Nitrogen-doped carbon nanocomposite as well as preparation method and use thereof

A technology of nanocomposite materials and carbon nanomaterials, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve problems such as electrolyte channel blockage, and achieve improved specific capacitance, good fluidity, and high pseudocapacitance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

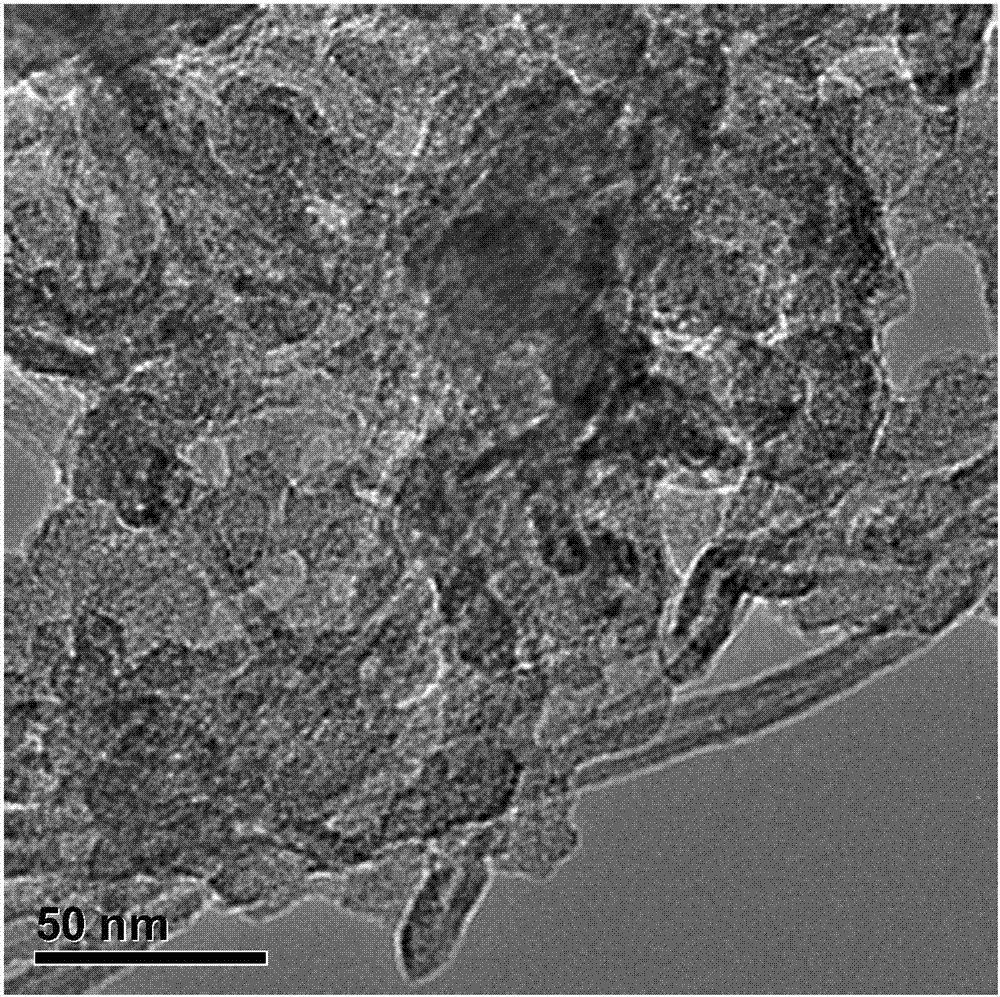

[0061] Add 1 g of terephthalonitrile (p-DCB) and 0.2 g of multi-walled carbon nanotubes into 100 mL of ethanol, evaporate the ethanol solvent under stirring at 78 ° C to obtain a composite of the two, and then mix the composite with anhydrous Zinc chloride 5.32g was mixed uniformly, and transferred to a tube furnace, reacted at 600°C for 10 hours, and after cooling to room temperature naturally, the obtained carbon nanocomposite was washed with 5wt% hydrochloric acid, pure water, tetrahydrofuran successively, and then Put it into an oven, and dry it at 120° C. for 10 hours to obtain a nitrogen-doped carbon nanocomposite material.

[0062] Performance Characterization:

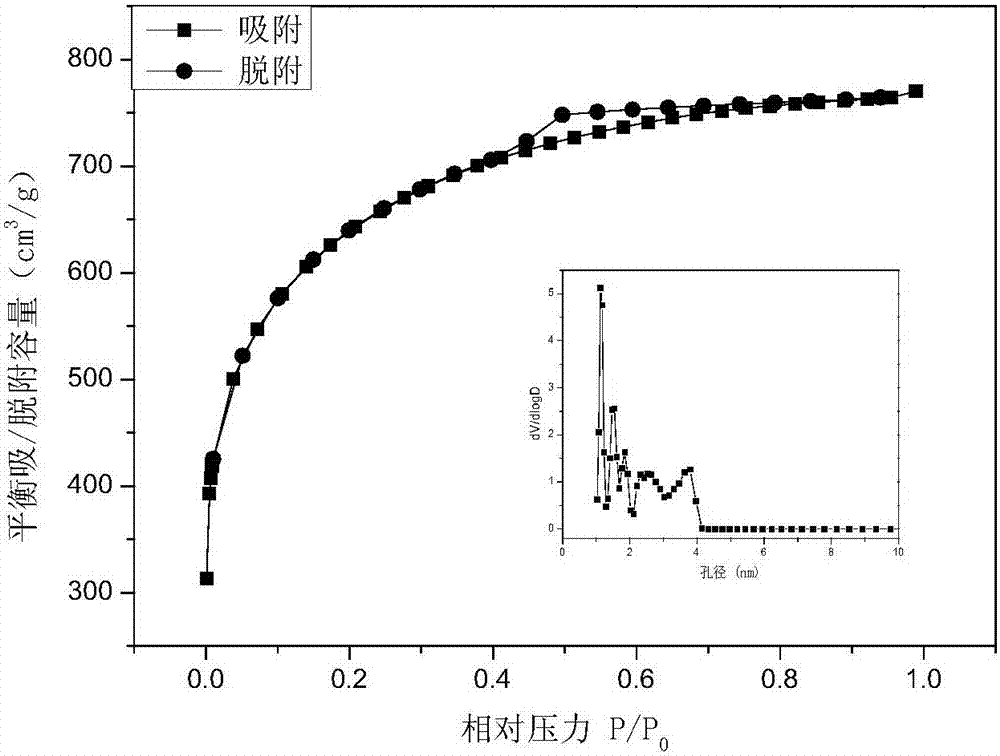

[0063] The specific surface and pore size distribution of the nitrogen-doped carbon nanocomposite material are measured by the isothermal adsorption-desorption method of nitrogen at 77K, the specific surface area is calculated by the BET method, and the pore size distribution is calculated by the DFT method. T...

Embodiment 2

[0070] Add 1 g of isophthalonitrile (m-DCB) and 0.2 g of multi-walled carbon nanotubes into 100 mL of ethanol, evaporate the ethanol solvent under stirring at 78 ° C to obtain a composite of the two, and then mix the composite with anhydrous Zinc chloride 5.32g was mixed uniformly, and transferred to a tube furnace, reacted at 600°C for 10 hours, and after cooling to room temperature naturally, the obtained carbon nanocomposite was washed with 5wt% hydrochloric acid, pure water, tetrahydrofuran successively, and then Put it into an oven, and dry it at 120° C. for 10 hours to obtain a nitrogen-doped carbon nanocomposite material.

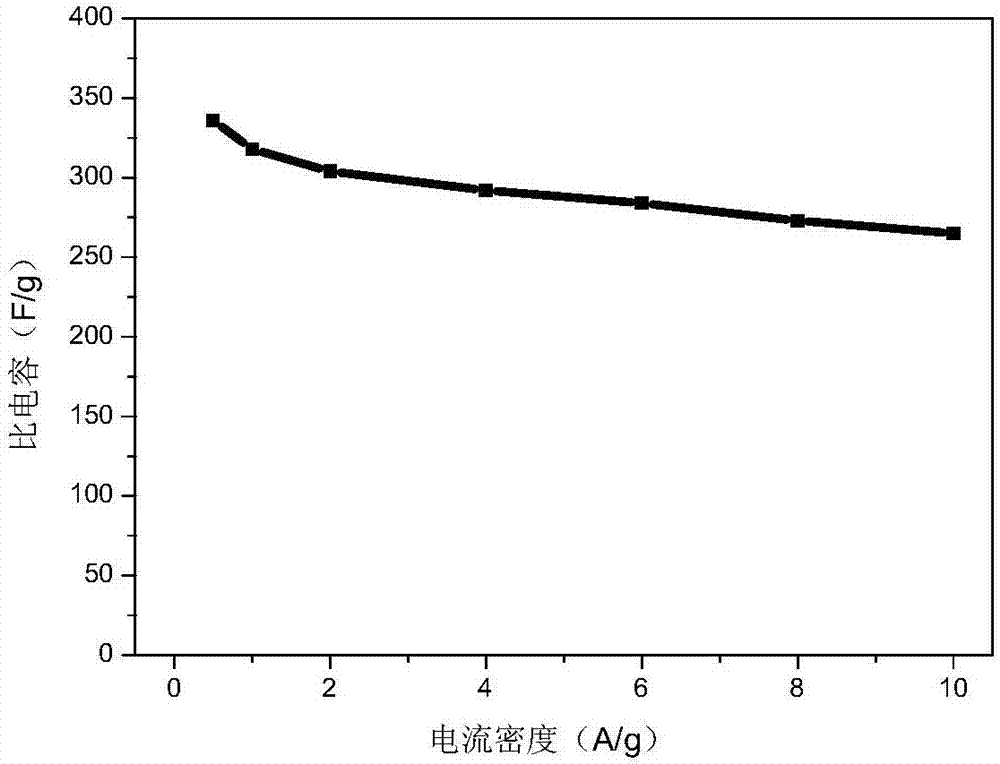

[0071] The nitrogen content of the composite material is 10%, and at a current density of 0.5A / g, the specific capacitance is 332F / g; at a current density of 10A / g, the specific capacitance is 267F / g; at a current density of 10A / g After 10,000 cycles, the specific capacity has not decayed.

Embodiment 3

[0073] Add 1 g of phthalonitrile (o-DCB) and 0.2 g of multi-walled carbon nanotubes into 100 mL of ethanol, evaporate the ethanol solvent under stirring at 78 ° C to obtain a composite of the two, and then mix the composite with anhydrous Zinc chloride 5.32g was mixed uniformly, and transferred to a tube furnace, reacted at 600°C for 10 hours, and after cooling to room temperature naturally, the obtained carbon nanocomposite was washed with 5wt% hydrochloric acid, pure water, tetrahydrofuran successively, and then Put it into an oven, and dry it at 120° C. for 10 hours to obtain a nitrogen-doped carbon nanocomposite material.

[0074] The nitrogen content of the composite material is 10%, and at a current density of 0.5A / g, the specific capacitance is 335F / g; at a current density of 10A / g, the specific capacitance is 263F / g; at a current density of 10A / g After 10,000 cycles, the specific capacity has not decayed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com