An equipment and forming method for free-rolling and bending of super-hybrid composite laminates

A composite layer and ultra-hybrid technology, applied in the direction of metal processing, etc., can solve the problems that the metal layer and the composite material layer cannot be deformed together, cannot guarantee the forming accuracy of the component, cannot guarantee the constant pressure of the blank, etc., and achieve strong designability, Improved designability and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] In the first step, the 2024 aluminum alloy coil with a thickness of 0.3 mm is subjected to degreasing, alkali cleaning, pickling and phosphoric acid anodizing treatment;

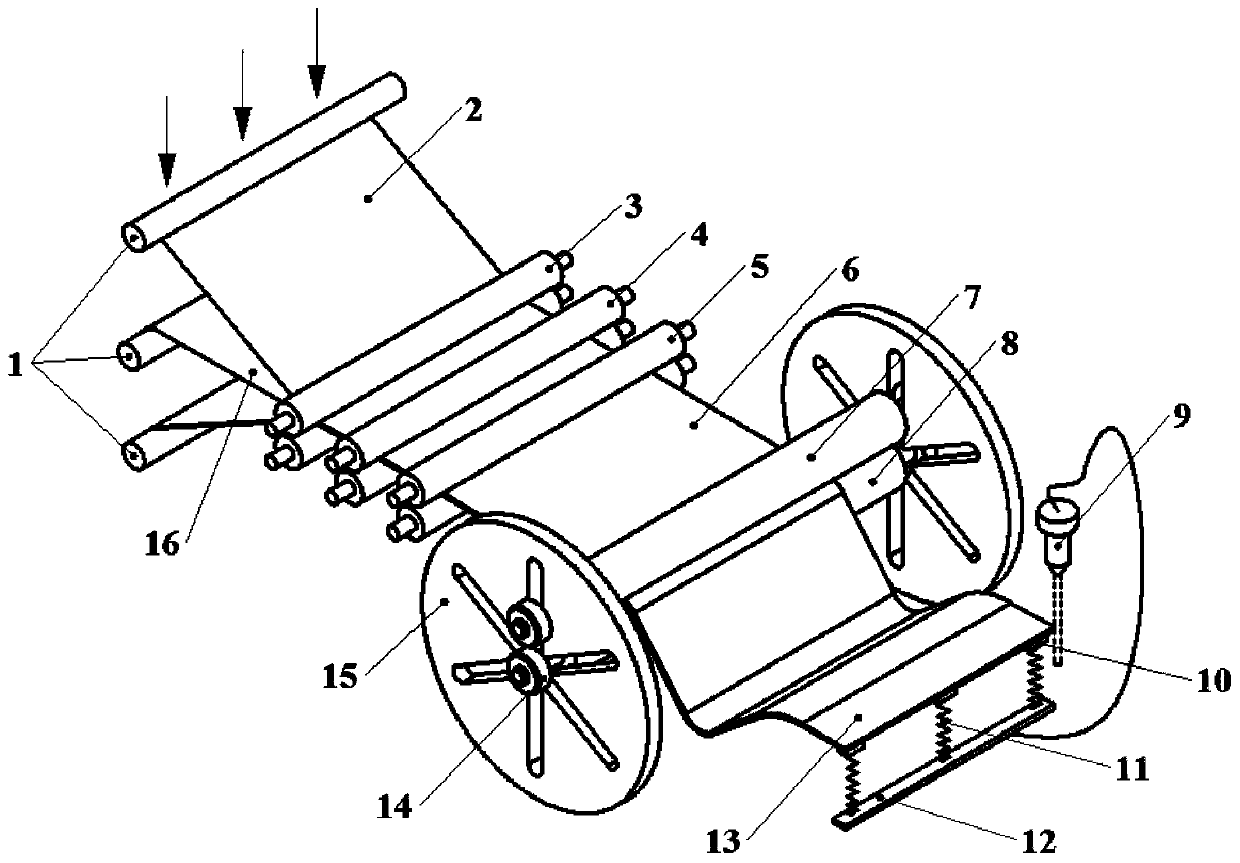

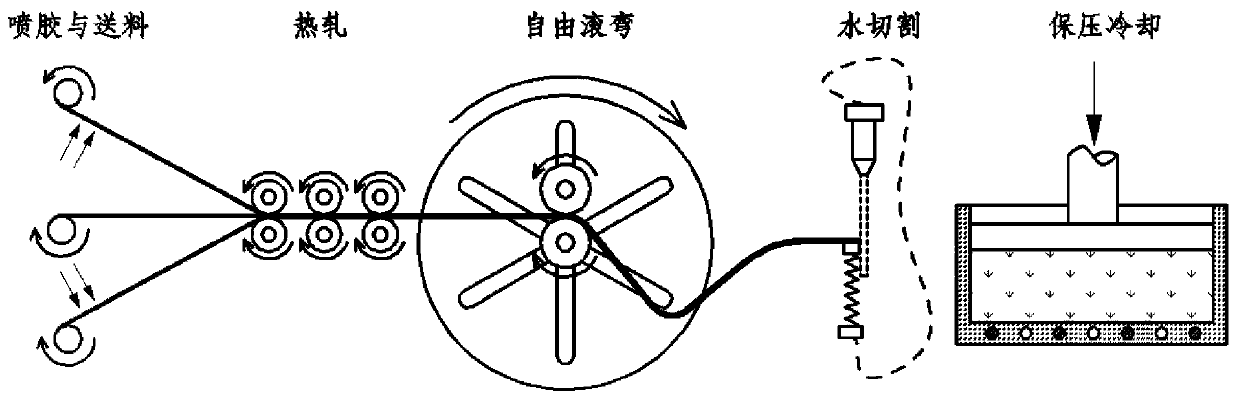

[0049] In the second step, three rolls of surface-treated aluminum alloy coils and two rolls of double-layer glass fiber reinforced epoxy resin prepreg coils (single-layer thickness 0.15mm) are placed on the corresponding feeding rollers according to the interval order ;

[0050] In the third step, the feed roller rotates at a specific linear speed while the spray gun evenly sprays the epoxy resin dispersed in chloroform on the surface of the aluminum alloy coil that needs to be bonded with the glass fiber reinforced epoxy resin composite material. The amount of spray glue is 40g / m on one side 2 ;

[0051] In the fourth step, after the multi-layer coils are stacked, they are drawn into the continuous three-pass high-temperature rolling station, and the excess glue and air are discharged under high t...

Embodiment 2

[0057] In the first step, the TA2 titanium alloy coil with a thickness of 0.3mm is degreased, pickled and anodized with sodium hydroxide;

[0058] In the second step, three rolls of surface-treated titanium alloy coils, two rolls of double-layer carbon fiber reinforced polyether ether copper prepreg coils (single-layer thickness 0.125mm), four rolls of polyether with a thickness of 0.1mm The ether copper film is set on the corresponding feeding roller shaft according to the interval order;

[0059] In the third step, after the multi-layer coils are stacked, they are drawn into the continuous three-pass high-temperature rolling station, and the excess glue and air are discharged under high temperature and high pressure, so that the layers are completely bonded, and the temperature of the rolls is set at 390 ℃, the rolling pressure is set to 0.6MPa;

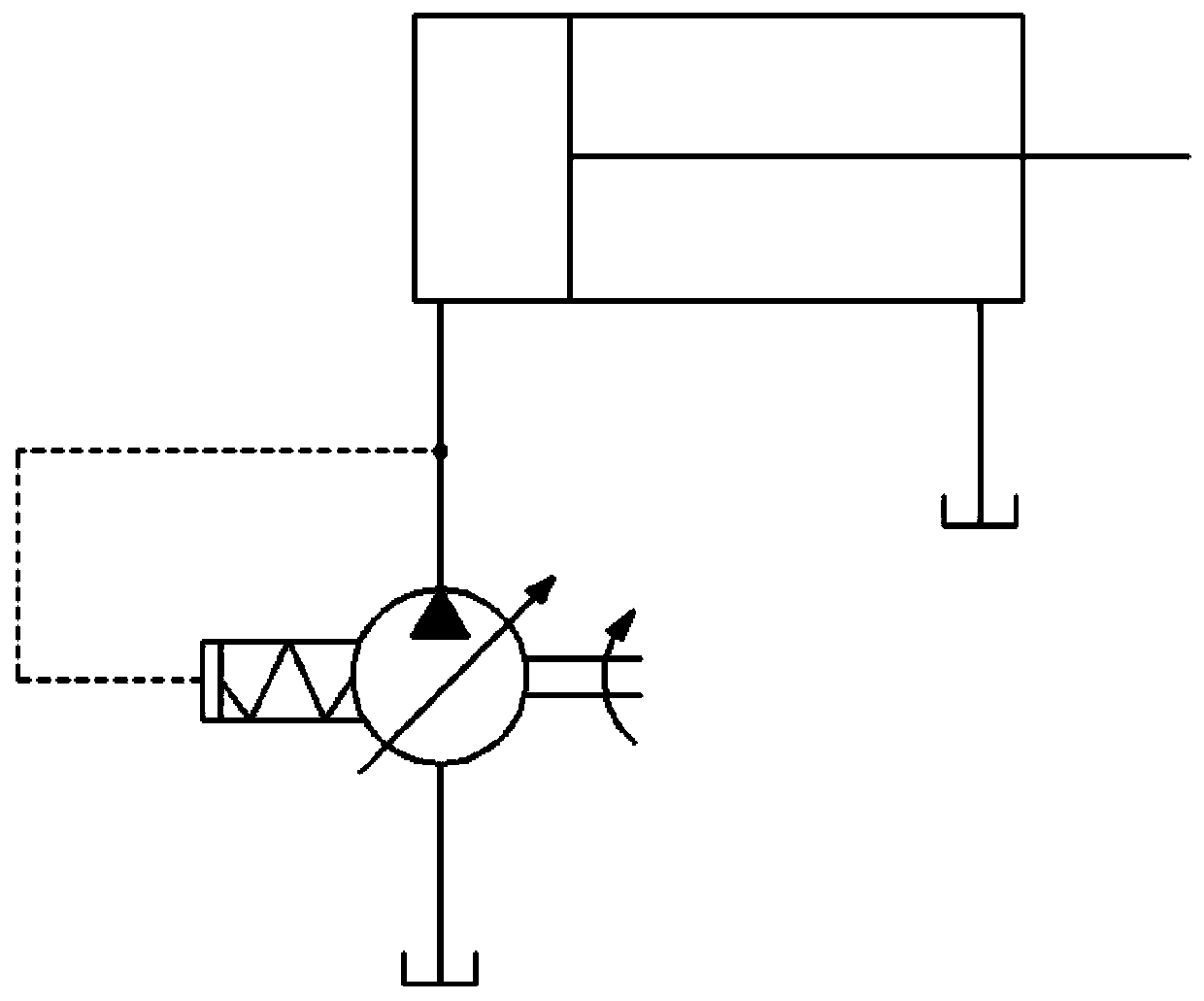

[0060] In the fourth step, the composite sheet after the interlayer airtight lamination enters the free bending station, the fix...

Embodiment 3

[0065] In the first step, the 2024 aluminum alloy coil with a thickness of 0.3mm is degreased, alkaline cleaned, pickled and sandblasted;

[0066] In the second step, two rolls of surface-treated aluminum alloy coils and one roll of double-layer glass fiber reinforced epoxy resin prepreg coils (single-layer thickness 0.15mm) are placed on the corresponding feeding rollers in the order of intervals ;

[0067] In the third step, the feed roller rotates at a specific linear speed while the spray gun evenly sprays the epoxy resin dispersed in chloroform on the surface of the aluminum alloy coil that needs to be bonded with the glass fiber reinforced epoxy resin composite material. The amount of spray glue is 40g / m on one side 2 ;

[0068] In the fourth step, after the multi-layer coils are stacked, they are drawn into the continuous three-pass high-temperature rolling station, and the excess glue and air are discharged under high temperature and high pressure, so that the layers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com