Stripping type water-based optical glass cleaner

An optical glass and peel-off technology, which is applied in the field of cleaning agents, can solve the problems of high content of organic matter in cleaning sewage, increased sewage treatment costs, secondary cleaning pollution, etc., achieves environmentally friendly and easy-to-degrade components, reduces sewage treatment costs, and is convenient The effect of unified collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

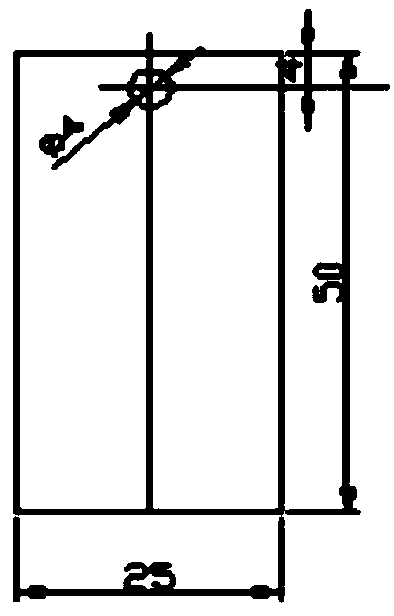

Image

Examples

Embodiment 1

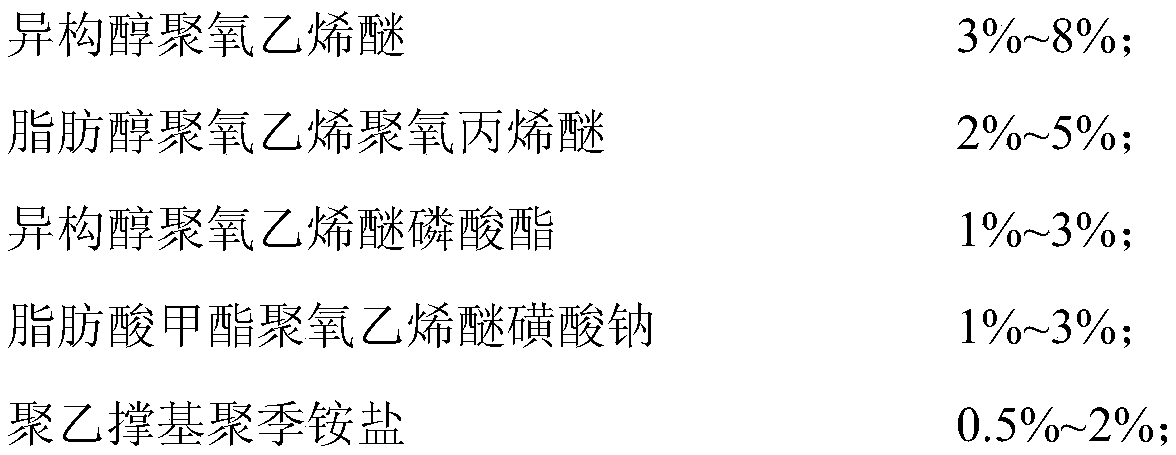

[0047] 1) Add 5kg of sodium citrate and 2kg of EDTA-2Na into 82.3kg of water and stir to dissolve to form a uniform solution.

[0048] 2) Polymerize 1kg of isooctanol polyoxyethylene ether phosphate, 3kg of isooctanol polyoxyethylene ether-7, 5kg of octanol polyoxyethylene polyoxypropylene ether (EO:PO=6:4), and 1kg of fatty acid methyl ester. Sodium oxyethylene ether sulfonate, 0.5 kg polyethoxy dodecyl dimethyl ammonium chloride polyquaternary ammonium salt, 0.2 kg perfluoroalkyl betaine are sequentially added to the solution obtained in step 1), when the first After the ingredients are completely dissolved by stirring, add the next ingredient until all the ingredients are stirred and dissolved to obtain a uniform solution; the dissolution temperature is 30°C, and the stirring speed is 50r / min.

[0049] 3) The solution obtained in step 2) was aged at 30° C. for 2 hours, and then filtered with a 300-mesh sieve to obtain the peeling water-based optical glass cleaning agent of this ...

Embodiment 2

[0051] 1) Add 4kg of sodium citrate, 4kg of sodium metasilicate and 3kg of EDTA-3Na to 77.5kg of water and stir to dissolve to form a uniform solution.

[0052] 2) Combine 2kg isooctanol polyoxyethylene ether phosphate, 5kg isodeca alcohol polyoxyethylene ether-7, 2kg nonyl alcohol polyoxyethylene polyoxypropylene ether (EO:PO=7:3), 1kg fatty acid methyl ester Sodium polyoxyethylene ether sulfonate, 1kg polyethoxy didecyl methyl ammonium chloride polyquaternary ammonium salt, 0.5 kg perfluoroalkyl polyoxyethylene ether were added to the solution obtained in step 1) in sequence, when the first After one component is completely dissolved by stirring, add the next component until all the components are stirred and dissolved to obtain a uniform solution; the dissolution temperature is 40°C, and the stirring speed is 50r / min.

[0053] 3) The solution obtained in step 2) was aged at 40° C. for 2.5 hours, and then filtered with a 300-mesh sieve to obtain the peeling water-based optical gl...

Embodiment 3

[0055] 1) Add 3kg of sodium citrate, 5kg of triethanolamine and 2kg of sodium gluconate to 73.8kg of water and stir to dissolve to form a uniform solution.

[0056] 2) Combine 2kg of isodecyl alcohol polyoxyethylene ether phosphate, 7kg of isooctanol polyoxyethylene ether-8, 3kg of undecyl alcohol polyoxyethylene polyoxypropylene ether (EO:PO=6.5:3.5), 2kg of fatty acid methyl ester Sodium polyoxyethylene ether sulfonate, 1.5kg polypentanol propionate didodecyl dimethyl ammonium chloride polyquaternary ammonium salt, 0.7kg sodium perfluoroalkyl ethoxy sulfate are sequentially added to step 1) to obtain In the solution, when the first ingredient is completely dissolved by stirring, add the next ingredient until all the ingredients are stirred and dissolved to obtain a uniform solution; the dissolution temperature is 40°C, and the stirring speed is 50r / min.

[0057] 3) The solution of step 2) was aged at 40°C for 2.5 hours, and then filtered with a 300-mesh sieve to obtain the peelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com