Dielectric particle for giant electrorheological fluid and preparation method of dielectric particle

A technology of giant electrorheological fluid and dielectric particles, applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problems of large wear of electrorheological devices, poor particle suspension stability, poor high and low temperature stability, etc., and achieve no corrosion of devices. , the effect of improving anti-settling performance and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

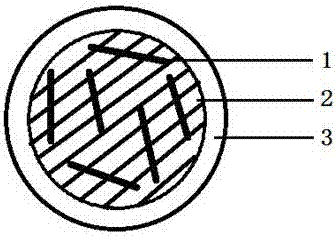

Image

Examples

Embodiment 1

[0030] Proceed as follows:

[0031] (1) Dissolve 60mL of isopropyl titanate in 60mL of absolute ethanol, stir at room temperature for 30min, and obtain a uniform solution, which is designated as liquid A.

[0032] (2) Dissolve 1.0 g of polyvinyl fluoride in 15 mL of absolute ethanol, stir at room temperature for 20 min, and obtain a homogeneous solution, which is designated as liquid B.

[0033] (3) Add liquid B to liquid A drop by drop, control the titration rate of the solution to 0.25mL / min (control the reaction process not less than 1h); react until no white precipitate is produced, wash with absolute ethanol to remove the white precipitate Impurities.

[0034] (4) The white precipitate in step (3) was vacuum-dried at 80° C. for 2 hours to obtain the desired polyimide-doped titanium dioxide.

[0035] (5) Dissolve 1.5g of polyaniline in 15mL of absolute ethanol, heat in a water bath to 55°C, stir until completely dissolved, and cool to room temperature.

[0036] (6) Add ...

Embodiment 2

[0041] Proceed as follows:

[0042] (1) Dissolve 100mL butyl titanate in 100mL absolute ethanol, stir at room temperature for 50min, and obtain a uniform solution, which is designated as liquid A.

[0043] (2) Dissolve 1.6g of polyvinylidene fluoride in 20mL of absolute ethanol, stir at room temperature for 30min, and obtain a homogeneous solution, which is designated as liquid B.

[0044] (3) Add liquid B to liquid A drop by drop, control the titration rate of the solution to 0.35mL / min (control the reaction process not less than 1h); react until no white precipitate is produced, wash with absolute ethanol to remove the white precipitate Impurities.

[0045] (4) The white precipitate in step (3) was vacuum-dried at 70°C for 3 hours to obtain polyvinylidene fluoride-doped titanium dioxide.

[0046](5) Dissolve 1.3g of polyacrylonitrile in 15mL of absolute ethanol, heat in a water bath to 50°C, stir until completely dissolved, and cool to room temperature.

[0047] (6) Add t...

Embodiment 3

[0052] Proceed as follows:

[0053] (1) Dissolve 120 mL of tetraester titanate in 120 mL of absolute ethanol, stir at room temperature for 60 min, and obtain a uniform solution, which is designated as liquid A.

[0054] (2) Dissolve 0.8g of polyimide in 12mL of absolute ethanol, stir at room temperature for 18min, and obtain a homogeneous solution, which is designated as liquid B.

[0055] (3) Add liquid B to liquid A drop by drop, control the titration rate of the solution to 0.18mL / min (control the reaction process not less than 1h); react until no white precipitate is produced, wash with absolute ethanol to remove the white precipitate Impurities.

[0056] (4) Dry the white precipitate in step (3) in vacuum at 60° C. for 5 hours, which is polyimide-doped titanium dioxide.

[0057] (5) Dissolve 1.3g of polyethylene terephthalate in 18mL of absolute ethanol, heat in a water bath to 55°C, stir until completely dissolved, and cool to room temperature.

[0058] (6) Add the po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com