micrograph of perovskite nanoflakes, it can be seen from the figure that the prepared CsPbBr 3 The perovskite nanoflakes have a uniform thickness, enabling them to be ordered into a self-assembled structure; figure 2 (h) and 2(i) are the obtained CsPbBr 3 The thickness and lateral size distribution diagram of perovskite nanoflakes, it can be seen from the figure that the CsPbBr prepared in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Horizontal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com