Method for preparing anode materials lithium nickel manganese oxide with micron-size truncated octahedral structures

A technology of lithium nickel manganese oxide and positive electrode materials, which is applied in the direction of structural parts, chemical instruments and methods, battery electrodes, etc., can solve the problem of extending the migration path of lithium ions and electrons in size, shortening the migration path of Li ions and electrons, and aggravating the relationship between electrodes and electrodes. Solve problems such as electrolyte side reactions, achieve excellent cycle performance and rate performance, reduce insertion/extraction resistance, and improve rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] The present invention is a preparation method of lithium nickel manganese oxide, a positive electrode material with a micron-sized truncated octahedral structure, the steps of which are as follows:

[0014] (1) At room temperature, with a molar ratio of 2.1:1:3, dissolve lithium salt, nickel salt and manganese salt in anhydrous ethanol solution, in which the molar concentration of manganese ions is 0.2~1.2 mol / L, and ultrasonically stir to obtain Clear and transparent solution;

[0015] (2) Add graphite to the above solution, the molar amount of graphite is 0.04 times that of manganese ions, and continue ultrasonic stirring for 1~6 h;

[0016] (3) Heat the obtained solution at 60-80 ℃ and evaporate to dryness, recover the solvent and obtain a black paste; dry the paste at 60-100 ℃ for 6-15 h;

[0017] (3) Ball mill the dried paste for 1-5 h, and then calcinate at 700-900 °C for 8-15 h to obtain lithium nickel manganese oxide with micron truncated octahedral structure. ...

Embodiment 1

[0023] (a) Dissolve 0.21 mol of lithium acetate, 0.1 mol of nickel acetate, and 0.3 mol of manganese acetate in 1 L of absolute ethanol solution;

[0024] (b) Add 0.012 mol of graphite and continue ultrasonic stirring for 3 h;

[0025] (c) The resulting solution was heated at 75 °C to recover the absolute ethanol solvent and obtain a black paste. The resulting paste was then dried in an oven at 75 °C for 10 h;

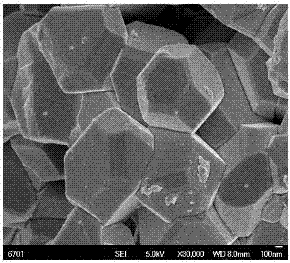

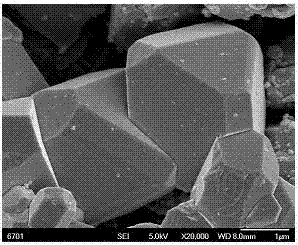

[0026] (d) After drying, ball mill for 2 h to ensure the uniform distribution of graphite as far as possible, and place the obtained powder in a muffle furnace for calcination at 850 °C for 10 h to obtain the following: figure 1 Lithium nickel manganese oxide material with truncated octahedral structure shown.

Embodiment 2

[0028] (a) Dissolve 0.21 mol lithium acetate, 0.1 mol nickel acetate, and 0.3 mol manganese acetate in 0.5 L absolute ethanol solution;

[0029] (b) Add 0.012 mol of graphite and continue ultrasonic stirring for 3 h;

[0030] (c) The resulting solution was heated at 75 °C to recover the absolute ethanol solvent and obtain a black paste. The resulting paste was then dried in an oven at 75 °C for 10 h;

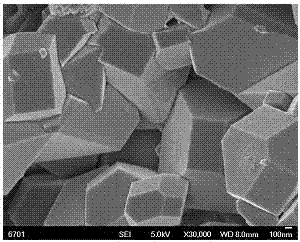

[0031] (d) The dried material was ball milled for 2 h to ensure the uniform distribution of graphite, and the obtained powder was calcined in a muffle furnace at 850 °C for 10 h to obtain the following figure 2 Lithium nickel manganese oxide material with truncated octahedral structure shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com