Selenium-enriched rice plant selenoprotein capsule material and preparation method thereof

A technology of plant selenoprotein and selenium-enriched rice, which is applied in the field of selenium-enriched rice plant selenoprotein capsule materials and its preparation, can solve the problems of delayed dissolution of capsule contents in capsule shells, poor water solubility of gelatin shells, and broken capsules. Avoid viscosity and strength decrease, improve elasticity, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

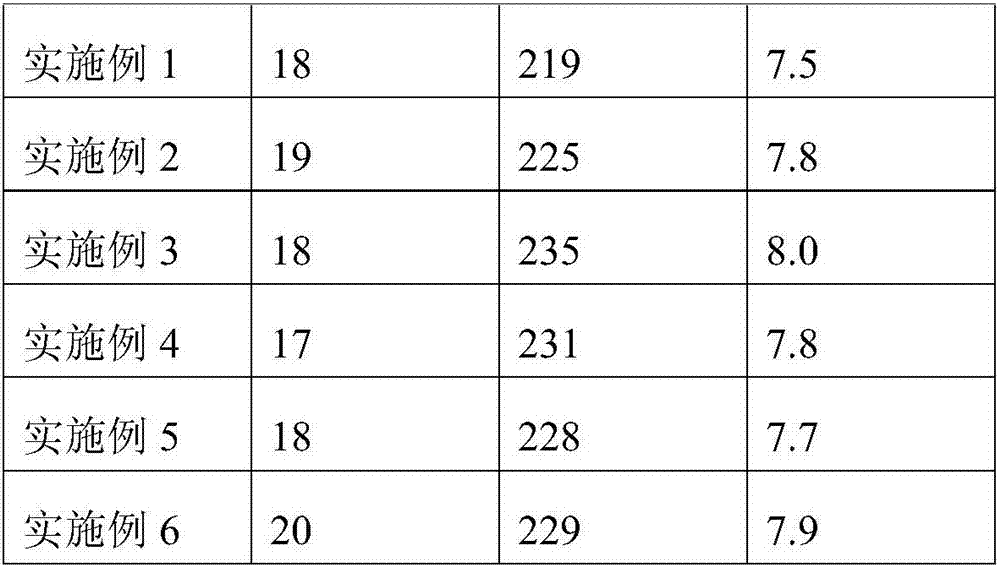

Examples

Embodiment 1

[0030] 1. Preliminary preparation:

[0031] Preparation of selenium-enriched rice plant selenoprotein: in parts by weight, put 200 parts of selenium-rich rice into 5000 parts of acidic solution and soak for 4 hours, grind into a slurry and filter, add 1000 parts of extract and 3 parts of Surfactant, extract at 25°C for 150min, filter with an ultrafiltration membrane, add 4 times the volume of acetone solution to the resulting liquid for precipitation, take the precipitate at a temperature of 55°C, and dry it with a moisture content of 1 %, under the condition that the color difference value is 12, the vacuum drying treatment is carried out to obtain the selenium-enriched rice plant selenoprotein.

[0032] Preparation of the extract solution: in parts by weight, mix 1000 parts of pure water, 10 parts of sodium chloride and 12 parts of 8% sodium hydroxide solution, and stir evenly to obtain the extract solution.

[0033] The substance prepared above is used in the preparation m...

Embodiment 2

[0037] 1. Preliminary preparation:

[0038] Preparation of selenium-enriched rice plant selenoprotein: by weight parts, put 200 parts of selenium-rich rice into 5000 parts of acidic solution and soak for 4.5 hours, grind into a slurry and filter, add 1000 parts of extract and 4 parts to the filtrate Parts of surfactant, extract at 33°C for 170min, filter with ultrafiltration membrane, add 4 times the volume of acetone solution to the resulting liquid for precipitation, take the precipitate at a temperature of 58°C, and the moisture content after drying 1.3% and a color difference of 13 to carry out vacuum drying treatment to obtain selenium-enriched rice plant selenoprotein.

[0039] Preparation of the extract solution: in parts by weight, 1000 parts of pure water, 13 parts of sodium chloride and 25 parts of 8.5% sodium hydroxide solution were mixed, and the extract was obtained after uniform stirring.

[0040] The substance prepared above is used in the preparation method of...

Embodiment 3

[0044] 1. Preliminary preparation:

[0045] Preparation of selenium-enriched rice plant selenoprotein: in parts by weight, put 200 parts of selenium-rich rice into 5000 parts of acidic solution and soak for 5 hours, grind into slurry and filter, add 1000 parts of extract and 5 parts of Surfactant, extract at 35°C for 190min, filter with an ultrafiltration membrane, add 4 times the volume of acetone solution to the resulting liquid for precipitation, take the precipitate at a temperature of 61°C, and dry it with a moisture content of 1.4 %, under the condition that the color difference value is 13, vacuum drying is carried out to obtain selenium-enriched rice plant selenoprotein.

[0046] Preparation of the extract solution: in parts by weight, 1000 parts of pure water, 18 parts of sodium chloride and 19 parts of 9% sodium hydroxide solution were mixed, and the extract was obtained after uniform stirring.

[0047] The substance prepared above is used in the preparation method ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com