Conductive polymer dispersion and high-voltage solid-state capacitor conductive polymer emulsion

A conductive polymerization and dispersion technology, which is applied in the field of solid electrolytic capacitor preparation, can solve the problems of low temperature performance, low solid content, low viscosity, etc., and improve various performance indicators, reduce capacitor leakage, and improve withstand voltage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

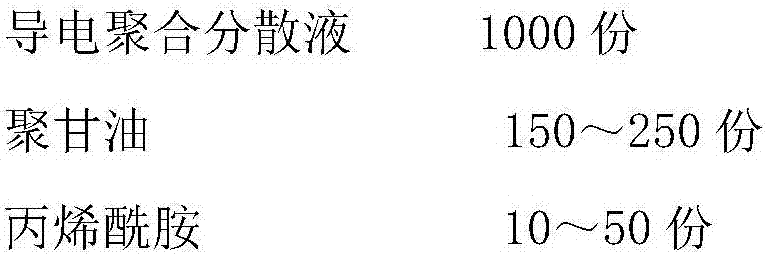

Method used

Image

Examples

Embodiment 1

[0026] Preparation of polystyrene sulfonic acid coated polyacrylate emulsion:

[0027] Add 2,000 grams of a 10% aqueous solution of sodium polystyrene sulfonate into a three-necked flask replaced with nitrogen, raise the temperature to 80°C, add 40 grams of methyl methacrylate, 10 grams of acrylamide, and 0.2 grams of emulsifier JS-20 , to form an emulsion, add 0.3 grams of ammonium persulfate, react for 4 hours, wait for it to cool to room temperature, add 50 ml of cation exchange resin, stir for 1 hour, filter and remove the exchange resin, and obtain polystyrene sulfonic acid-coated polyacrylate The emulsion is 2000mL, the measured solid content is 10%, and the particle size of the emulsion is 0.2um.

[0028] Preparation of conductive polymer dispersion with acrylate emulsion as the core:

[0029] Add 1000 grams of polyacrylic acid emulsion with a solid content of 10% to a three-necked flask replaced with nitrogen, then add 20 grams of EDOT monomer, stir and disperse to fo...

Embodiment 2

[0033] Preparation of polystyrene sulfonic acid coated polyacrylate emulsion:

[0034] Add 2,000 grams of a 10% aqueous solution of sodium polystyrene sulfonate into a three-necked flask replaced with nitrogen, raise the temperature to 80°C, add 15 grams of methyl methacrylate, 8 grams of acrylamide, and the compound emulsifier sodium ricinoleate Add 0.3 grams to form an emulsion, add 0.2 grams of ammonium persulfate, react for 4 hours, wait for it to cool to room temperature, add 50 ml of quaternary ammonium salt cation exchange resin, stir for 1 hour, filter and remove the exchange resin, and obtain polystyrene sulfonic acid The coated polyacrylate emulsion is 2000mL, the measured solid content is 8%, and the particle size of the emulsion is 0.2um.

[0035] Preparation of conductive polymer dispersion with acrylate emulsion as the core:

[0036] Add 1000 grams of polyacrylic acid emulsion with a solid content of 8% into a three-necked flask replaced with nitrogen, then add ...

Embodiment 3

[0040] Preparation of polystyrene sulfonic acid coated polyacrylate emulsion:

[0041]Add 2,000 grams of a 10% aqueous solution of sodium polystyrene sulfonate into a three-necked flask replaced with nitrogen, raise the temperature to 80°C, add 65 grams of methyl methacrylate, 12 grams of acrylamide, and the compound emulsifier sodium ricinoleate Add 0.5 grams to form an emulsion, add 0.2 grams of ammonium persulfate, react for 4 hours, wait for it to cool to room temperature, add 50 ml of quaternary ammonium salt cation exchange resin, stir for 1 hour, filter and remove the exchange resin, and obtain polystyrene sulfonic acid The coated polyacrylate emulsion is 2000mL, the measured solid content is 11%, and the particle size of the emulsion is 0.2um.

[0042] Preparation of conductive polymer dispersion with acrylate emulsion as the core:

[0043] Add 1,000 grams of polyacrylic acid emulsion with a solid content of 11% into a three-necked flask replaced with nitrogen, then a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com