A kind of tung oil-based rigid polyurethane foam and preparation method thereof

A technology of rigid polyurethane and foamed plastics, applied in the field of polyurethane materials, can solve the problems of poor product stability, high reaction temperature, increase of by-products, etc., to avoid cross-linking side reactions, broad application prospects, and good biodegradability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

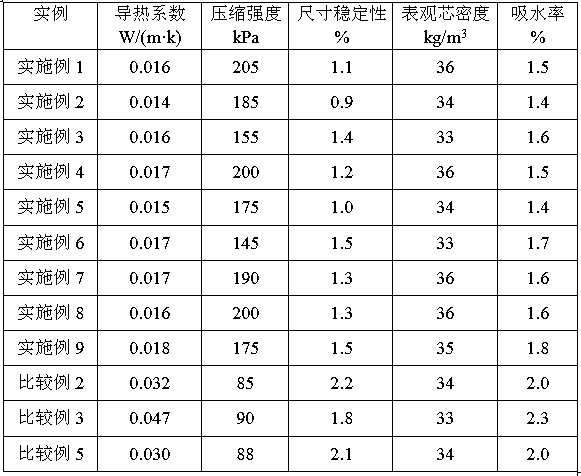

Examples

Embodiment 1

[0033] Add 500g of tung oil, 80g of formic acid (85wt% solution), 0.5g of concentrated sulfuric acid, and 150g of n-hexanoic acid into a 2000mL three-neck flask, heat up to 40°C and stir well. Then, 325g of 30wt% hydrogen peroxide solution was slowly added dropwise under vigorous stirring, and the rate of addition was controlled to keep the reaction temperature at about 50°C. After standing until the reaction system was separated, the water phase was removed, the oil phase was washed with 10wt% sodium bicarbonate aqueous solution to neutrality, and then the product was washed with hot water at 70°C for 3 times. The washed product was distilled at 2000 Pa and 80°C for 2 hours to obtain tung oil polyol.

[0034] Mix 80 g of the tung oil polyol prepared above and 14 g of diethanolamine evenly, gradually raise the temperature to 90° C. under the protection of nitrogen, and add 0.16 g of catalyst sodium methoxide, raise the temperature to 130° C. under vigorous stirring conditions,...

Embodiment 2

[0037] Add 500g of tung oil, 100g of formic acid (85wt% solution), 0.25g of concentrated sulfuric acid, and 250g of n-hexanoic acid into a 2000mL three-neck flask, heat up to 45°C and stir well. Then, 380g of 30wt% hydrogen peroxide solution was slowly added dropwise under vigorous stirring, and the dropping rate was controlled to keep the reaction temperature at about 65°C. After the reaction system was separated into layers, the water phase was removed, and the oil phase was washed with 10 wt% sodium bicarbonate aqueous solution until neutral, and then the product was washed with hot water at 70°C for 3 times. The washed product was distilled at 2000 Pa and 80°C for 2 hours to obtain tung oil polyol.

[0038] Mix 80 g of the above-prepared tung oil polyol and 16 g of diethanolamine evenly, gradually raise the temperature to 100° C. under the protection of nitrogen, add 0.16 g of catalyst sodium hydroxide, raise the temperature to 150° C. under vigorous stirring, react at con...

Embodiment 3

[0041] Add 500g of tung oil, 60g of formic acid (85wt% solution), 4g of concentrated sulfuric acid, and 120g of n-hexanoic acid into a 2000mL three-neck flask, heat up to 35°C and stir well. Then, 280g of 30wt% hydrogen peroxide solution was slowly added dropwise under vigorous stirring, and the dropping rate was controlled to keep the reaction temperature at about 45°C. After the reaction system was separated into layers, the water phase was removed, and the oil phase was washed with 10 wt% sodium bicarbonate aqueous solution until neutral, and then the product was washed with hot water at 70°C for 3 times. The washed product was distilled at 2000 Pa and 80°C for 2 hours to obtain tung oil polyol.

[0042] Mix 80 g of the tung oil polyol prepared above and 11 g of diethanolamine evenly, gradually raise the temperature to 100° C. under the protection of nitrogen, add 0.12 g of catalyst sodium ethoxide, raise the temperature to 120° C. under vigorous stirring, react at constant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com