Preparation method of corosolic acid as blood sugar reducing active ingredient

The technology of an active ingredient, corosolic acid, is applied in the field of preparation of corosolic acid, an active ingredient for hypoglycemia, and it can solve the problems of high loss rate of corosolic acid, high viscosity, high content of water-soluble impurities, and high total production cost. problems, to achieve the effect of simple pretreatment and posttreatment, high sample recovery rate, and less solvent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Take the dried Evodia rutaecarpa and grind it, add methanol according to the ratio of liquid to material ratio of 1:10, and conduct ultrasonic extraction for 20 minutes under the condition of ultrasonic power of 600W and 40°C for 3 times, concentrate the extract under reduced pressure, recover methanol, get the extract;

[0032] (2) The above-mentioned extract is dissolved in a sodium hydroxide solution of pH=10, and after being fully stirred evenly, it is left to stand, filtered, and insoluble matter is removed, and after the solution is neutralized by 1mol / L hydrochloric acid, an equal amount of ethyl acetate is added to extract 3 Once, collect the ethyl acetate extract, concentrate and recover the solvent, and obtain the crude extract;

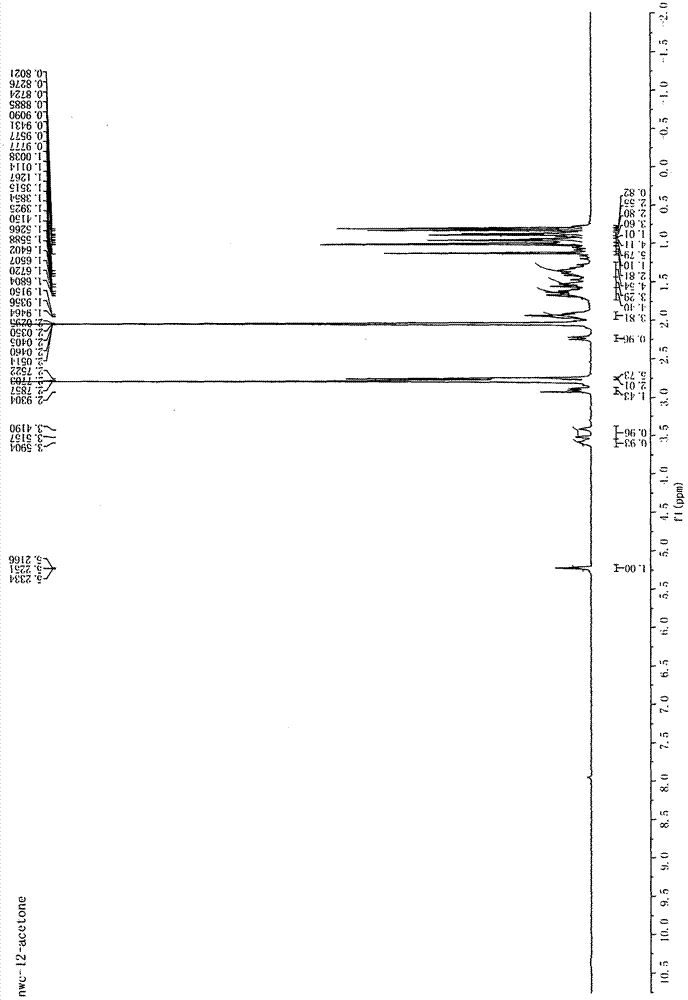

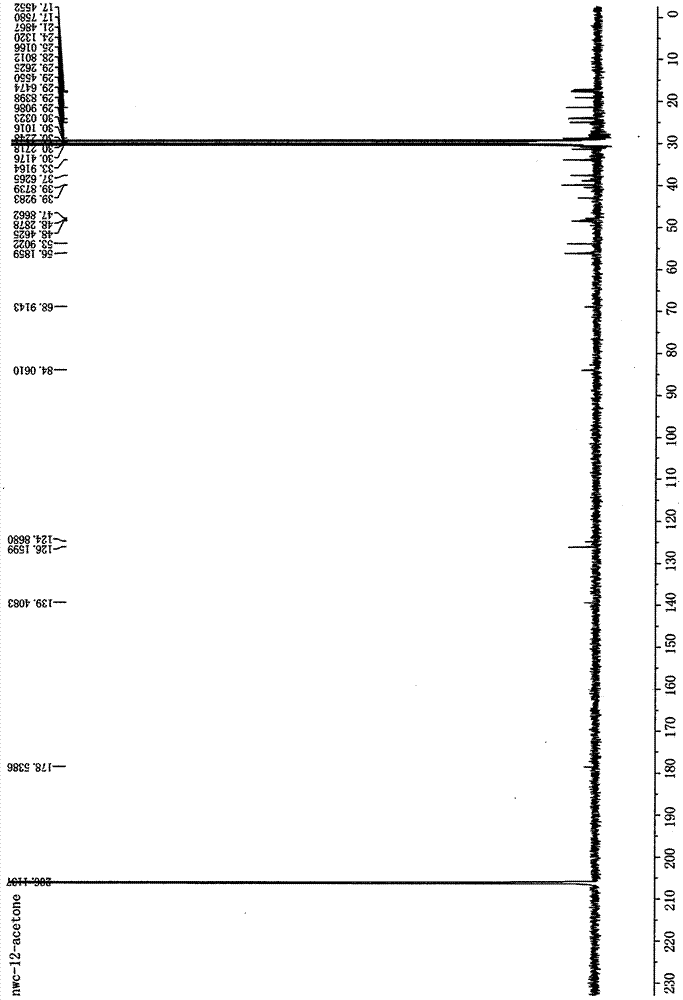

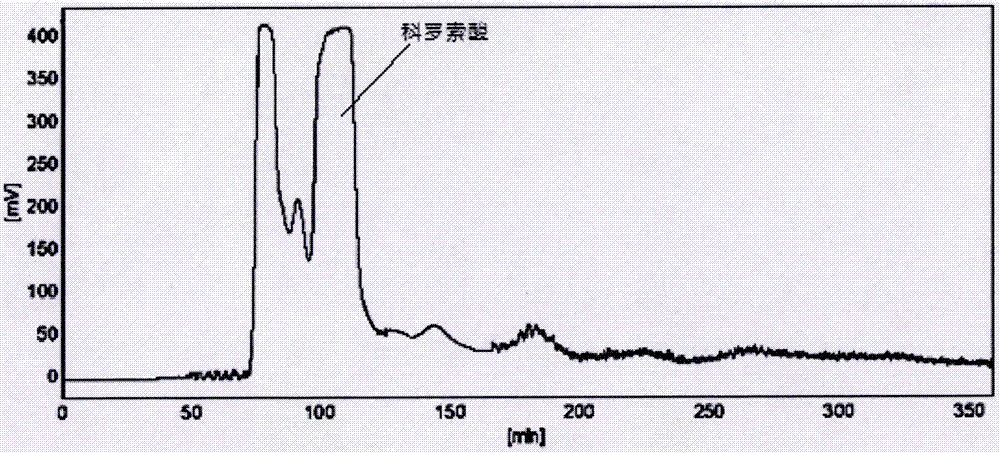

[0033] (3) The above crude extract was separated by TBE-300A high-speed countercurrent chromatography. The specific steps are: prepare a two-phase solvent system of n-hexane, ethyl acetate, methanol and water in a separatory fun...

Embodiment 2

[0035] (1) Take the dried Evodia rutaecarpa and crush it, add 80% ethanol according to the ratio of liquid to material ratio 1:8, and conduct ultrasonic extraction for 20 minutes under the conditions of ultrasonic power 600W and 40°C, extract 3 times, concentrate the extract under reduced pressure, and recover methanol to obtain extract;

[0036] (2) The above extract is dissolved in a sodium hydroxide solution with a pH of 10, stirred well, left to stand, filtered to remove insoluble matter, and the solution is neutralized by 0.5mol / L sulfuric acid, then extracted by adding an equal amount of ethyl acetate 3 times, collect the ethyl acetate extract, concentrate and recover the solvent, and obtain the crude extract;

[0037] (3) The above crude extract was separated by TBE-300A high-speed countercurrent chromatography. The specific steps are: prepare a two-phase solvent system of n-hexane, ethyl acetate, methanol, and water in a separatory funnel, mix them in a volume ratio o...

Embodiment 3

[0039] (1) Grind the dried Evodia rutaecarpa, add 60% methanol according to the ratio of liquid to material ratio of 1:12, and conduct ultrasonic extraction for 20 minutes under the condition of ultrasonic power of 600W and 40°C for 3 times, concentrate the extract under reduced pressure, and recover methanol to obtain extract;

[0040] (2) The above-mentioned extract is dissolved in a sodium hydroxide solution of pH=10, and after being fully stirred evenly, it is left to stand, filtered, and insoluble matter is removed, and after the solution is neutralized by 0.4mol / L phosphoric acid, an equal amount of ethyl acetate is added to extract 3 times, collect the ethyl acetate extract, concentrate and recover the solvent, and obtain the crude extract;

[0041] (3) The above crude extract was separated by TBE-300A high-speed countercurrent chromatography. The specific steps are: prepare a two-phase solvent system of n-hexane, ethyl acetate, methanol, and water in a separatory funnel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com