Preparation method of honeycomb denitration catalyst with improved specific surface area

A technology of denitrification catalyst and specific surface area, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, heterogeneous catalyst chemical elements, etc., can solve the problem of active center imbalance, achieve improved efficiency, stable catalyst activity, and increase strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

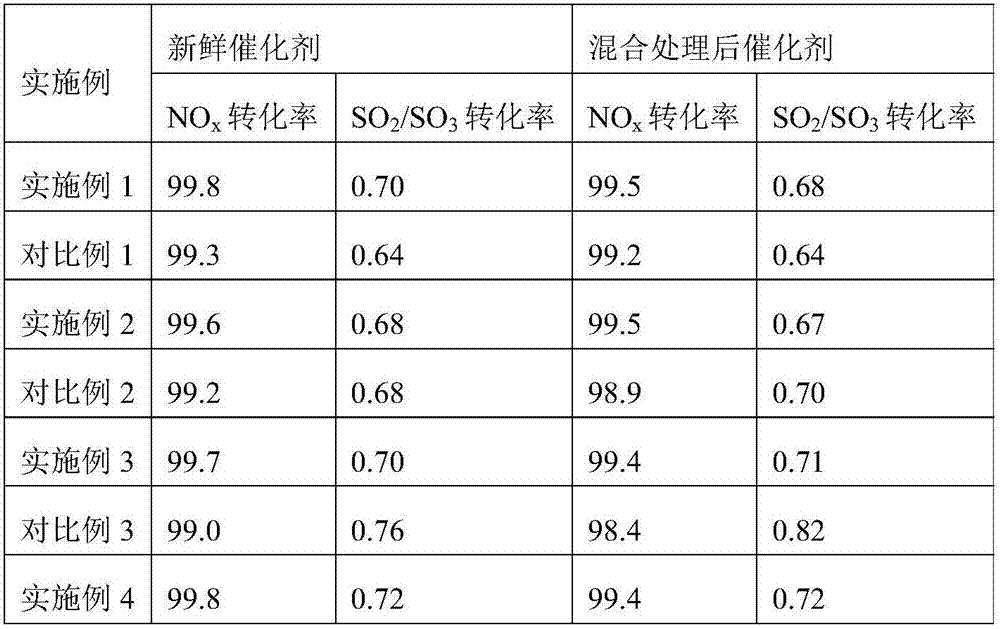

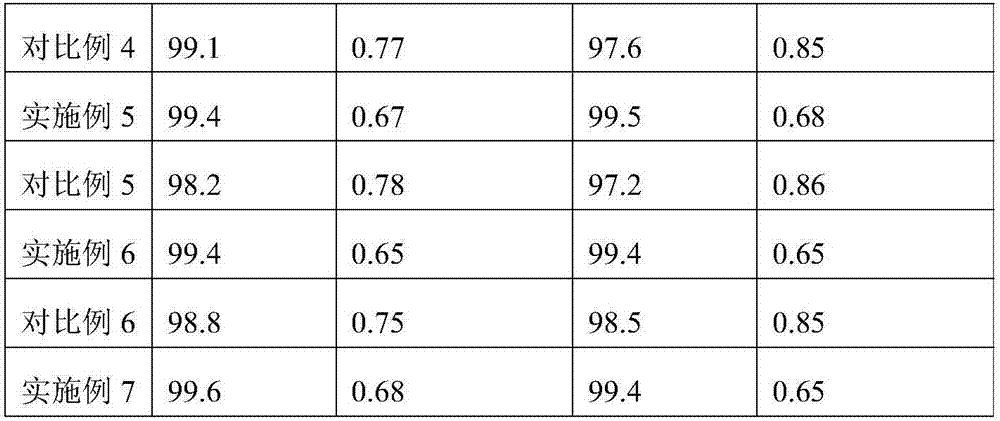

Examples

Embodiment 1

[0048] Add 20g of coconut shell activated carbon into the glucose solution, mix well and beat to form a slurry, and will contain TiO 2 500g of titanyl sulfate is dissolved in sulfuric acid solution to form TiO 2 For a 35g / L solution, add WO 3 Measure 10g of ammonium paratungstate solution, ultrasonically oscillate for 2 hours, then gradually add ammonia water to adjust the pH value to 9.5, after the precipitation is complete, filter and wash; then use deionized water to make a slurry with a water content of 50%, and add V 2 o 5 A total of 5g of ammonium metavanadate solution was stirred and ultrasonically oscillated for 1.5h. After direct drying, it was roasted at 620°C for 6h in a nitrogen atmosphere; after roasting, the powder was mixed with MoO 3 A total of 10g of ammonium molybdate was formulated into a slurry with a water content of 30%. After stirring, 4g of scallop powder was added, stirred for 40min, sealed and left for 24h, extruded into a honeycomb shape, dried, an...

Embodiment 2

[0052] Add 15g of coconut shell activated carbon into the glucose solution, mix well and beat to form a slurry, and will contain TiO 2 500g of titanyl sulfate is dissolved in sulfuric acid solution to form TiO 2 For a 35g / L solution, add WO 3 A total of 20g of ammonium paratungstate solution, after mechanical stirring for 2 hours, gradually add ammonia water to adjust the pH value to 9.0, after the precipitation is complete, filter and wash; then use deionized water to make a slurry with a water content of 50%, and add V 2 o 5 A total of 10g of ammonium metavanadate solution was stirred mechanically for 1.5h, and after direct drying, it was roasted at 500°C for 6h in a nitrogen atmosphere; after roasting, the powder was mixed with MoO 3 A total of 2.5g of ammonium molybdate was formulated into a slurry with a water content of 30%. After stirring, 3g of scallop powder was added, stirred for 40min, sealed and left for 10h, extruded into a honeycomb shape, dried, and then coate...

Embodiment 3

[0056] Add 20g of coconut shell activated carbon into the glucose solution, mix well and beat to form a slurry, and will contain TiO 2 500g of titanyl sulfate is dissolved in sulfuric acid solution to form TiO 2 For 40g / L solution, add WO 3 A total of 15g of ammonium paratungstate solution, after ultrasonic vibration for 1 hour, gradually add ammonia water to adjust the pH value to 9.0, after the precipitation is complete, filter and wash; then use deionized water to make a slurry with a water content of 50%, and add V 2 o 5 A total of 20g of ammonium metavanadate solution was stirred and ultrasonically oscillated for 1.5h. After direct drying, it was roasted at 400°C for 6h in a nitrogen atmosphere; after roasting, the powder was mixed with MoO 3 A total of 3g of ammonium molybdate was formulated into a slurry with a water content of 30%. After stirring, 4g of safflower powder was added, stirred for 40min, sealed and left for 10h, extruded into a honeycomb shape, dried, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com