N-butane isomerization catalyst and preparation method thereof

A technology for isomerization and n-butane, which is applied in the field of n-butane isomerization catalyst and its preparation, can solve the problems of high reaction temperature and large energy consumption, and achieves low reaction temperature, high n-butane isomerization activity, Good reproducibility and catalytic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The present embodiment provides a kind of preparation method of n-butane isomerization catalyst, it comprises the following steps:

[0055] (1) Preparation of nano-scale tetragonal zirconia support

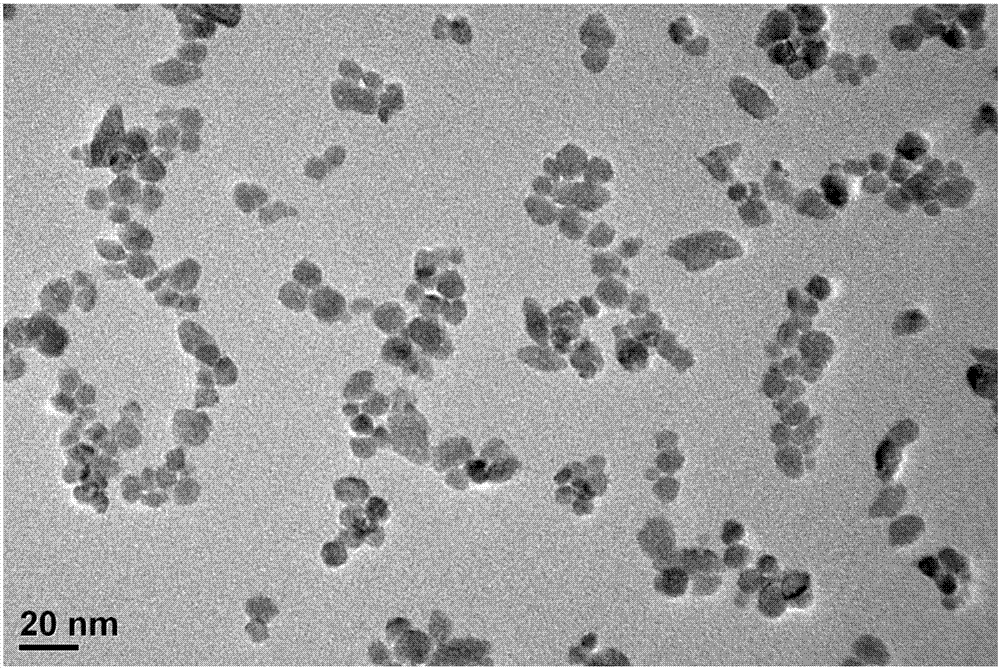

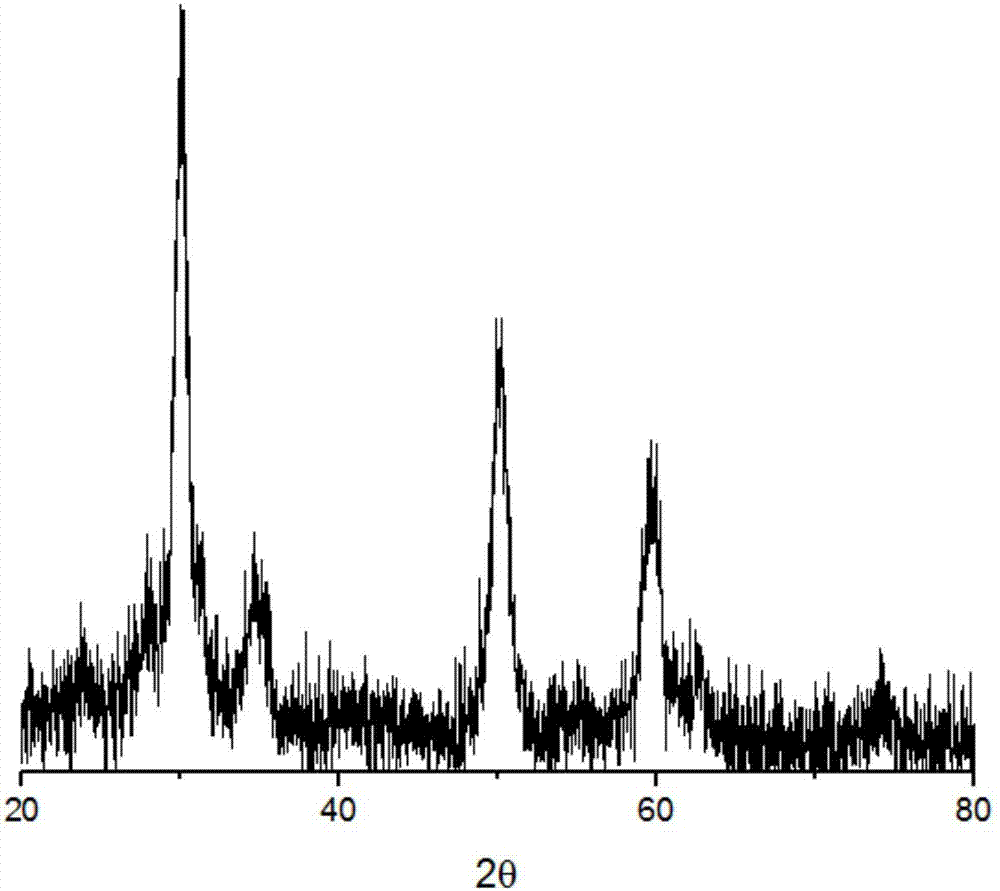

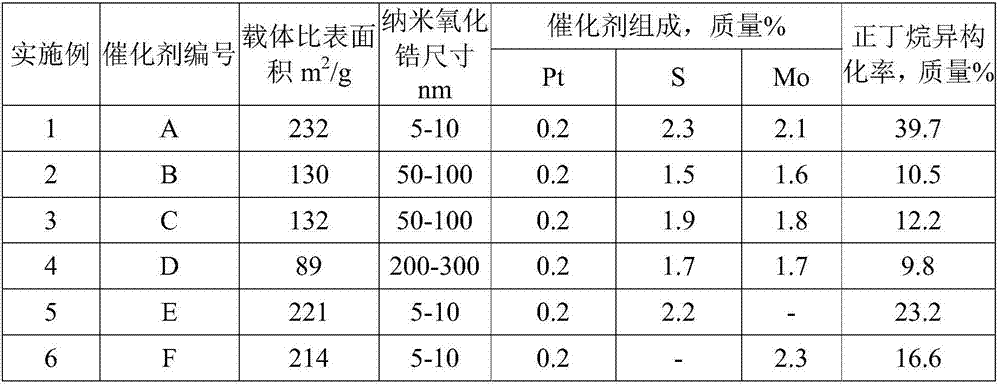

[0056] Get zirconium oxychloride and lanthanum nitrate to be dissolved in deionized water (concentration of zirconium is 0.4mol / L, and the content of lanthanum is 2% (w)), while stirring, drip the ammoniacal liquor that concentration is 10% to adjust pH, make solution pH = 7-8, then moved into a hydrothermal kettle, hydrothermally reacted at 170°C for 24 hours; after cooling down, filtered and washed with a Buchner funnel, and dried at 110°C for 24 hours to obtain a nano-sized tetragonal zirconia carrier. figure 1 It is a nanoscale tetragonal zirconia support electron micrograph, figure 2 It is the XRD spectrum of nano-sized tetragonal zirconia.

[0057] (2) Composite pickling molding

[0058] The nanoscale tetragonal phase zirconia carrier prepared in step (1) is confi...

Embodiment 2

[0062] Identical with embodiment 1 operating method, difference is (1) step takes zirconium oxychloride to be dissolved in deionized water (concentration of zirconium is 0.4mol / L, and the content of lanthanum is 0% (w)) and makes catalyst B, Its active component content and n-butane isomerization rate are shown in Table 1.

Embodiment 3

[0064] The operation method is the same as in Example 1, except that (1) the step is to dissolve zirconium oxychloride in deionized water, and while stirring, dropwise add ammonia water with a concentration of 10% to adjust the pH to make the solution pH=7-8, and then move into Hydrothermal kettle, hydrothermal reaction at 170°C for 24 hours; after cooling down, use a Buchner funnel to filter and wash, then dip lanthanum nitrate into an aqueous solution, then filter and wash, and dry at 110°C for 24 hours (the concentration of zirconium is 0.4mol / L, The content of lanthanum is 2% (w)) and catalyst C is prepared, and its active component content and n-butane isomerization rate are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com