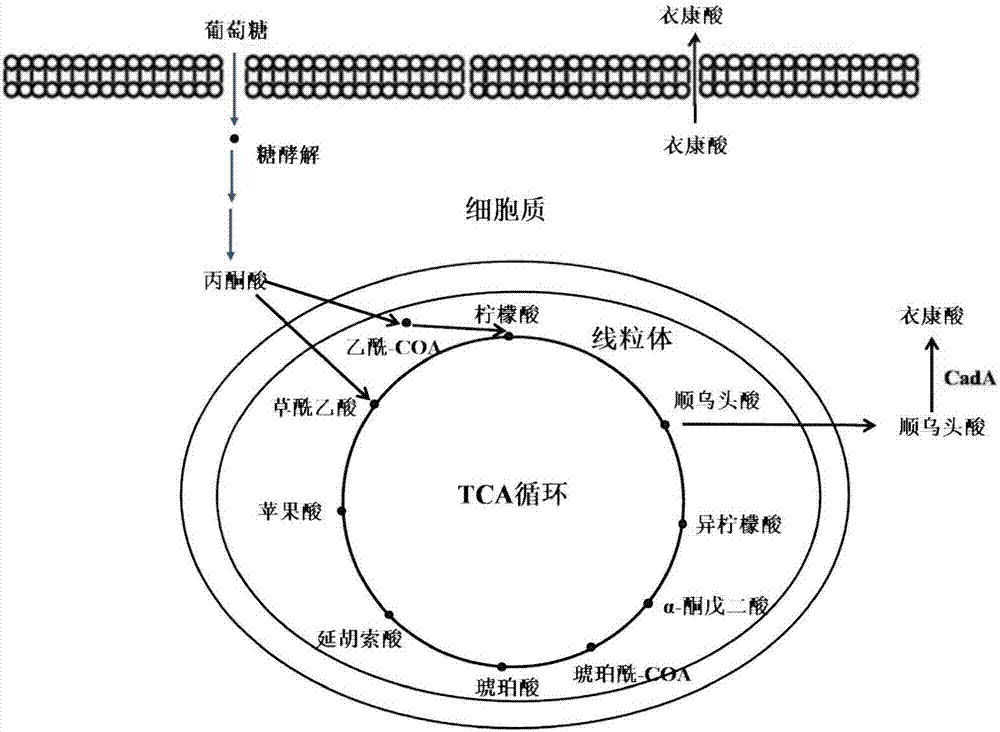

Recombinant yeast strain for generating itaconic acid, and construction method and application thereof

A yeast strain and itaconic acid-producing technology, applied in the field of genetic engineering, can solve the problems of slow growth of Aspergillus terreus, influence on bacterial growth, long fermentation cycle, etc., and achieve strong tolerance, strong application value, and clear purpose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

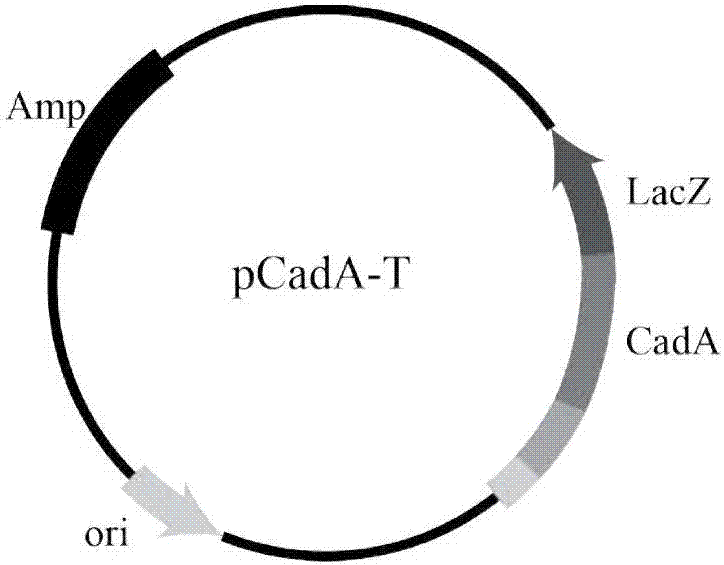

[0018] Embodiment 1 Construction of cis-aconitic acid decarboxylase gene cadA expression cassette

[0019] 1.1 Cloning of the aconitic acid decarboxylase gene from Aspergillus terreus

[0020] The Aspergillus terreus CICC 40205 strain used in the present invention comes from the China Industrial Microorganism Strain Collection Center. Primers cadA-F (5'-AAGGGATCCATGACCAAACAATCTGCGGAC-3') and cadA-R (5'-CGAGGTACCTTATACCAGTGGCGATTTCA-3') were designed according to the information published in the Aspergillus terreus FGSC A1156 genome database, and the cDNA of A. Aconitic acid decarboxylase gene, the length of the target fragment detected by 1.0% agarose gel electrophoresis is about 1.5kb, the target product is recovered and purified by tapping gel and ligated with pMD19-T to obtain the recombinant plasmid pCadA-T containing the cadA gene sequence. The pCadA-T was sequenced, and the sequencing results showed that the cloned DNA fragment was the Aconitate decarboxylase gene of As...

example 2

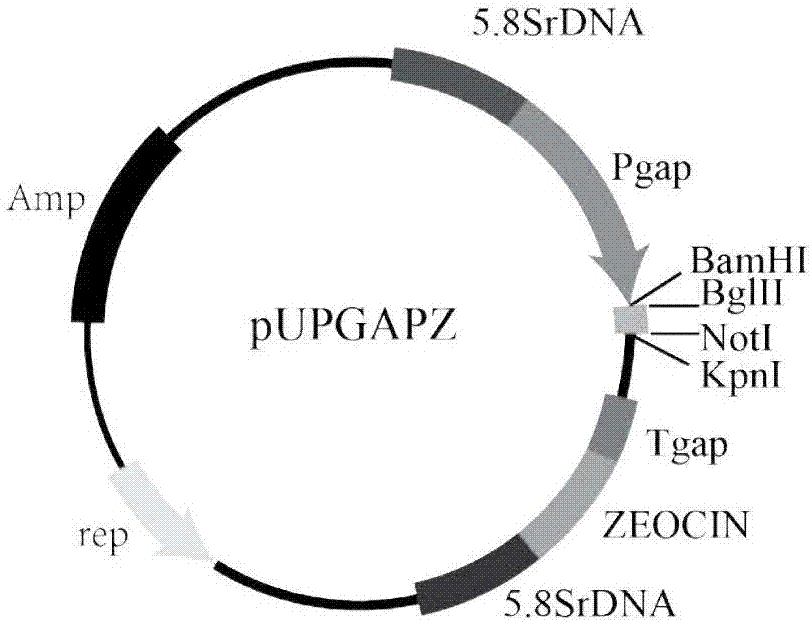

[0023] Example 2 prepares the recombinant yeast strain containing Pgap-CadA-Tgap-zeocin expression cassette

[0024] 2.1 Obtaining the recombinant yeast strain containing Pgap-CadA-Tgap-zeocin expression cassette

[0025] 1) Extract the recombinant plasmid pURGAPZC, and linearize it with HindIII restriction enzyme.

[0026] 2) Pick one ring of glycerologenic Candida strain and insert it into the seed medium (yeast powder 10g / L, peptone 20g / L, glucose 20g / L, zeocin 150μg / mL, the balance is water), at 30°C, Under the condition of 200r / min, shake culture for 18h to obtain liquid seeds. Insert the obtained liquid seeds into the seed culture medium according to the inoculum amount of 1% (v / v), the liquid filling volume is 10mL / 100mL, the fermentation temperature is controlled at 30°C, the rotation speed is 200r / min, and cultured until OD 600 is 1. Take 1 mL of bacteria, collect the cells by centrifugation, discard the supernatant, resuspend the cells in 1 mL of sterile water, an...

example 3

[0029] Example 3 Recombinant Yeast Strain Production of Itaconic Acid

[0030] 1) Preparation of seed medium: glucose 20g / L, yeast powder 10g / L, peptone 5g / L, zeocin 150μg / mL, the balance is water; itaconic acid fermentation medium: glucose 50g / L, yeast powder 10g / L , peptone 20g / L, zeocin 150μg / mL, and the balance is water.

[0031] 2) Inoculate the recombinant yeast strain obtained above into the seed culture medium, and vibrate at 30° C. and 200 r / min for 18 hours to obtain liquid seeds. The obtained liquid seeds were inserted into the fermentation medium at an inoculum size of 4% (v / v), filled with 30mL / 250mL, the controlled fermentation temperature was 30°C, the rotating speed was 200r / min, the time was 48h, and the fermentation ended.

[0032] The content of itaconic acid in the fermentation broth was detected by high performance liquid chromatography (HPLC). Instrument: Agilent high performance liquid chromatography (with UV-visible detector, differential detector and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com