Room temperature solid phase preparation method for cuprous oxide/copper oxide nanocomposite

A technology of nanocomposites and cuprous oxide, applied in the direction of copper oxide/copper hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of complex operation, cumbersome steps, large solvent consumption, etc., and achieve high product yield and high The effect of catalytic activity and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] At room temperature, mix 0.5g cuprous chloride and 0.4g sodium hydroxide, grind them for 30 minutes to make them undergo solid-phase chemical reaction, wash the products with ammonia water, water and ethanol respectively, and dry them with air at 60 degrees for 6 hours Get Cu 2 O / CuO nanocomposites.

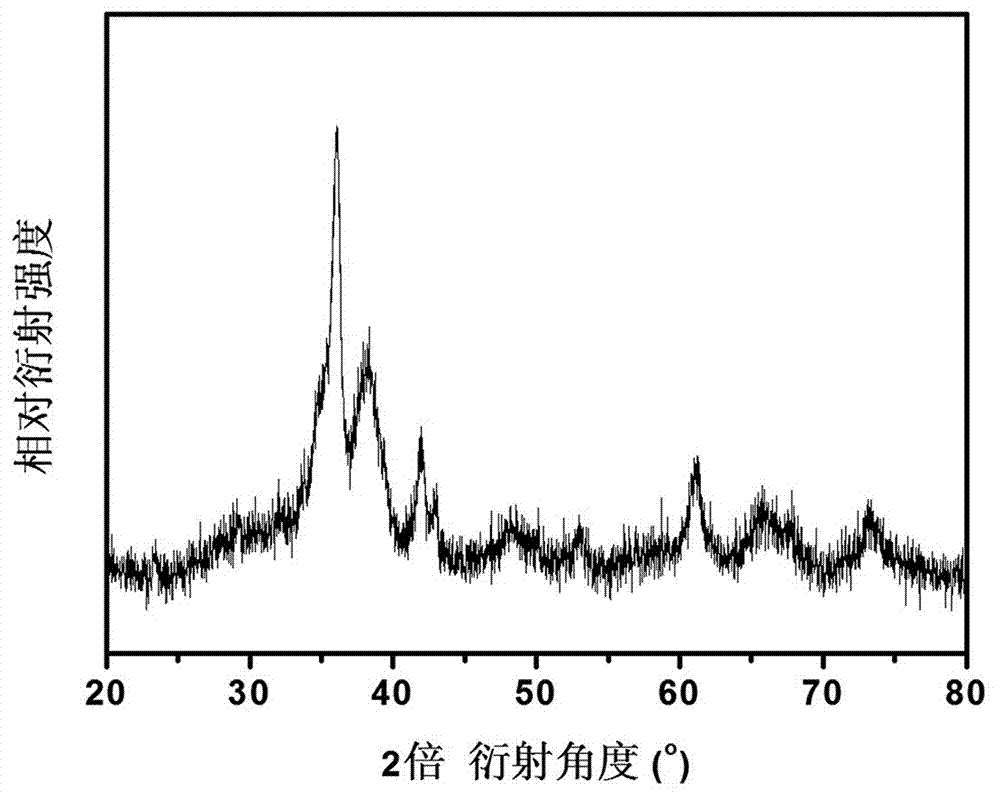

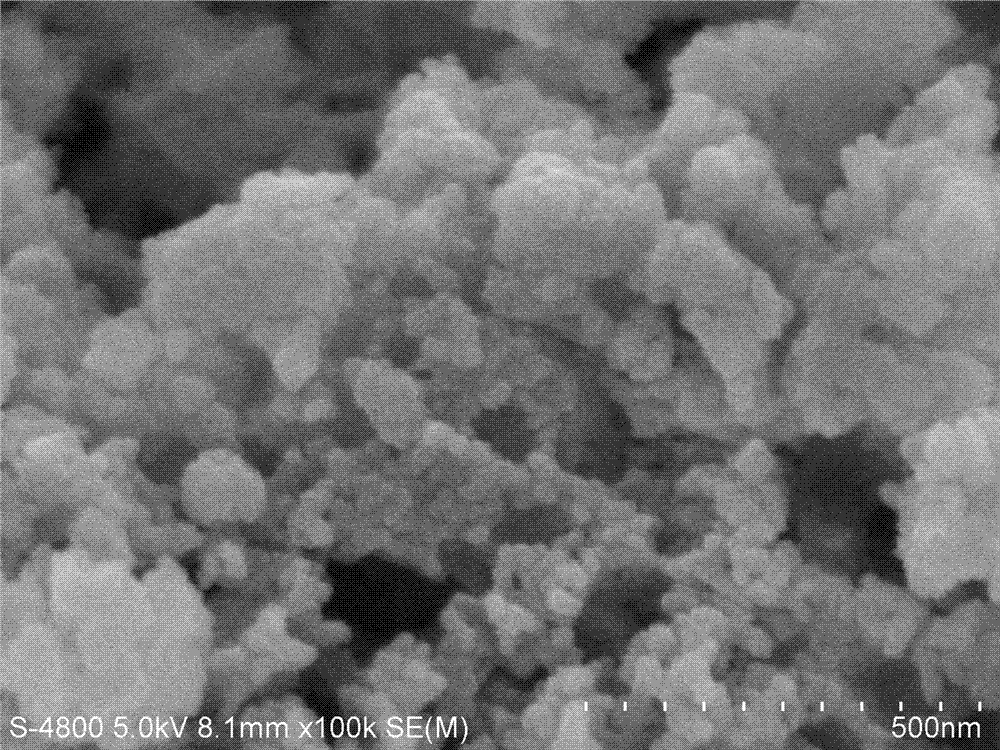

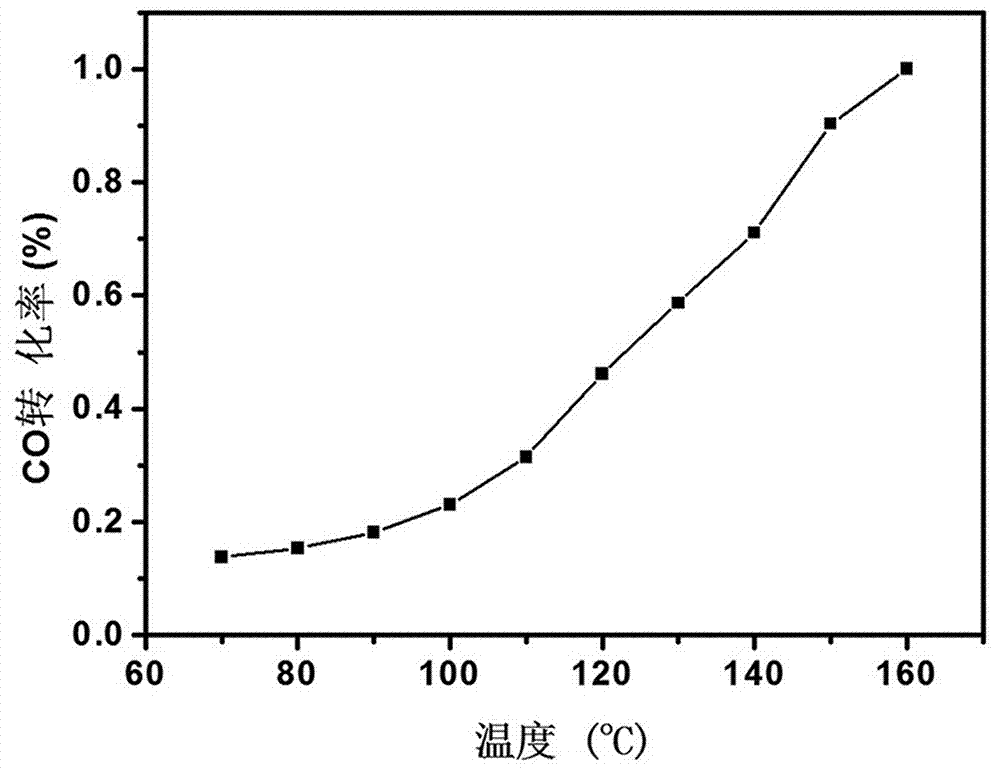

[0016] By the powder X-ray diffraction pattern of product ( figure 1 ) It can be seen that the prepared product contains Cu 2 O, CuO; by scanning electron microscope pictures ( figure 2 ) It can be seen that the product is an irregular spherical particle of 20-50nm; Cu 2 O / CuO nanocomposites can completely convert carbon monoxide into carbon dioxide at 160 degrees ( image 3 ).

Embodiment 2

[0018] At room temperature, mix 0.5g of cuprous chloride, 0.4g of sodium hydroxide, and 0.3g of urea, and grind them for 50 minutes to cause a solid-phase chemical reaction. The products are washed with ammonia water, water, and ethanol, and blown at 80 degrees Cu was obtained after drying for 6 hours 2 O / CuO nanocomposites.

Embodiment 3

[0020] At room temperature, mix 0.5g of cuprous chloride and 0.28g of potassium hydroxide, grind them for 30 minutes to cause a solid-phase chemical reaction, wash the products with ammonia water, water, and ethanol, and dry them with air at 60 degrees for 6 hours get nano Cu 2 O.

[0021] By the powder X-ray diffraction pattern of product ( Figure 4 ) It can be seen that the prepared product is Cu2O; from the scanning electron microscope picture ( Figure 5 ) It can be seen that the product is an irregular spherical particle of about 50nm; nano-Cu 2 O can completely convert carbon monoxide into carbon dioxide at 140 degrees ( Image 6 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com