Preparation method for composite material of transitional metal sulfide loaded by hollow carbon nano tube

A carbon nanotube and transition metal technology, applied in carbon nanotubes, chemical instruments and methods, nickel sulfide, etc., can solve the problems of poor electrical conductivity, limited electrochemical performance, cumbersome and other problems, achieve easy volatilization removal, avoid template Remove the effect of the step

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

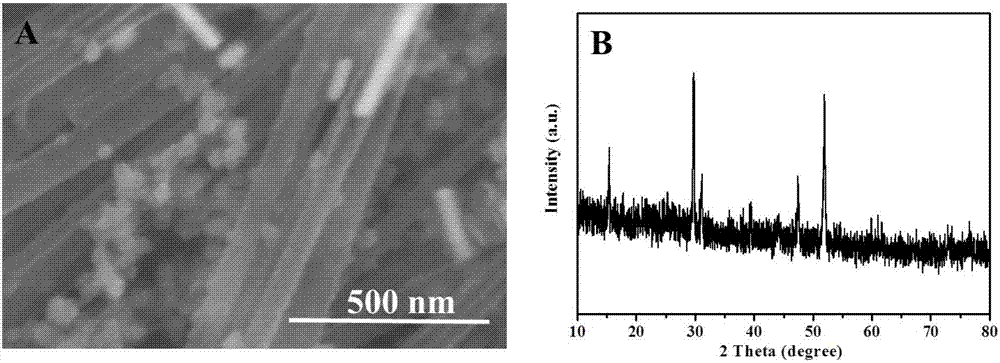

Embodiment 1

[0018] (1) Polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (P123) is a surfactant, trimethylolmethane (Tris) is a pH buffer, dissolved in deionized water . P123:Tris:water mass ratio 1:1:1000, stir evenly, obtain transparent solution A;

[0019] (2) Using cobalt chloride as a metal source and dopamine hydrochloride as a carbon source and a nitrogen source, dissolving the metal salt and dopamine hydrochloride in deionized water. The molar ratio of the three is 1:(0.5~2):4000 to obtain a transparent solution B;

[0020] (3) Mix solution B and solution A according to the volume ratio of 2:1, and react at room temperature for 24 hours to obtain a dark green dispersion;

[0021] (4) The above product was centrifuged, washed, dried, and then calcined at 900° C. for 3 h under Ar atmosphere.

[0022] After testing, the resulting product is Co 9 S 8 Composites of particles and hollow carbon nanotubes.

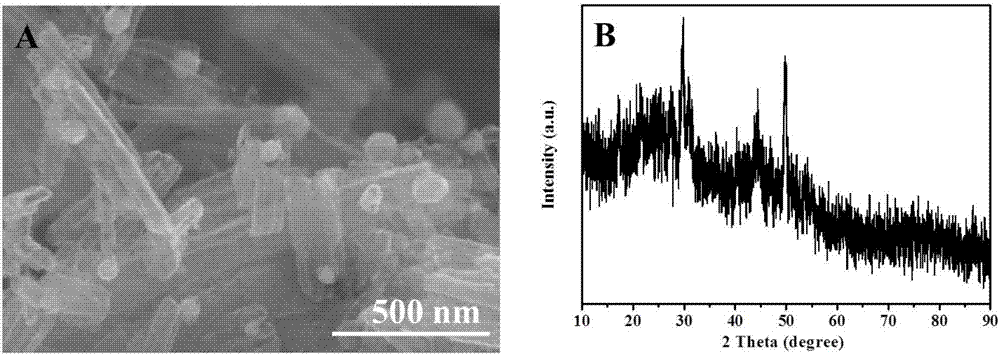

Embodiment 2

[0024] (1) Polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (P123) is a surfactant, trimethylolmethane (Tris) is a pH buffer, dissolved in deionized water . P123:Tris:water mass ratio 1:1:1000, stir evenly, obtain transparent solution A;

[0025] (2) Using nickel chloride as the metal source and dopamine hydrochloride as the carbon source and nitrogen source, dissolving the metal salt and dopamine hydrochloride in deionized water. The molar ratio of the three is 1:(0.5~2):4000 to obtain a transparent solution B;

[0026] (3) Mix solution B and solution A according to the volume ratio of 2:1, and react at room temperature for 24 hours to obtain a dark green dispersion;

[0027] (4) The above product was centrifuged, washed, dried, and then calcined at 900° C. for 3 h under Ar atmosphere.

[0028] After testing, the resulting product is Ni 3 S 2 Composites of particles and hollow carbon nanotubes.

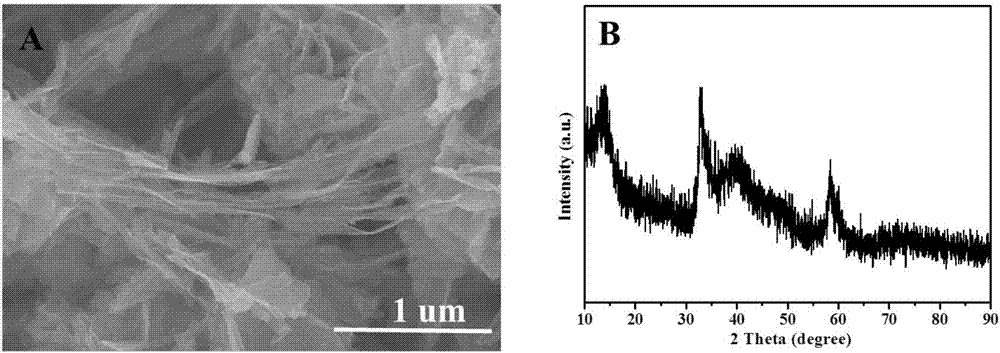

Embodiment 3

[0030] (1) Polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (P123) is a surfactant, trimethylolmethane (Tris) is a pH buffer, dissolved in deionized water . P123:Tris:water mass ratio 1:1:1000, stir evenly, obtain transparent solution A;

[0031] (2) Using ammonium molybdate as the metal source, dopamine hydrochloride as the carbon source and nitrogen source, and dissolving the metal salt and dopamine hydrochloride in deionized water. The molar ratio of the three is 1:(0.5~2):4000 to obtain a transparent solution B;

[0032] (3) Mix solution B and solution A according to the volume ratio of 2:1, and react at room temperature for 24 hours to obtain a dark green dispersion;

[0033] (4) The above product was centrifuged, washed, dried, and then calcined at 900° C. for 3 h under Ar atmosphere.

[0034] After testing, the resulting product is MoS 2 Composites with hollow carbon nanotubes.

[0035] What is not mentioned in the present invention is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com