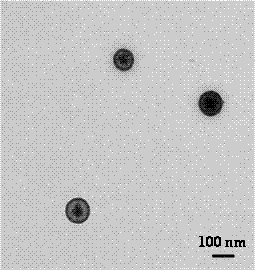

Preparation method of core-shell graphene quantum dot @ mesoporous silica nano-material

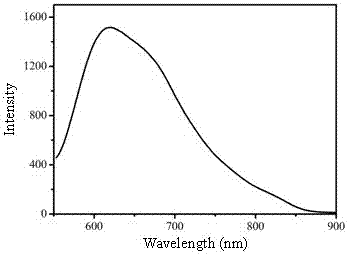

A technology of graphene quantum dots and mesoporous silica, which is applied in the field of nano-fluorescent materials, can solve the problems of small size and unfavorable application of GQDs, and achieve the effects of rich surface groups, excellent fluorescent properties, and efficient drug loading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Preparation method of core-shell GQDs@hMSN:

[0034] (1) Weigh 4-bromobenzyl bromide and N,N-dimethyldodecylamine (molar ratio 1:1.3) and dissolve in dichloromethane-methanol solution (V:V=3:2) , stirred at room temperature for 12 h under a nitrogen atmosphere, the reaction solution was concentrated by distillation under reduced pressure, the concentrated solution was transferred to diethyl ether to disperse, and left to stand until the precipitate was completely separated out. The precipitate was filtered and vacuum-dried to obtain a white crystalline solid, hereinafter referred to as "compound 1".

[0035] (2) Weigh compound 1,3-thiophene boronic acid, sodium carbonate and 4-(triphenylphosphine) palladium (Pd(PPh 3 ) 4 ) (molar ratio 1:4.7:0.17:0.86), dissolved in ethanol-water solution (V:V=2:1), heated to 90°C under nitrogen atmosphere, and refluxed for 6h. The reaction solution was distilled under reduced pressure to remove ethanol, the residue was extracted wit...

Embodiment 1-6

[0041] Examples 1-6 all adopt the above method to prepare GQDs@hMSN nanoparticles, the difference is that the fluorescence performance of GQDs is controlled by adjusting the temperature and reaction time of the high-pressure reactor in step (4); Add different amounts of TEOS to control the particle size of hMSN; adjust the different etching temperature and time used in step (6) to control the shell thickness of hMSN. The relevant experimental results are as follows:

[0042] The synthesis conditions of GQD quantum dots in each embodiment of table 1

[0043]

[0044]

[0045] GQDs products are generated from GQDs precursors in a high-pressure reactor. The higher the reaction temperature, the shorter the reaction time; the amount of TEOS added determines the diameter of the formed shell silica, and the greater the amount added, the final GQDs@hMSN particles will be generated The larger the diameter; the temperature and time for etching silicon dioxide with sodium carbonat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com