Preparation method of lithium lanthanum zirconium oxide nanometer fiber, preparation method of composite film and solid battery application

A lithium-lanthanum-zirconium-oxygen nanofiber and lithium-lanthanum-zirconium-oxygen fiber technology, applied in the application of solid-state lithium batteries, lithium-lanthanum-zirconium-oxygen nanofibers, the field of composite film preparation, can solve easy clogging, loss of battery capacity and cycle life, etc. problems, to avoid clogging, improve high temperature performance and safety, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

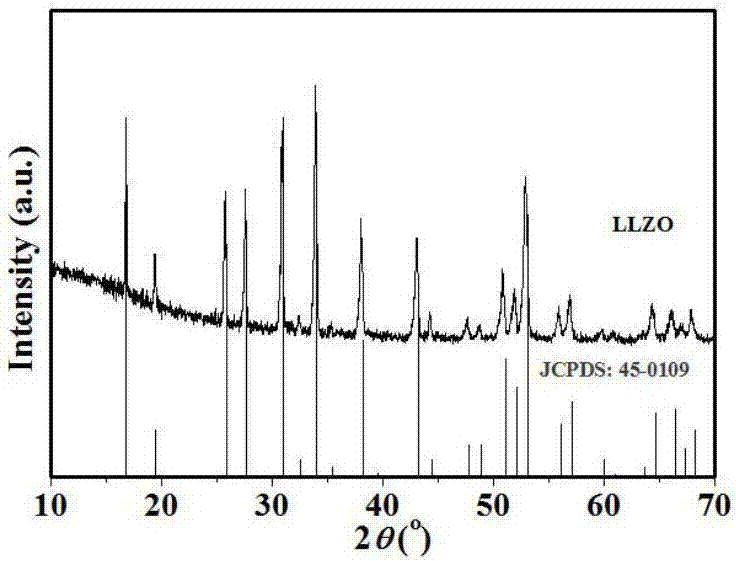

[0041] Example 1: Lithium Lanthanum Zirconium Oxygen Nanofiber-Polyethylene Oxide Composite Film Applied to Solid State Batteries

[0042] (1) Dissolve 1.323g of lithium nitrate, 3.89g of lanthanum nitrate, and 1.38g of zirconyl nitrate in a mixed solution of 25mL of deionized water, 5mL of acetic acid, and 15mL of isopropanol, and stir at room temperature for 5 hours to obtain a solution containing 0.03mol Li 7 La 3 Zr 2 o 12 6mL of the precursor sol solution was taken for later use; polyvinylpyrrolidone (PVP) was dissolved in 4ml of acetic acid, and stirred to obtain a uniform mixed solution, wherein the mass percentage of PVP in acetic acid was 10%. The two solutions are fully mixed to obtain 10ml of spinning solution;

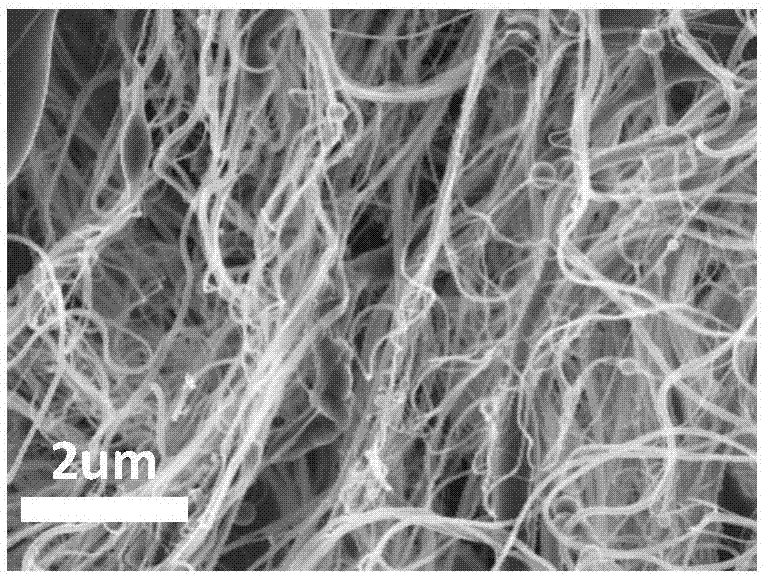

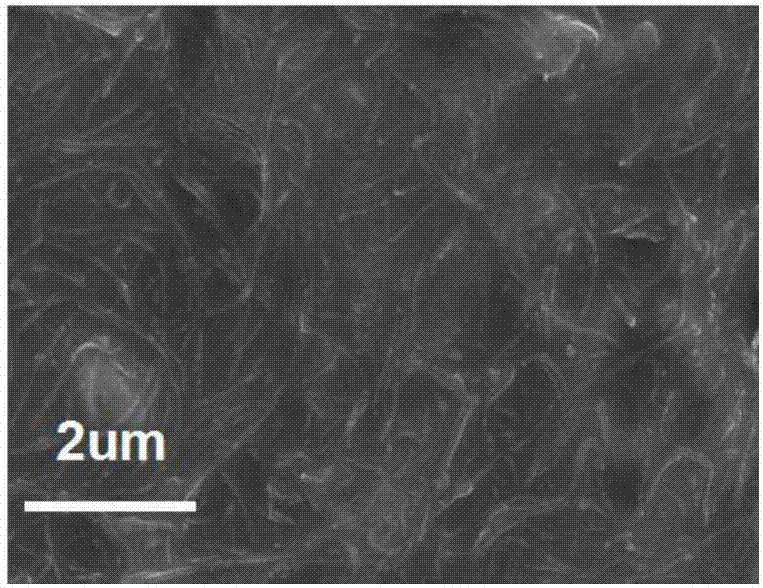

[0043] (2) Transfer the spinning precursor solution to a 10mL syringe, install it in the air-jet spinning device, and the airflow pressure is 4000kPa, and a uniform white fiber film can be collected quickly and efficiently on the iron wire receiving plat...

Embodiment 2

[0051] Example 2: Lithium Lanthanum Zirconium Oxygen Nanofiber-Polyethylene Carbonate Composite Film Applied to Solid State Batteries

[0052] (1) Dissolve 1.323g of lithium nitrate, 3.89g of lanthanum nitrate, and 1.38g of zirconyl nitrate in a mixed solution of 25mL of deionized water, 5mL of acetic acid, and 15mL of isopropanol, and stir at room temperature for 5 hours to obtain a solution containing 0.03mol Li 7 La 3 Zr 2 o 12 6mL of the precursor sol solution was taken for later use; polyvinylpyrrolidone (PVP) was dissolved in 4ml of acetic acid, and stirred to obtain a uniform mixed solution, wherein the mass percentage of PVP in acetic acid was 10%. The two solutions are fully mixed to obtain 10ml of spinning solution;

[0053] (2) Transfer the spinning precursor solution to a 10mL syringe, install it in the air-jet spinning device, and the airflow pressure is 4000kPa, and a uniform white fiber film can be collected quickly and efficiently on the iron wire receiving ...

Embodiment 3

[0061] Example 3: Al-doped lithium lanthanum zirconium oxide nanofiber-polypropylene carbonate composite film applied to solid-state batteries

[0062] (1) 1.323g of lithium nitrate, 3.89g of lanthanum nitrate, 1.38g of zirconium oxynitrate and 0.22g of aluminum nitrate were dissolved in a mixed solution of 25mL of deionized water, 5mL of acetic acid, and 15mL of isopropanol, and stirred at room temperature for 5 hours, Obtained containing 0.03molLi 6.4 La 3 Zr 2 Al 0.2 o 12 6mL of the precursor sol solution was taken for later use; polyvinylpyrrolidone (PVP) was dissolved in 4ml of acetic acid, and stirred to obtain a uniform mixed solution, wherein the mass percentage of PVP in acetic acid was 10%. The two solutions are fully mixed to obtain 10ml of spinning solution;

[0063] (2) Transfer the spinning precursor solution to a 10mL syringe, install it in the air-jet spinning device, and the airflow pressure is 4000kPa, and a uniform white fiber film can be collected quic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com