Preparation method of fibers with antibacterial, odor-resisting and far infrared functions

A far-infrared, functional technology, applied in the textile field, can solve the problems of continuous spinning difficulties, decreased yield, poor heat resistance, etc., and achieve the effects of excellent far-infrared function, good economic benefits, and excellent antibacterial effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The preparation method of the fiber with antibacterial, deodorant and far-infrared functions comprises the following steps:

[0020] A. Preparation of antibacterial masterbatch

[0021] Calculated in parts by weight, the silicate mineral-loaded metal ion antibacterial agent includes 60 parts of silicate minerals and 40 parts of metal salts containing metal ions, and the silicate minerals are a combination of montmorillonite and sepiolite, wherein m (montmorillonite Soil removal): m (sepiolite) = 8:9, add silicate minerals into the mixer, first stir at 700rpm for 9 minutes, then adjust the rotation speed to 1000rpm and continue to stir for 5 minutes, mix well; then add nitric acid Add aluminum, ferric nitrate, and calcium nitrate into the stirrer for mixing and dissolving. Stir for 6 minutes at a speed of 3000 rpm and a temperature of 82°C. Finally, adjust the speed to 500 rpm and add deionized water. The amount of deionized water added is the metal salt. 100% of the vo...

Embodiment 2

[0026] The preparation method of the fiber with antibacterial, deodorant and far-infrared functions comprises the following steps:

[0027] A. Preparation of antibacterial masterbatch

[0028] Calculated in parts by weight, the silicate mineral-loaded metal ion antibacterial agent includes 42 parts of silicate minerals and 58 parts of metal salts containing metal ions, and the silicate minerals are a combination of sepiolite and zeolite, wherein m (sepiolite) : m (zeolite)=8:3, silicate minerals are added in the stirrer, first at a rotating speed of 700rpm, stir for 10min, then adjust the rotating speed to 1200rpm and continue to stir for 10min, mix well; then add copper nitrate, zinc nitrate, Add aluminum nitrate, ferric nitrate, calcium nitrate and magnesium nitrate to the mixer for mixing and dissolving, stir for 8 minutes at a speed of 4200rpm and a temperature of 90°C, and finally adjust the speed to 800rpm, add deionized water, the amount of deionized water added It is ...

Embodiment 3

[0033] The preparation method of the fiber with antibacterial, deodorant and far-infrared functions comprises the following steps:

[0034] A. Preparation of antibacterial masterbatch

[0035] Calculated in parts by weight, the silicate mineral-loaded metal ion antibacterial agent includes 70 parts of silicate minerals and 30 parts of metal salts containing metal ions, and the silicate minerals are montmorillonite and mica combinations, wherein m (montmorillonite ): m (mica) = 8:5, add the silicate minerals into the mixer, first stir at a speed of 500rpm for 10min, then adjust the speed to 1100rpm and continue to stir for 9min, and mix well; then silver nitrate, ferric nitrate , aluminum nitrate and titanium nitrate were added to the stirrer for mixing and dissolving, stirring at a speed of 3000rpm and a temperature of 90°C for 6min, finally adjusting the speed to 1000rpm, adding deionized water, the amount of deionized water added was the amount of metal salt 130%, continue ...

PUM

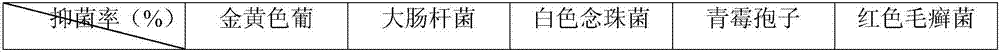

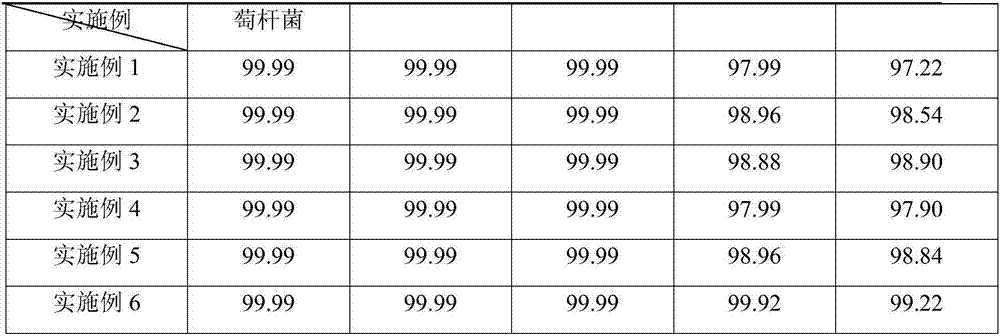

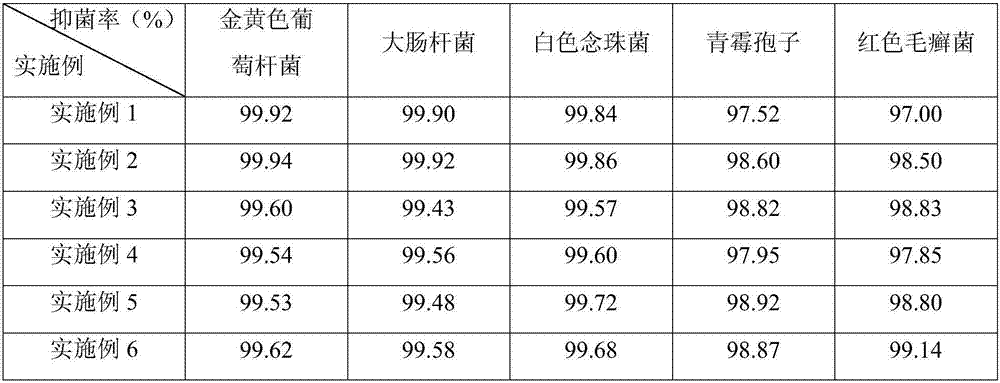

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com