Lithium ion battery negative electrode material silicon oxide doped manganese oxide/carbon tube and preparation method thereof

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of low material specific capacity, complicated preparation steps, and poor performance, and achieve high ion conductivity and simple preparation process , the effect of low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

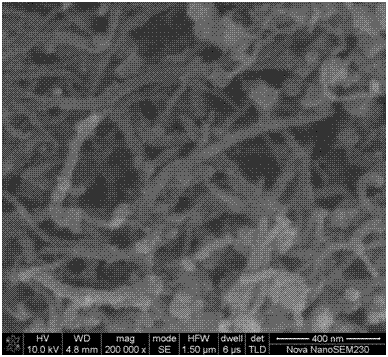

[0035] (1) Disperse 10mg of carbon nanotubes in a low-carbon alcohol solution of N,N-dimethylformamide (mixed with 25mL of ethanol and 25mL of N,N-dimethylformamide) to obtain a carbon nanotube dispersion ;

[0036] (2) Dissolve 151mg of manganese sulfate (1mmol), 2g of urea (33.30mmol) and 35μL of ethyl orthosilicate (0.16mmol) in the carbon nanotube dispersion obtained in step (1), stir well, and then fill it into 100 mL Put it in a stainless steel reaction kettle lined with polytetrafluoroethylene, place it in a drying oven, and conduct a hydrothermal reaction at 180°C for 4 hours, then cool it down to room temperature naturally, filter, and wash the precipitate with absolute ethanol and deionized water respectively. 3 times, freeze-dried at -45°C and vacuum degree of 35Pa for 48 hours to obtain black powder;

[0037] (3) The black powder obtained in step (2) was calcined in high-purity argon at 800°C for 2 hours, and cooled to room temperature with the furnace to obtain s...

Embodiment 2

[0043] (1) Disperse 20mg of carbon nanotubes in a low-carbon alcohol solution of N,N-dimethylformamide (mixed with 20mL of ethanol and 30mL of N,N-dimethylformamide) to obtain carbon nanotube dispersion liquid;

[0044] (2) Dissolve 357.9 mg of manganese nitrate (2 mmol), 5 g of glycine (66.60 mmol) and 55 μL of ethyl orthosilicate (0.25 mmol) in the carbon nanotube dispersion obtained in step (1), stir evenly, and then fill 100 Put it in a stainless steel reaction kettle lined with polytetrafluoroethylene, place it in a drying oven, and conduct a hydrothermal reaction at 180°C for 6 hours, then naturally cool to room temperature, filter, and wash with absolute ethanol and deionized water respectively Precipitate 3 times, freeze-dry at -45°C, vacuum 35Pa for 48h to obtain black powder;

[0045] (3) The black powder obtained in step (2) was calcined in high-purity argon at 750°C for 3 hours, and cooled to room temperature with the furnace to obtain silicon oxide-doped manganes...

Embodiment 3

[0050] (1) Disperse 10mg of carbon nanotubes in a low-carbon alcohol solution of N,N-dimethylformamide (mixed with 20mL of methanol and 40mL of N,N-dimethylformamide) to obtain carbon nanotube dispersion liquid;

[0051] (2) Dissolve 214.74mg of manganese nitrate (1.2mmol), 2.5g of urea (41.63mmol) and 40μL of isopropyl silicate (0.13mmol) in the carbon nanotube dispersion obtained in step (1), stir evenly, and refill Put it into a 100 mL stainless steel reaction kettle lined with polytetrafluoroethylene, place it in a dry box, and conduct a hydrothermal reaction at 160°C for 4 hours, then cool it down to room temperature naturally, filter, and wash with anhydrous methanol and deionized water respectively. The precipitate was washed twice successively, and then freeze-dried at -50°C and vacuum degree of 40Pa for 36 hours to obtain a black powder;

[0052] (3) Calcinate the black powder obtained in step (2) in argon / hydrogen mixed gas (where the volume fraction of hydrogen is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com