Negative electrode material of lithium ion battery and preparation method of negative electrode material, and lithium ion battery

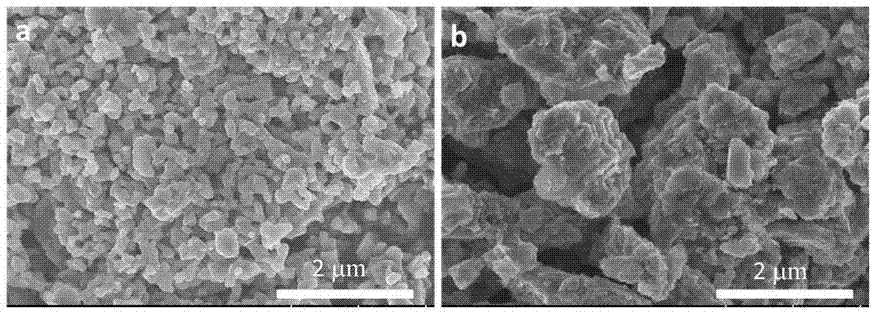

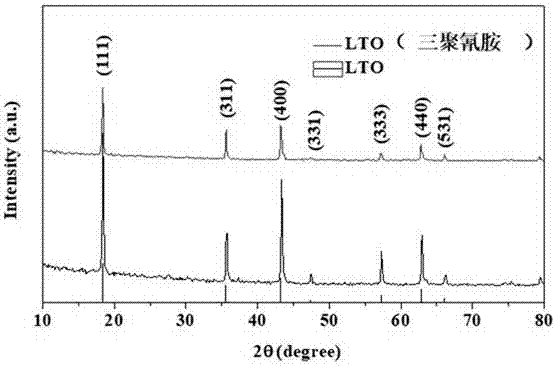

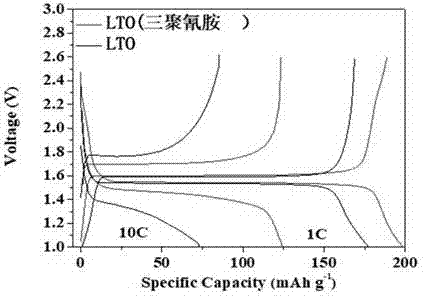

A technology for lithium ion batteries and negative electrode materials, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of reducing the tap density of lithium titanate materials, difficult to ensure the uniformity of carbon-based materials, and complex nanostructure design process. , to achieve the effect of low price, good uniformity and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Get the lithium source as lithium carbonate, the addition ratio of lithium source, melamine and tetrabutyl titanate is:

[0032] Li:melamine=1:62.5, Li:Ti=4.02:5.

[0033] In the reactant addition, since the nitrogen-doped lithium titanate will be prepared, the melamine as the nitrogen source must be excessive, if the addition is too little, it will be difficult to carry out sufficient nitrogen doping, if the addition is too much, the raw materials will be wasted, and the The process leading to subsequent processing is time consuming. According to the molecular formula Li4Ti5O12 of lithium titanate, the addition amount of tetrabutyl titanate needs to be calculated based on the Ti content in the molecule, and the molar ratio of the Li content in the lithium source is 5:4. However, in the actual preparation process , considering that there is a certain burning loss of Li element during the calcination process, when adding raw materials, the lithium source content is slig...

Embodiment 2

[0037] Get the lithium source as lithium carbonate, the addition ratio of lithium source, melamine and tetrabutyl titanate is:

[0038] Li:melamine=1:32.5, Li:Ti=4.01:5.

[0039] The preparation method of negative electrode material is:

[0040] Put melamine and lithium carbonate into a ball mill jar, add a small amount of ethanol, and ball mill at a speed of 10000r / min for 30min. After the ethanol is completely volatilized, add tetrabutyl titanate, stir until the mixture becomes a uniform gel, and then add distilled water dropwise while stirring the above gel mixture, until all the gel forms a powder again. Put the powder obtained above into a rectangular corundum crucible and place it in the center of a programmable tube furnace, raise the temperature to 300°C at 5°C / min, and keep it for 1 hour; then raise the temperature to 500°C at 5°C / min, and keep it for 2 Hours, then heated up to 800°C at 3°C / min, held for 4 hours, and cooled naturally to obtain a yellow or gray nitro...

Embodiment 3

[0042] Get the lithium source as lithium carbonate, the addition ratio of lithium source, melamine and tetrabutyl titanate is:

[0043] Li:melamine=1:62.5, Li:Ti=4.01:5.

[0044] The preparation method of negative electrode material is:

[0045] Put melamine and lithium carbonate into a ball mill jar, add a small amount of ethanol, and ball mill at a speed of 10000r / min for 30min. After the ethanol is completely volatilized, add tetrabutyl titanate, stir until the mixture becomes a uniform gel, and then add distilled water dropwise while stirring the above gel mixture, until all the gel forms a powder again. Put the powder obtained above into a cuboid corundum crucible and place it in the center of a programmable tube furnace, raise the temperature to 300°C at 5°C / min, and keep it for 1 hour; then raise the temperature to 580°C at 5°C / min, and keep it for 2 After 2 hours, the temperature was raised to 800° C. at 2° C. / min, kept for 2 hours, and after natural cooling, a yello...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com