Organic controlled release fertilizer for vegetable planting which adopts attapulgite as main material

A technology of slow-release fertilizers and attapulgite, which is applied in the direction of organic fertilizers, inorganic fertilizers, and fertilizers made from biological waste, which can solve the problems that vegetable planting does not play an important role, and vegetable planting does not play a good role.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

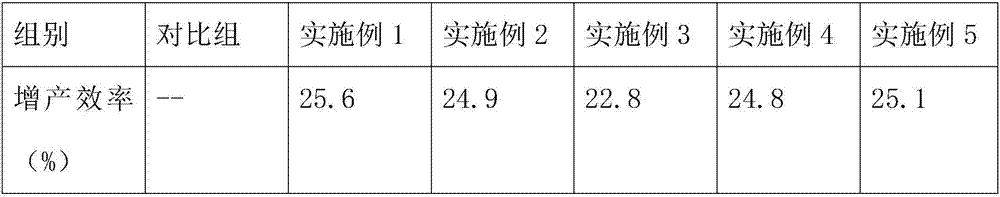

Examples

Embodiment 1

[0015]The present invention proposes an organic slow-release fertilizer with attapulgite as the main ingredient for planting vegetables. The raw materials include, by weight, 100 parts of attapulgite soil, 45 parts of chicken manure, 10 parts of swamp mud, 6.5 parts of furfural slag, and peanut cake. 6.5 parts, 1.5 parts of weathered coal, 4 parts of cotton meal, 4.5 parts of EM bacteria, 6.5 parts of urea, 2 parts of potassium chloride, 2.5 parts of ammonium nitrate, 5 parts of ammonium molybdate, 4 parts of potassium sulfate, 1.5 parts of borax, manganese sulfate 2 parts, 4 parts of zinc sulfate, 2 parts of potassium dihydrogen phosphate, 7 parts of dipotassium hydrogen phosphate, 5 parts of humic acid, 15 parts of modified slow-release agent, 20 parts of modified bentonite, 3 parts of konjac mannan, silicon 6 parts of algae, 4 parts of sepiolite.

[0016] The modified slow-release agent is prepared according to the following process: mix 6 parts of polylactic acid and 3.5 p...

Embodiment 2

[0019] The present invention proposes an organic slow-release fertilizer with attapulgite as the main ingredient for vegetable planting. The raw materials include, by weight, 80 parts of attapulgite soil, 60 parts of chicken manure, 5 parts of swamp mud, 9 parts of furfural slag, and peanut cake. 5 parts, 2 parts of weathered coal, 3 parts of cotton meal, 6 parts of EM bacteria, 5 parts of urea, 3 parts of potassium chloride, 1 part of ammonium nitrate, 6 parts of ammonium molybdate, 3 parts of potassium sulfate, 2 parts of borax, manganese sulfate 1 part, 5 parts of zinc sulfate, 1 part of potassium dihydrogen phosphate, 8 parts of dipotassium hydrogen phosphate, 4 parts of humic acid, 20 parts of modified slow-release agent, 15 parts of modified bentonite, 5 parts of konjac mannan, silicon 4 parts of algae, 6 parts of sepiolite.

[0020] The modified slow-release agent is prepared according to the following process: mix 4 parts of polylactic acid and 5 parts of dichlorometha...

Embodiment 3

[0023] A kind of organic slow-release fertilizer with attapulgite for vegetable planting proposed by the present invention as main ingredient, its raw material comprises by weight: 120 parts of attapulgite soil, 30 parts of chicken manure, 15 parts of swamp mud, 4 parts of furfural slag, peanut cake 8 parts, 1 part of weathered coal, 5 parts of cotton meal, 3 parts of EM bacteria, 8 parts of urea, 1 part of potassium chloride, 4 parts of ammonium nitrate, 4 parts of ammonium molybdate, 5 parts of potassium sulfate, 1 part of borax, manganese sulfate 3 parts, 3 parts of zinc sulfate, 3 parts of potassium dihydrogen phosphate, 6 parts of dipotassium hydrogen phosphate, 6 parts of humic acid, 10 parts of modified slow-release agent, 25 parts of modified bentonite, 1 part of konjac mannan, silicon 8 parts of algae earth, 2 parts of sepiolite.

[0024] The modified slow-release agent is prepared according to the following process: mix 8 parts of polylactic acid and 2 parts of dichl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com