Polylactic-acid-modified magnesium alloy medical composite material and preparation method thereof

A composite material and magnesium alloy technology, which is applied in the field of polylactic acid modified magnesium alloy medical composite material and polylactic acid modified magnesium alloy medical composite material, can solve the problem that the corrosion resistance and biocompatibility cannot be taken into account, and the risk is difficult to control. , the effect is not ideal and other problems, to achieve the effect of good cell adhesion and proliferation promotion, improved corrosion resistance, good biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

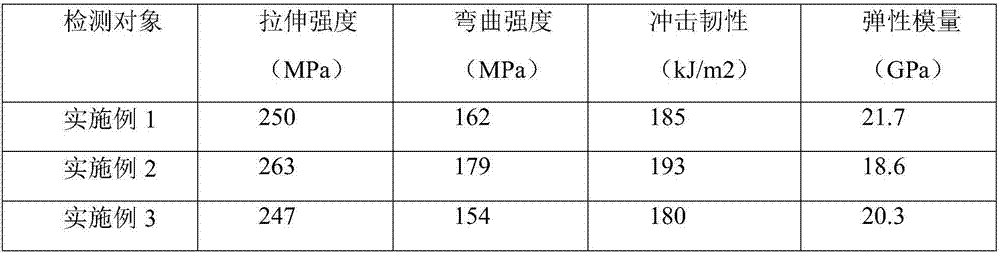

Examples

Embodiment 1

[0041] The preparation method of the polylactic acid modified magnesium alloy medical composite material of the present embodiment comprises the following steps:

[0042] 1) Take a magnesium alloy substrate with a thickness of 2.0 mm, and carry out micro-arc oxidation treatment on the surface of the magnesium alloy substrate by using a double electrolyte system of phosphate and silicate. The micro-arc oxidation treatment is a constant current treatment, and the current density is 6A / dm 2 , the power frequency is 600Hz, the duty cycle is 10%, and the treatment time is 6min; after the micro-arc oxidation is completed, rinse with deionized water, dry, and then immerse in a silane coupling agent solution with a mass concentration of 2.0%. Carry out coupling treatment at 40°C for 100 minutes, take it out and air-dry to obtain a silane coupling matrix;

[0043] 2) getting chitosan to be dissolved in acetic acid aqueous solution to make mass concentration is the chitosan solution o...

Embodiment 2

[0048] The preparation method of the polylactic acid modified magnesium alloy medical composite material of the present embodiment comprises the following steps:

[0049] 1) Take a magnesium alloy substrate with a thickness of 2.0 mm, and carry out micro-arc oxidation treatment on the surface of the magnesium alloy substrate using a phosphate and silicate double electrolyte system. The micro-arc oxidation treatment is a constant current treatment, and the current density is 3A / dm 2 , the power frequency is 600Hz, the duty cycle is 10%, and the treatment time is 10min; after the micro-arc oxidation is completed, rinse with deionized water, dry, and then immerse in a silane coupling agent solution with a mass concentration of 1.0%. Carry out coupling treatment at 50°C for 80 minutes, take it out and air-dry to obtain a silane coupling matrix;

[0050] 2) dissolving chitosan in aqueous acetic acid to make a chitosan solution with a mass concentration of 30g / L, adding surfactant...

Embodiment 3

[0055] The preparation method of the polylactic acid modified magnesium alloy medical composite material of the present embodiment comprises the following steps:

[0056] 1) Take a magnesium alloy substrate with a thickness of 2.0 mm, and carry out micro-arc oxidation treatment on the surface of the magnesium alloy substrate using a phosphate and silicate double electrolyte system. The micro-arc oxidation treatment is a constant current treatment, and the current density is 4A / dm 2 , the power frequency is 600Hz, the duty cycle is 10%, and the treatment time is 4min; after the micro-arc oxidation is completed, rinse with deionized water, dry, and then immerse in a silane coupling agent solution with a mass concentration of 1.0%. Carry out coupling treatment at 45°C for 90 minutes, take it out and air-dry to obtain a silane coupling matrix;

[0057] 2) getting chitosan to be dissolved in acetic acid aqueous solution to make mass concentration is the chitosan solution of 25g / L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com