Graphene/polymer three-dimensional foam substrate, and preparation method and application thereof

A graphene and polymer technology, applied in the field of graphene foam composite materials, can solve the problems of graphene interlayer stacking, poor mechanical properties, volume shrinkage, etc., and achieve the effects of simple preparation process, excellent electrical conductivity, and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

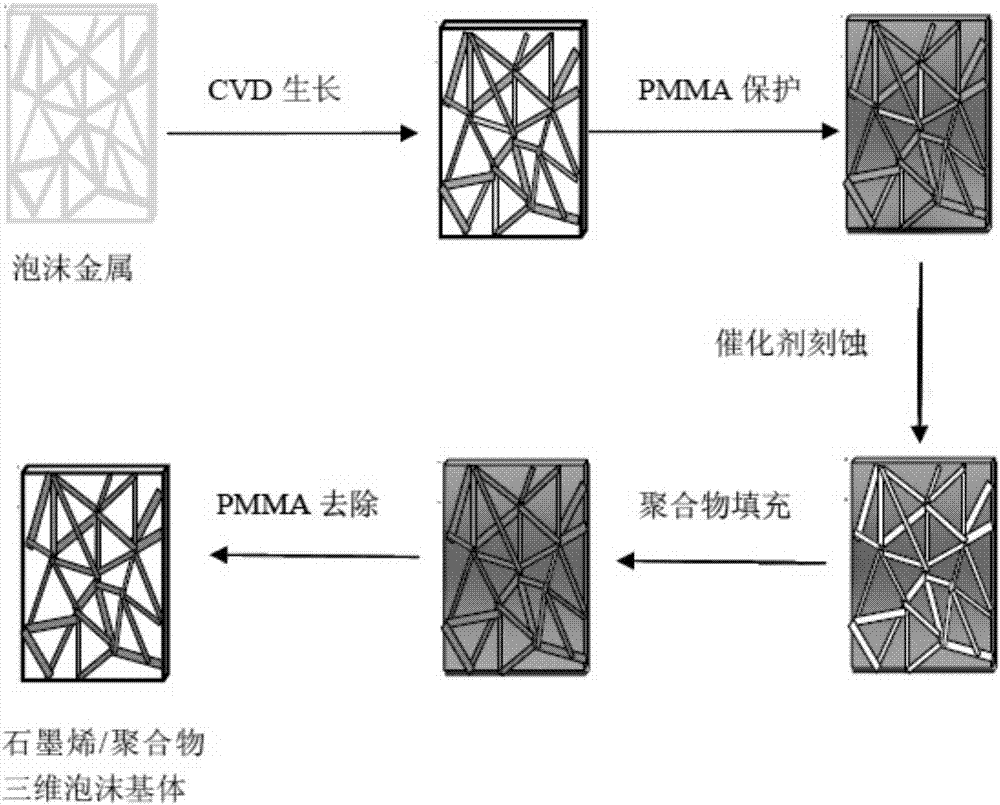

[0024] A method for preparing a graphene / polymer three-dimensional foam matrix provided by an aspect of the embodiments of the present invention includes:

[0025] A carbon source is introduced by chemical vapor deposition (CVD), and graphene is grown on the metal foam catalyst to form a three-dimensional graphene / metal foam catalyst composite;

[0026] The metal foam catalyst skeleton in the three-dimensional graphene / foam metal catalyst composite is replaced by a polymer by a template replacement method to obtain a flexible graphene / polymer three-dimensional foam matrix.

[0027] As one of the preferred schemes, the preparation method specifically includes:

[0028] Forming polymethyl methacrylate (PMMA) protective layer and filling layer respectively in the surface and pore structure of described three-dimensional graphene / foam metal catalyst composite;

[0029] removing the metal foam catalyst framework in the composite with an etchant to form a three-dimensional framewor...

Embodiment 1

[0058] Embodiment 1: refer to figure 1 As shown, put nickel foam in a quartz tube, then put it into a tube furnace, raise the temperature in the tube furnace to 1000°C, and keep it for 10 minutes. At this time, the atmosphere environment is: methane is 30 sccm, hydrogen is 200 sccm, The argon gas is 200 sccm, and the gas pressure is normal pressure. After the growth is completed, the quartz tube is taken out and cooled to room temperature, and then the anisole solution with a concentration of about 4wt% PMMA is coated on the surface of the nickel foam for growing graphene, dried, and put into 1M FeCl 3 / 0.1M HCl solution for etching, washed with water and dried, and finally soaked in polydimethylsiloxane (PDMS), vacuumized, kept for 2 hours, cured at 80 ° C, and then in acetone solution at about 50 ° C Soak in medium for about 24 hours, remove the PMMA protective layer, and dry to form a graphene / PDMS three-dimensional foam matrix. The electrical conductivity of the foam mat...

Embodiment 2

[0059] Embodiment 2: refer to figure 1 As shown, put copper foam in a quartz tube, then put it into a tube furnace, raise the temperature in the tube furnace to 1000°C, and keep it for 10 minutes. At this time, the atmosphere environment is: methane is 30 sccm, hydrogen is 200 sccm, The argon gas is 200 sccm, and the gas pressure is maintained at 10 torr. After the growth is completed, the quartz tube is taken out and cooled to room temperature, and then the anisole solution of PMMA is coated on the copper foam surface of the graphene growth, dried, and put into 1M FeCl 3 / 0.1M HCl solution for etching, and washing and drying, and finally soaked in styrene-butadiene rubber, vacuumized, kept for 2 hours, cured at 80°C, and then soaked in acetone solution at about 50°C for 24 hours to remove PMMA The protective layer is dried to form a graphene / styrene-butadiene rubber three-dimensional foam matrix. The conductivity of the foam matrix is about 1-10 S / m, the thermal conductivi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com