Preparation method of complex-phase translucent fluorescent ceramics and LED module

A fluorescent ceramic, translucent technology, used in lighting and heating equipment, parts of lighting devices, light sources, etc., can solve the problem of poor consistency and batch stability, reduce the transparency and refractive index of the dispensing layer, and require strict preparation processes and other problems, to achieve the effect of raw material purity and low vacuum degree of sintering equipment, reducing thickness and phosphor concentration, and improving lighting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

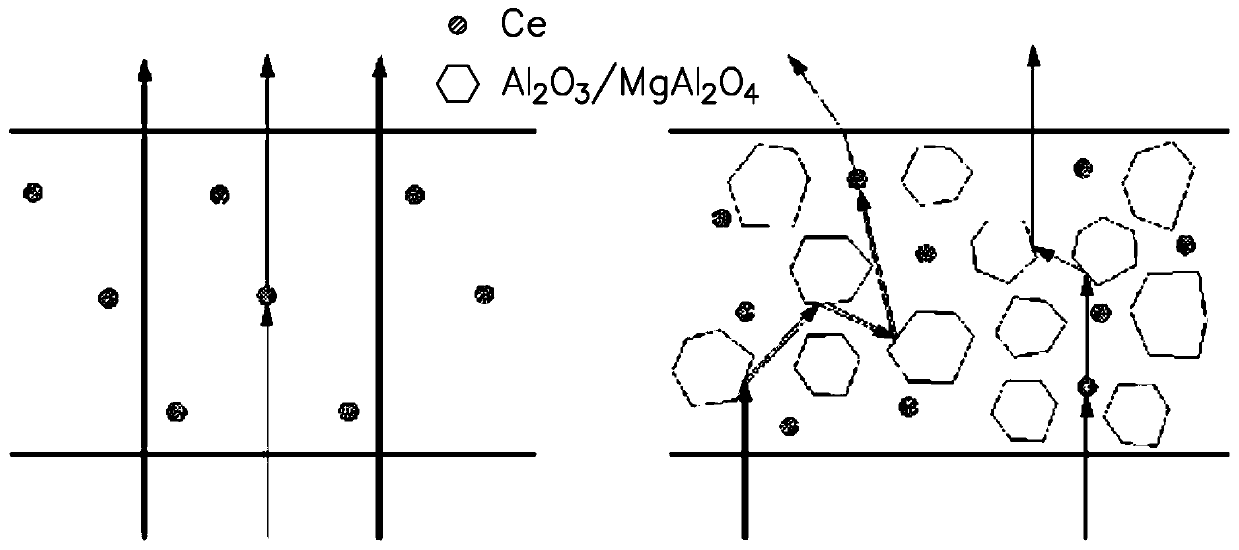

[0030] In an embodiment of the present invention, a method for preparing a complex-phase translucent fluorescent ceramic includes the following steps: providing raw materials, the raw materials include a first-phase phosphor powder and a second-phase ceramic raw material powder, and the first phase fluorescent powder The average grain size of powder grains (D 50 ) is 1 to 10 μm, and the average particle diameter (D 50 ) is 0.5-5 μm, the second-phase ceramic raw material powder and the first-phase phosphor are mixed according to the mass ratio of 0.1-5; Transparent fluorescent ceramic.

[0031] In this embodiment, the composition of the first phase phosphor is Re:YAG (yttrium aluminum garnet, Y 3 al 5 o 12 ), the Re is selected from one of cerium (Ce), lutetium (Lu), europium (Eu), neodymium (Nd), terbium (Tb), ytterbium (Yb) and praseodymium (Pr), and the phosphor The shape of the grains is nearly round. The second phase ceramic raw material powder is selected from alumi...

Embodiment 1

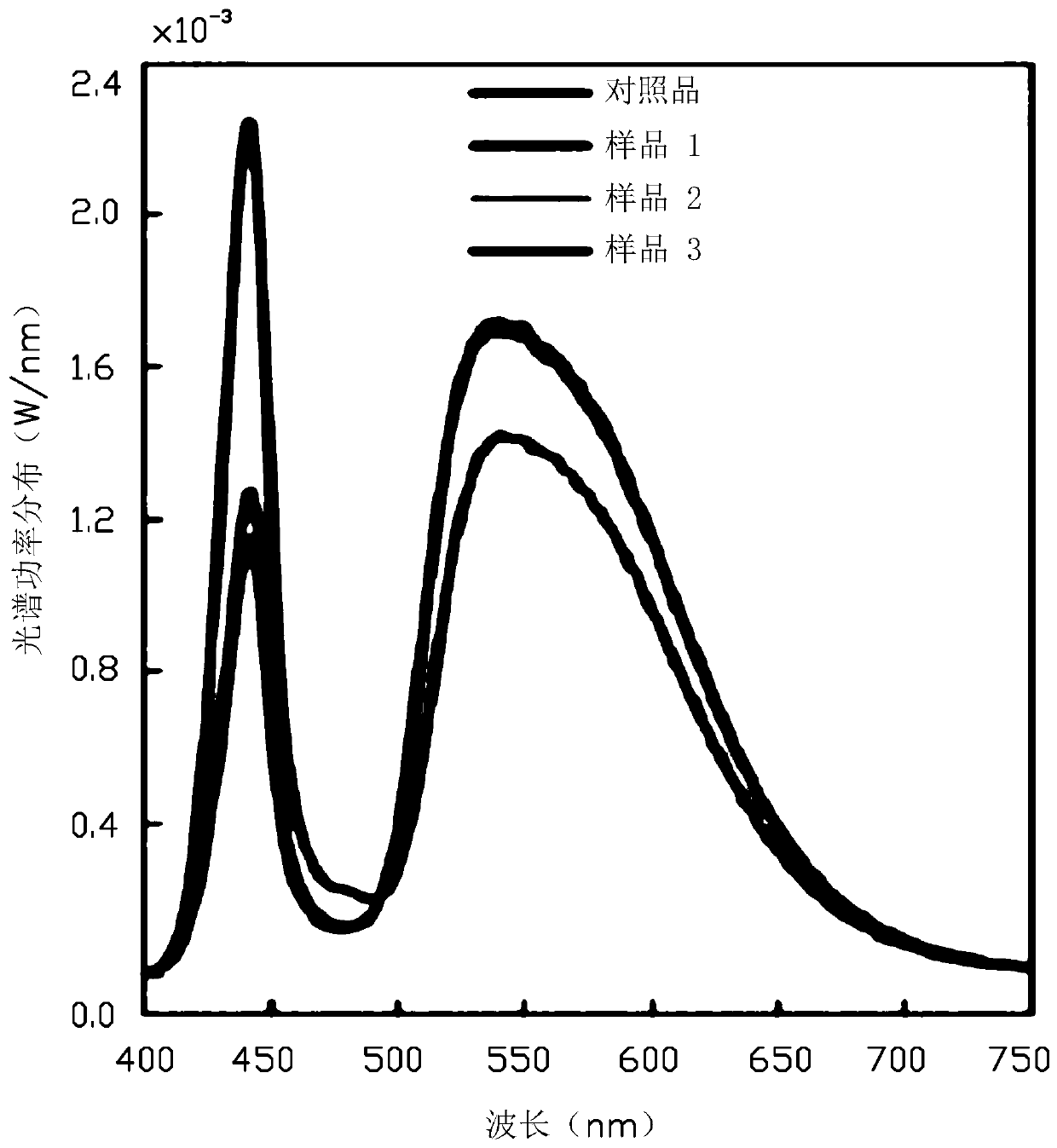

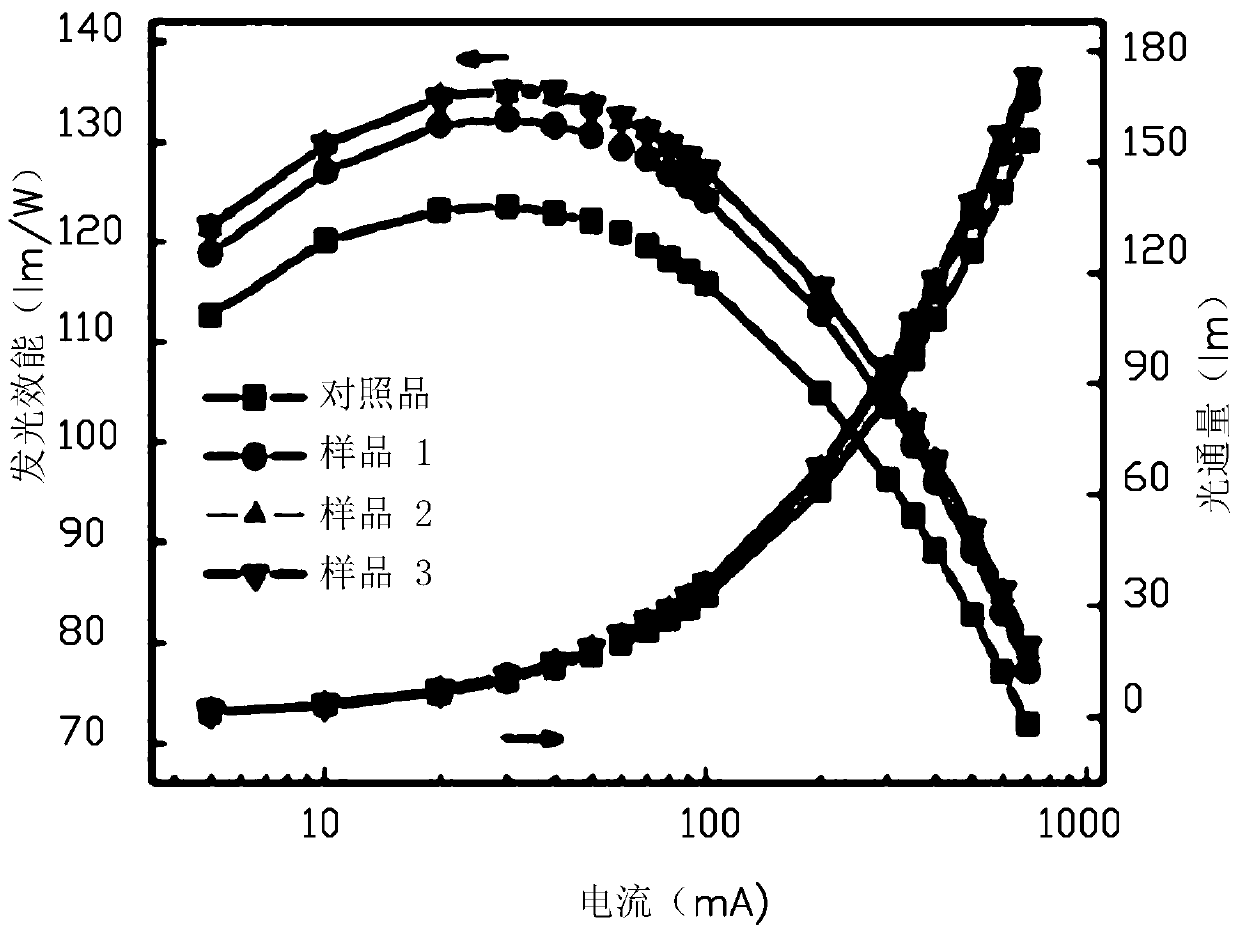

[0048] Weigh D separately 50 =10.5μm commercial YAG (yttrium aluminum garnet) phosphor 12g, D 50 = 1 μm commercial alumina powder 18g, add 0.4wt% tetraethyl orthosilicate (TEOS) and put it into a corundum ball mill jar, use absolute ethanol as a medium on a planetary ball mill, and obtain a mixed suspension after 400r / min ball milling for 10 hours, put Dry in an oven at 80°C for 10 hours to obtain a mixed powder, then pre-press the mixed powder at 10 MPa for 2 minutes, and then cold isostatically press at 200 MPa for 10 minutes to obtain a ceramic green body, and then place the green body in a vacuum sintering furnace for 10 ℃ / min to 1200 ℃, 5 ℃ / min to 1700 ℃, keep warm for 10 hours, cool to room temperature with the furnace, place in a muffle furnace at 5 ℃ / min to 1450 ℃ for annealing treatment for 10 hours, and finally put The ceramic block was cut, ground and polished to obtain a composite translucent ceramic sample 1 with a thickness of 0.4 mm.

Embodiment 2

[0050] Weigh D separately 50 = 5 μm of yttrium oxide (Y 2 o 3 ) powder 4.56g, D 50 = 5μm of cerium oxide (Ce 2 o 3 ) powder 0.04g, D 50 =0.5 μm commercial aluminum oxide powder 25.4g, submicron magnesia (MgO) powder 0.03g are put into the agate ball mill jar, on the planetary ball mill, with dehydrated alcohol as medium, 300r / min ball mill obtains mixed suspension in 8 hours, Dry in an oven at 80°C for 10 hours to obtain a mixed powder, then pre-press the mixed powder at 15 MPa for 1 min, and then press cold isostatically at 250 MPa for 5 min to obtain a ceramic green body, and then place the green body in a vacuum sintering furnace to 10°C / min to 1200°C, 5°C / min to 1650°C, heat preservation for 15 hours, cooling to room temperature with the furnace, annealing in a muffle furnace at 5°C / min to 1450°C for 5 hours, and finally The ceramic block was cut, ground and polished to obtain a composite translucent ceramic sample 2 with a thickness of 0.4 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com