Preparation method of pesticide nanocapsules

A technology of nanocapsules and pesticides, applied in the field of pesticides, can solve the problems of dust drift, uneven particle size distribution, and droplet rolling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

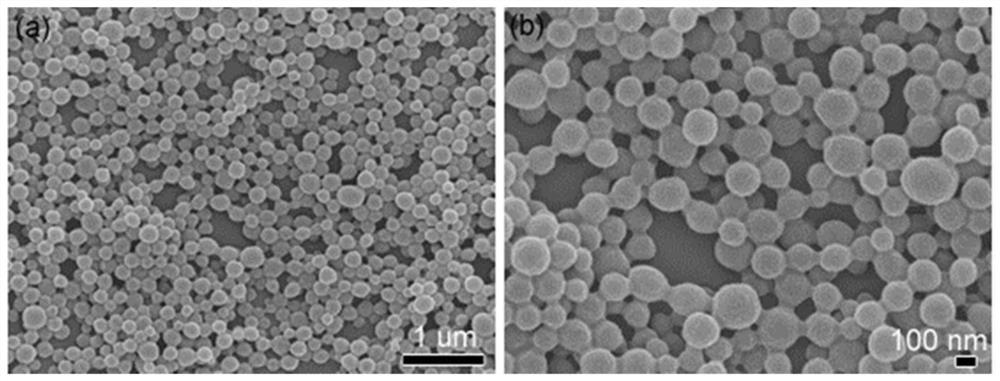

Image

Examples

Embodiment 1

[0132] The preparation of embodiment 1 pesticide nanocapsule powder 1

[0133] Disperse 0.8g of the active ingredient A thiamethoxam in the inner phase in 20ml of water to obtain the inner water phase, dissolve 2g of the active ingredient B emamectin benzoate in the outer phase in 50ml of the organic solvent dichloromethane, add 2g of capsules Wall material cellulose, to obtain the oil phase, using an ultrasonic pulverizer to drop the inner water phase into the oil phase at 585W, ultrasonic emulsification for 15min, to obtain a W / O emulsion; 2g emulsifying dispersant (1g polyvinyl alcohol and 1g ten Sodium dialkyl sulfonate) was dissolved in 150ml water to obtain the external water phase, and the W / O type emulsion obtained was added dropwise to the external water phase under 28000rmp using a high-pressure shearing machine, and sheared and emulsified for 15min to obtain the W / O / W-type primary emulsion, wherein the droplet size of the primary emulsion is 300nm.

[0134] The ab...

Embodiment 2

[0137] The preparation of embodiment 2 pesticide nanocapsules aqueous suspension 2

[0138] Disperse 0.8g of the active ingredient A thiamethoxam in the inner phase in 20ml of water to obtain the inner water phase, dissolve 2g of the active ingredient B emamectin benzoate in the outer phase in 50ml of the organic solvent dichloromethane, add 2g of capsules Wall material cellulose, to obtain the oil phase, using an ultrasonic pulverizer to drop the inner water phase into the oil phase at 585W, ultrasonic emulsification for 15min, to obtain a W / O emulsion; 2g emulsifying dispersant (1g polyvinyl alcohol and 1g ten Sodium dialkyl sulfonate) was dissolved in 150ml water to obtain the external water phase, and the W / O type emulsion obtained was added dropwise to the external water phase under 28000rmp using a high-pressure shearing machine, and sheared and emulsified for 15min to obtain the W / O / W-type primary emulsion, wherein the droplet size of the primary emulsion is 300nm.

...

Embodiment 3

[0142] The preparation of embodiment 3 pesticide nanocapsule powder 3

[0143] 0.5g internal phase active ingredient A emamectin benzoate is dispersed in 50ml water to obtain the inner water phase, and 2g external phase active ingredient B emamectin benzoate is dissolved in 100ml organic solvent two In the methyl chloride, add 3g polylactic acid, the capsule wall material, to obtain the oil phase, and use an ultrasonic pulverizer to add the inner water phase to the oil phase dropwise at 585W, and ultrasonically emulsify for 15min to obtain a W / O emulsion; emulsify and disperse 3.5g Agent (1g polyvinyl alcohol, 1.5g Nongru 600 and 1g Nongru 700) was dissolved in 300ml water to obtain the outer water phase, and the W / O type emulsion obtained was added dropwise to the outer water phase at 28000rmp using a high pressure shearing machine , and shear emulsified for 15 minutes to obtain a W / O / W type primary emulsion, wherein the droplet diameter of the primary emulsion is 300nm.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com