Luminous textile fabric preparation method based on laser annealing technology

A technology for textile fabrics and laser annealing, which is applied in the fields of luminescent materials, textiles and papermaking, chemical instruments and methods, etc., can solve the problems of low processing efficiency, low crystallization performance and high processing temperature, and achieves simple and convenient process and strong operability. , good lighting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

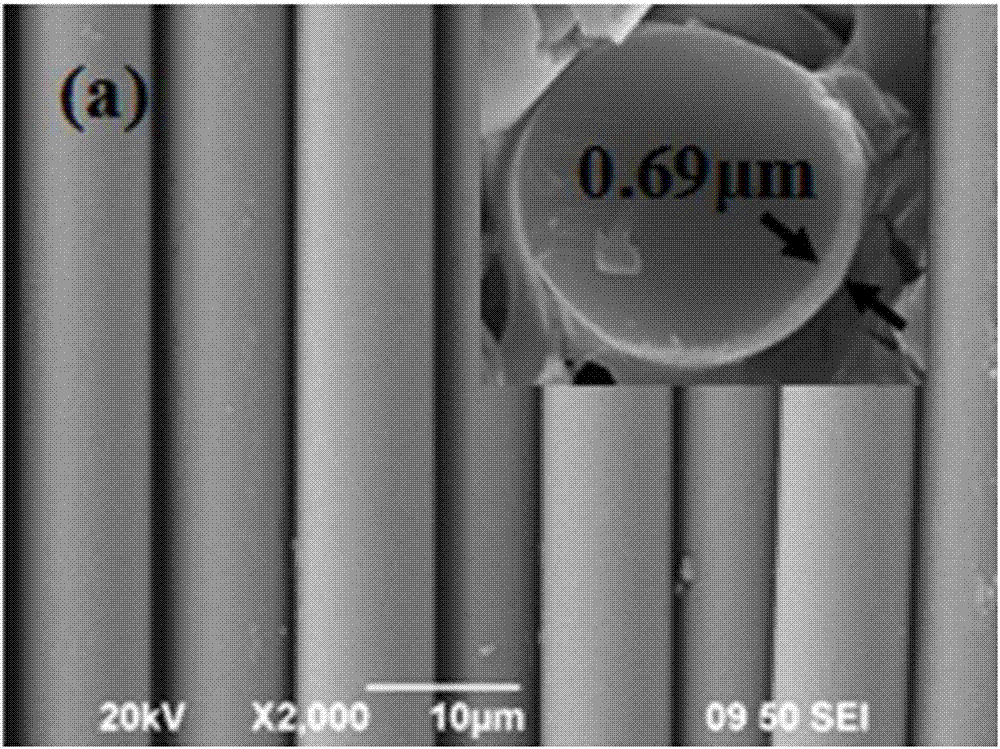

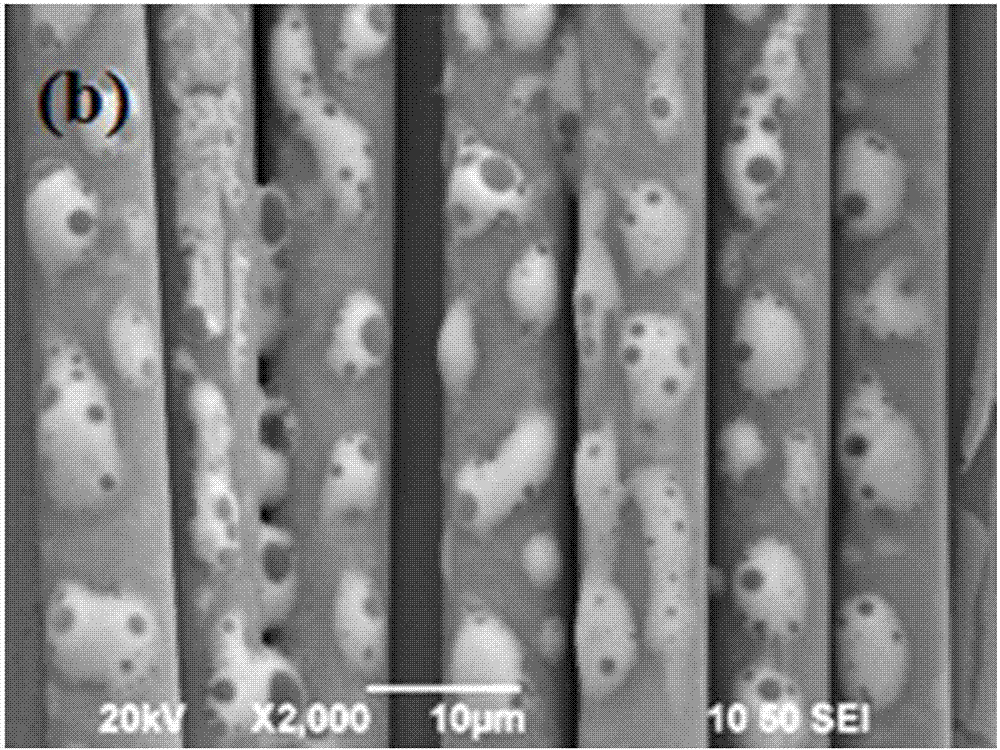

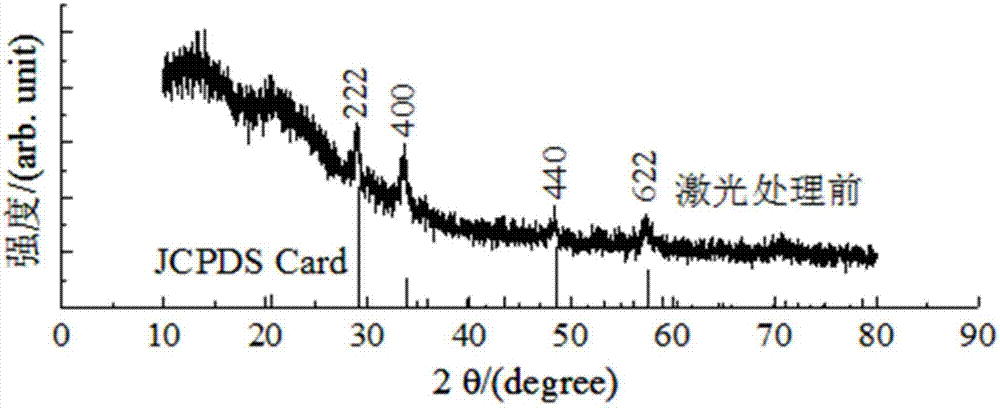

[0033] The preparation method of the luminous textile fabric of the embodiment of the present invention comprises the following steps:

[0034] (1) Preparation of evaporation targets

[0035] Yttrium oxide red luminescent powder doped with trivalent europium ions (Y 1.80 o 3 :Eu 0.20 ) was poured into a mold with a diameter of Φ30mm, and pressed with a 3855 American CARVER manual standard hydraulic tablet press under a static pressure of 10 tons for 5 minutes to obtain a circular cake-shaped evaporation target material with a thickness of about 2mm. Put the compressed evaporation target in an oven at 100°C for 24 hours to dry to remove moisture adsorbed in the air, and then put it into a water-cooled crucible in the vacuum chamber of the coating equipment.

[0036] The vapor deposition target prepared by the above method does not need to be annealed and sintered due to sufficient pressing force, and has simple process, convenient operation and high efficiency.

[0037] (2)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com