Recycled three-in-one cleaning agent for ferrous sulfide passivation, sulfur-ammonia-amine deodorization and stress corrosion resistance of austenitic stainless steel polythionic acid

A technology of austenitic stainless steel and ferrous sulfide, applied in the direction of metal material coating process, etc., can solve the problems of inability to reach the cleaning end point, increase the corrosion rate of carbon steel, and exceed the standard of ammonia nitrogen in sewage, so as to overcome the risk of cleaning quality and save construction. The effect of less time and dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Add 910kg of water to the recycling device; add 5kg of polydimethylsiloxane to the water, stir to dissolve, and let stand; then add surfactant 10kg OP-10 and 5kg of LAS, stir to dissolve, let stand; then slowly add 5kg hydrogen peroxide, 20kg ferric sulfate, 10kg sodium bicarbonate, 10kg disodium EDTA, 5kg ethylenediaminetetramethylene phosphoric acid, 5kg sodium polyphosphate, 10kg polyacrylate sodium, 5kg ferric ammonium citrate, stir to dissolve, then adjust the obtained The pH of the solution was obtained to obtain 1 ton of three-in-one cleaning agent with a pH value of 8.2.

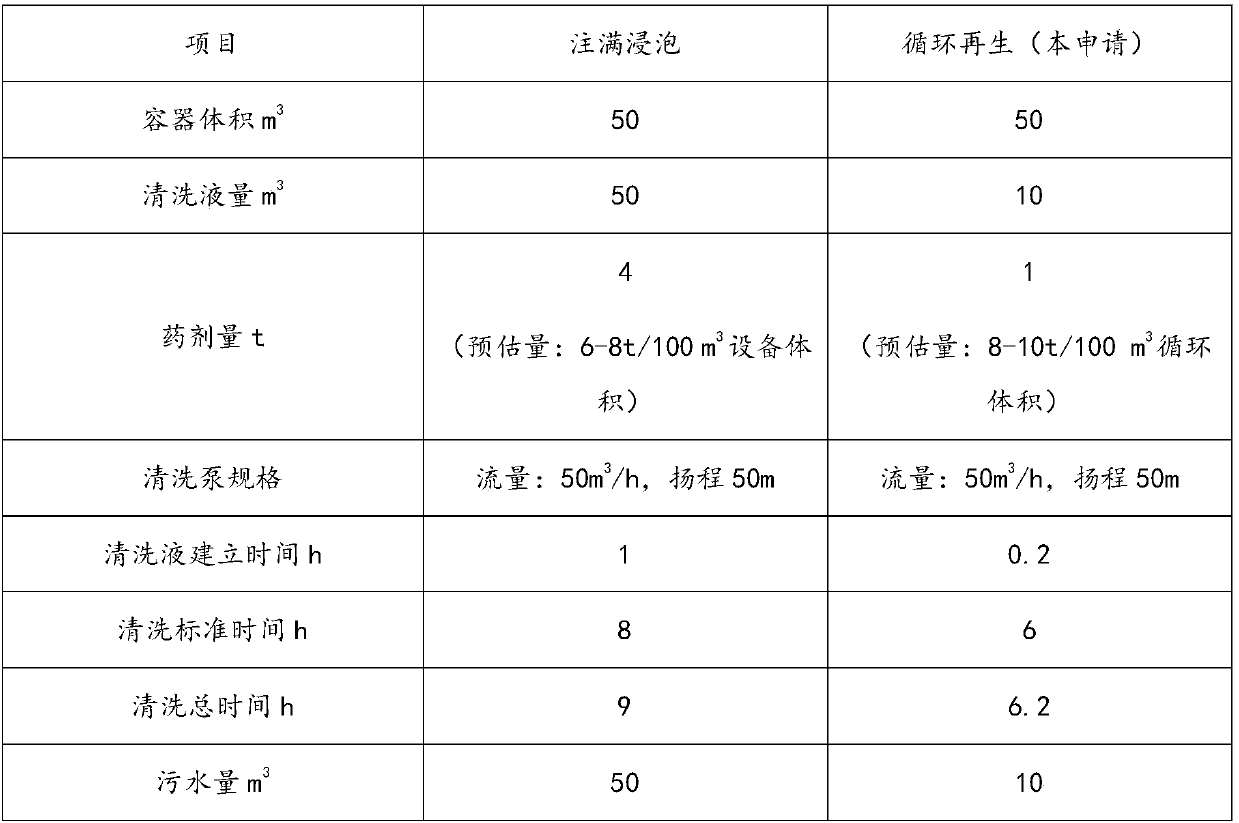

[0040] 1 ton of three-in-one cleaning agent prepared in Example 1 is diluted 10 times with water, and added to a volume of 50m 3 In the disulfide separation tank of the sweetening system, it has been detected that the disulfide separation tank contains ferrous sulfide and sulfide, which has a pungent smell. Start the cycle regeneration device to implement cycle cleaning, the cleaning time is ...

Embodiment 2

[0046] Add 1770kg of water to the recycling device; add 10kg of polydimethylsiloxane to the water, stir to dissolve, and let stand; then add surfactants 25kg OP-10 and 10kg of LAS, stir to dissolve, let stand; then slowly add 25kg hydrogen peroxide, 50kg iron sulfate, 20kg sodium bicarbonate, 20kg disodium EDTA, 15kg ethylenediaminetetramethylene phosphoric acid, 10kg sodium polyphosphate, 20kg polyacrylate sodium, 25kg ferric ammonium citrate, stirring and dissolving, and then The pH of the obtained solution was adjusted to obtain 2 tons of three-in-one cleaning agent with a pH value of 6.1.

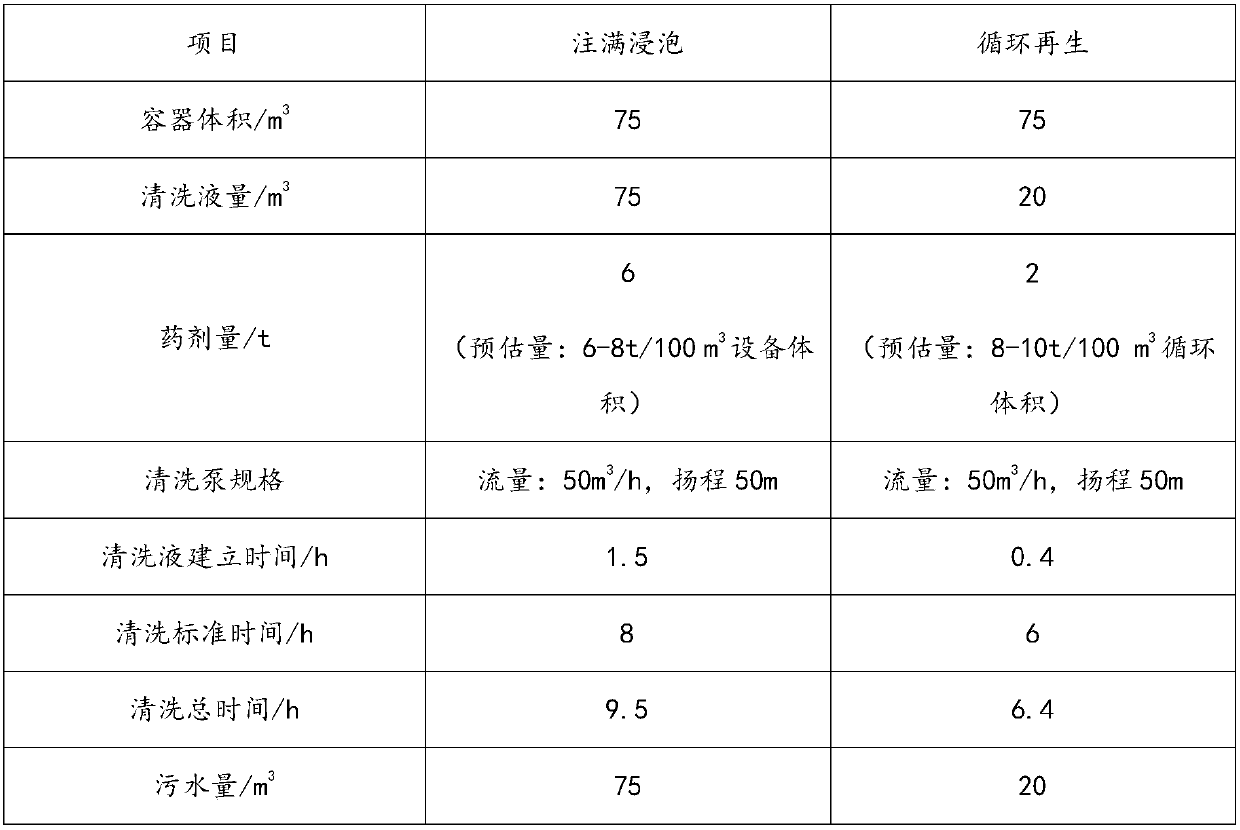

[0047] The 2 tons of three-in-one cleaning agent that embodiment 2 is made dilutes 10 times with water, joins volume and is 75m 3 In the rich liquid flash tank of the desulfurization system, it has been detected that the rich liquid flash tank contains ferrous sulfide and ammonia liquid, and has an ammonia odor. Start the cycle regeneration device to implement cycle cleaning, the clean...

Embodiment 3

[0053] Add 1770kg of water to the recycling device; add 20kg of polydimethylsiloxane to the water, stir to dissolve, and let stand; then add surfactant 40kg OP-10 and 15kg of LAS, stir to dissolve, let stand; then slowly add 20kg hydrogen peroxide, 60kg ferric sulfate, 60kg sodium bicarbonate, 30kg disodium EDTA, 20kg ethylenediaminetetramethylene phosphoric acid, 20kg sodium polyphosphate, 30kg polyacrylate sodium, 30kg ferric ammonium citrate, stirring and dissolving, and then The pH of the obtained solution was adjusted to obtain 3 tons of three-in-one cleaning agent with a pH value of 9.4.

[0054] 3 tons of three-in-one cleaning agent that embodiment 3 is made dilutes 10 times with water, joins volume and is 150m 3 In the hot high-separation tank of the hydrogenation reaction system, it has been detected that the hot high-separation tank contains ferrous sulfide and polythionic acid. Start the cycle regeneration device to implement cycle cleaning, the cleaning time is 6h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com