Preparation method of ethyl lauroyl arginate hydrochloride

A technology of lauroyl arginine ethyl ester hydrochloride and arginine hydrochloride, which is applied to the preparation of organic compounds, organic chemical methods, skin care preparations, etc., and can solve the problem of low content and purity and water removal Low efficiency, poor crystal form and other problems, to achieve the effect of high product purity, good crystallization effect, and easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

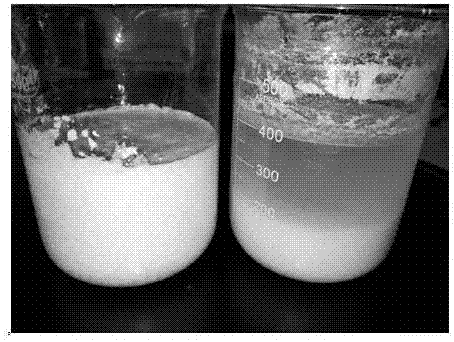

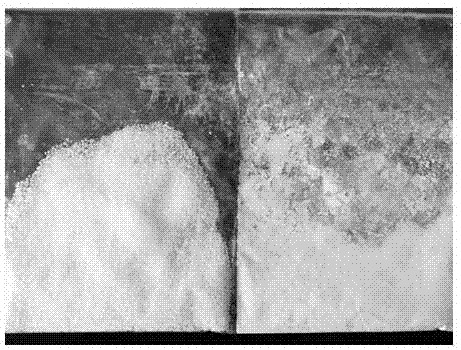

Embodiment 1

[0038] 60kg of water and 60kg of acetone were sequentially pumped into the 200L reactor, 21kg of arginine hydrochloride was added into the reactor, stirred and dissolved, the temperature was lowered to 5°C, and the pH value was adjusted to 10 with 20wt% sodium hydroxide aqueous solution. Add 21.9kg of lauroyl chloride dropwise to the system, and at the same time add 20wt% sodium hydroxide aqueous solution dropwise to keep the pH at 10 and the temperature at 5°C. After the addition of lauroyl chloride is completed, stir for 2 hours and use 6mol / L Adjust the pH to 7 with hydrochloric acid, centrifuge, and dry to obtain lauroyl arginine. Put the obtained lauroyl arginine into a 200L reactor, add 100kg of ethanol, 11.9kg of thionyl chloride, reflux for 5 hours, evaporate the ethanol under reduced pressure to obtain a crude product, add 150kg of ethyl acetate to the reactor, and add 5wt% of 30kg of sodium bicarbonate aqueous solution, stirred evenly, left to stand for stratificatio...

Embodiment 2

[0040] Pump 60kg of water and 70kg of ethyl acetate into the 200L reaction kettle in sequence, add 21kg of arginine hydrochloride into the reaction kettle, stir and dissolve, cool down to 10°C, and use 20wt% sodium carbonate aqueous solution to adjust the pH value to 9 , add 21.9kg of lauroyl chloride dropwise to the system, and at the same time add dropwise 20wt% sodium carbonate aqueous solution to keep the pH at 9 and the temperature at 10°C. After the addition of lauroyl chloride is completed, stir for 5 hours and use 6mol / L Adjust the pH to 5 with hydrochloric acid, centrifuge, and dry to obtain lauroyl arginine. Put the obtained lauroyl arginine into a 200L reactor, add 80kg of ethanol, 13kg of thionyl chloride, react at 30°C for 9 hours, evaporate the ethanol under reduced pressure to obtain a crude product, add 150kg of butyl acetate into the reactor, and add 10wt% 30kg of aqueous sodium carbonate solution, stirred evenly, allowed to stand for stratification, discarded...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com