Preparation method for high-purity spherical silica micropowder

The technology of spherical silica and spherical silicon micropowder is applied in the field of chemistry, which can solve the problems of complex synthesis process of high-purity silica sol, high energy consumption of flame furnace and high cost of outsourcing, and achieves low equipment cost, high purity and fluidity. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

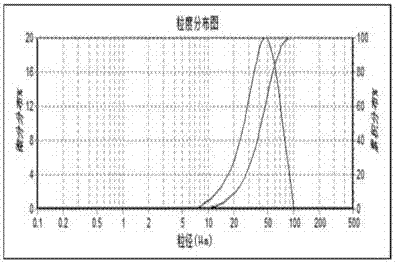

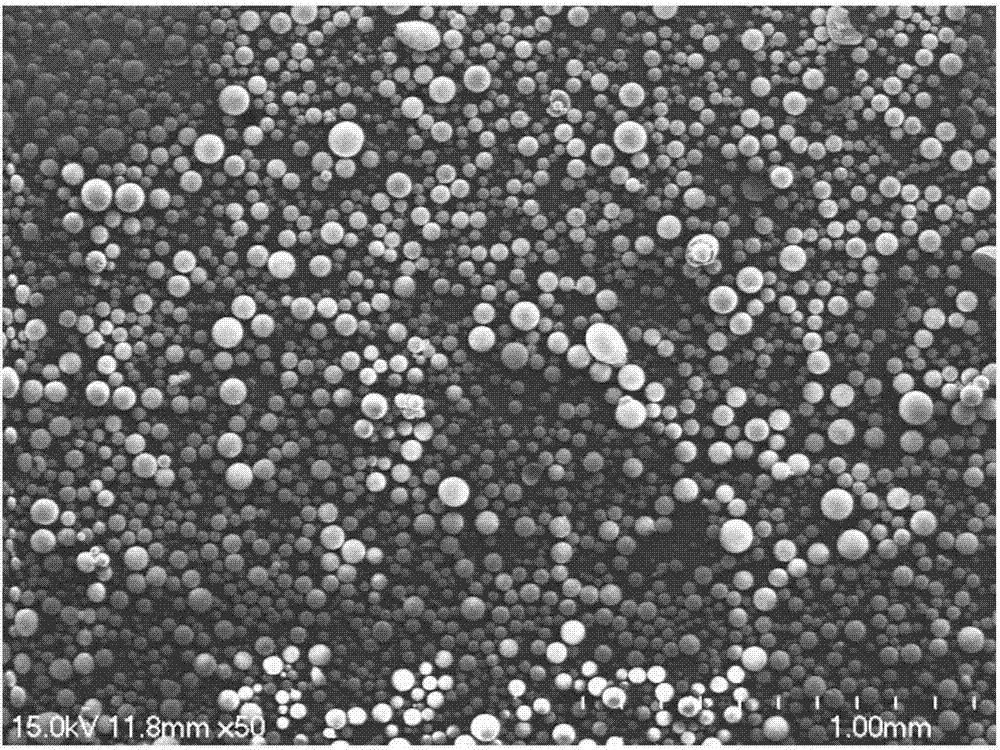

[0031] Mix the purified 100g tetramethoxysilane (TMOS), 15g pure water and a small amount of acetic acid evenly, obtain the organosilicon polymer after hydrolysis and condensation, pass 10% aqueous ammonia solution and the organosilicon polymer through the spray tower Two sets of two-fluid nozzles are used for spray atomization, the hydraulic pressure is 0.4Mpa and the air pressure is 0.6Mpa when the organosilicon polymer is atomized. The atomized silicone spherical droplets react with ammonia water to solidify and fall into the ammonia water (concentration 5%) aqueous solution at the bottom of the spray tower. After 4 hours, the silicon micropowder was separated from the solid and liquid by vacuum filtration, and the obtained filter cake was dried in an oven at 80°C for 6h, and then the powder was calcined in a high-temperature furnace at 1000°C for 1 hour to obtain high-purity spherical silica powder.

[0032] The high-purity spherical silicon micropowder prepared by the abo...

Embodiment 2

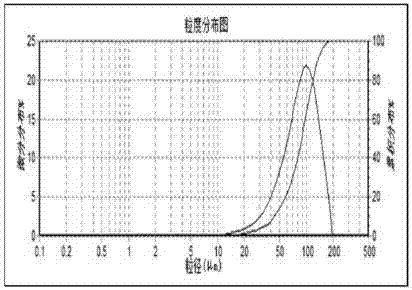

[0037] Mix the purified 100g tetraethoxysilane (TEOS), 10g pure water and a small amount of hydrochloric acid evenly, obtain the organosilicon polymer after hydrolysis and condensation, and mix 15% tetramethylammonium hydroxide aqueous solution and organic The silicone polymer is sprayed and atomized through two sets of two-fluid nozzles at the same time. The hydraulic pressure of the silicone polymer atomization is 0.5Mpa, and the air pressure is 0.4Mpa. The atomized organosilicon spherical droplet reacts with the alkaline aqueous solution and then solidifies, and falls in the tetramethylammonium hydroxide (concentration 10%) aqueous solution at the bottom of the spray tower, while the alkaline aqueous solution is self-circulated with a water pump, and then Spherical silicon micropowder is aged in tetramethylammonium hydroxide aqueous solution for 10 hours, and the solid-liquid separation of silicon micropowder is carried out by centrifugation. The obtained filter cake is drie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com