Method for achieving growth of monocrystalline silicon through Czochralski method

A technology for growing single crystal silicon and single crystal silicon ingots, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve problems such as hindering use and uncontrollable growth of silicon dioxide, so as to reduce the amount of use and reduce leakage. Current, the effect of reducing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

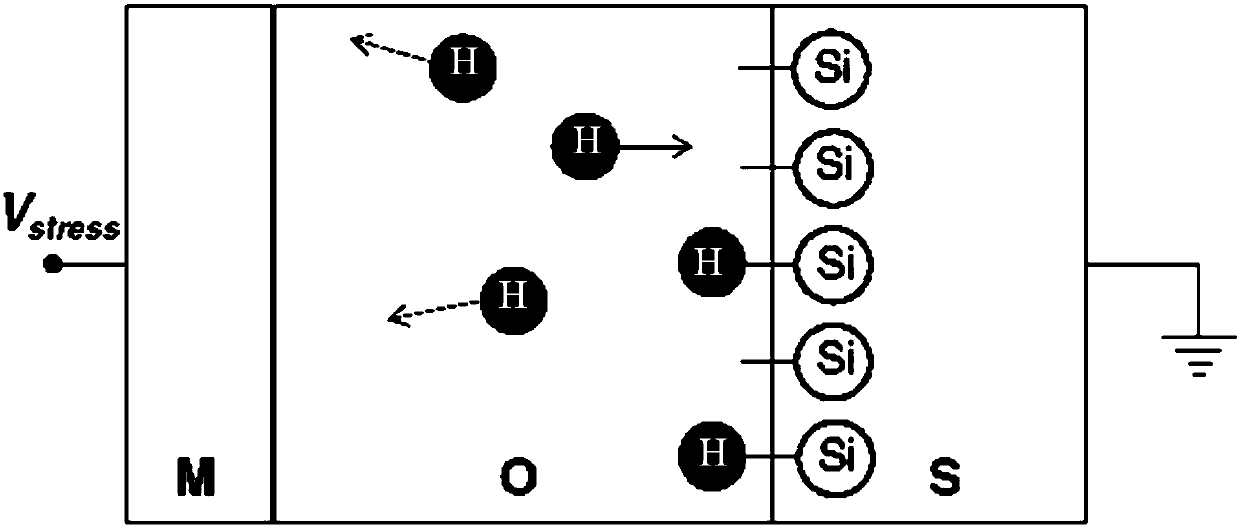

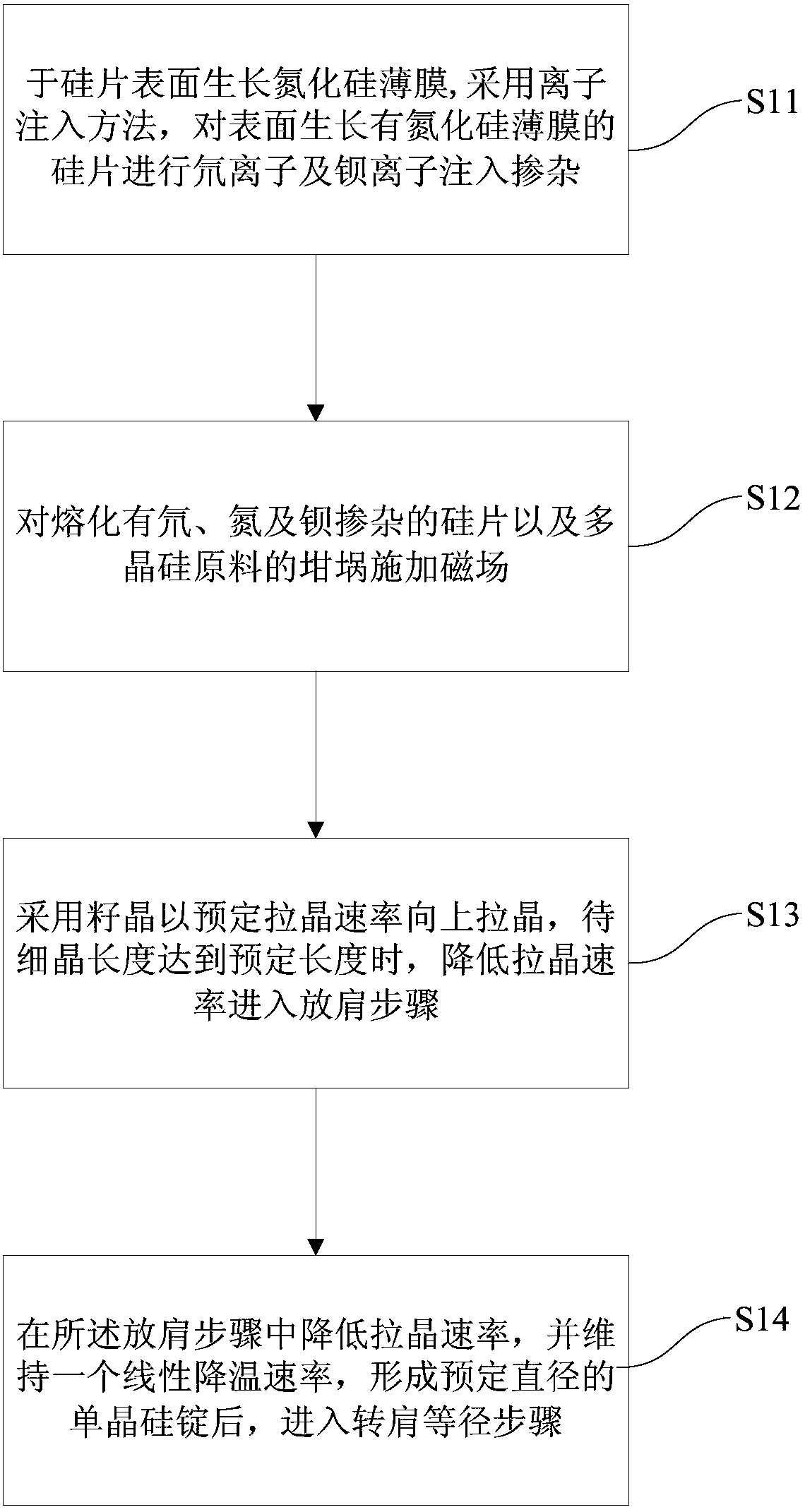

[0036] Such as Figure 2 ~ Figure 3 As shown, the present embodiment provides a method for Czochralski growth of single crystal silicon, the method comprising the following steps:

[0037] Such as image 3 As shown, first perform step 1) S11, provide deuterium, nitrogen and barium-doped silicon wafers and polysilicon raw materials, put the silicon wafers and polysilicon raw materials into a crucible for fusion, and put the silicon wafers and polysilicon raw materials into Gas is introduced into the crucible while the gas includes argon.

[0038] In this embodiment, the preparation of the silicon wafer doped with deuterium, nitrogen, and barium includes the steps of: growing a silicon nitride film on the surface of the silicon wafer; Deuterium ion and barium ion implantation doping.

[0039] Wherein, the deuterium ions and barium ions may be implanted into the silicon wafer sequentially, or may be implanted into the silicon wafer at one time at the same time. In this embodi...

Embodiment 2

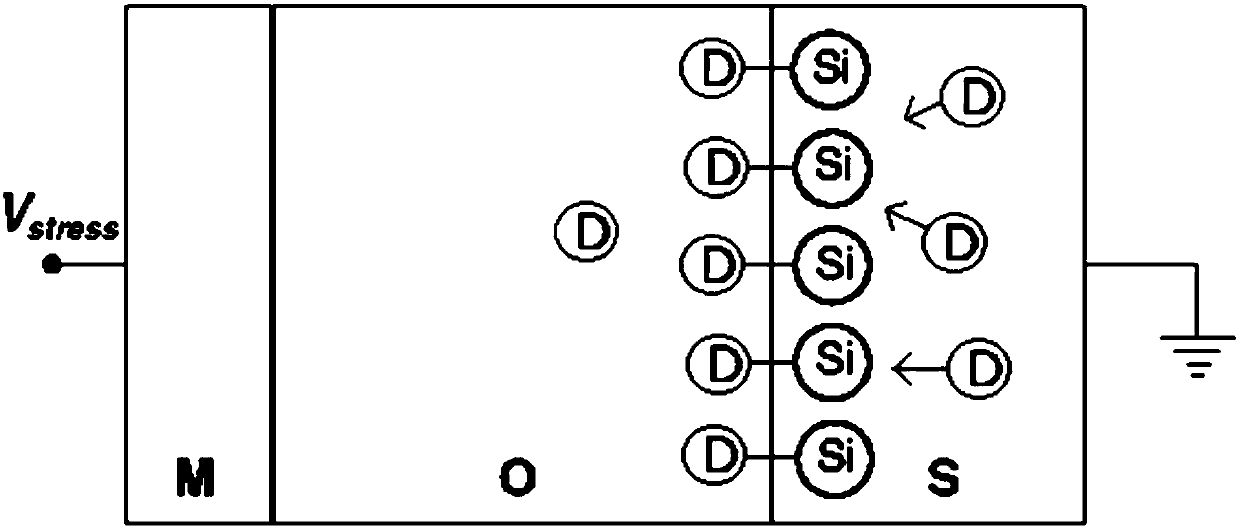

[0053] Such as Figure 4 As shown, this embodiment provides a method for Czochralski growth of single crystal silicon, the basic steps of which are as in embodiment 1, wherein, the difference from embodiment 1 is that in step 1) S21, the deuterium, nitrogen and The preparation steps of the barium-doped silicon chip include: performing ion implantation doping on the silicon chip with deuterium ions, nitrogen ions and barium ions by ion implantation method to form the silicon chip doped with deuterium, nitrogen and barium. In this embodiment, the deuterium ions, nitrogen ions and barium ions may be implanted into the silicon wafer sequentially, or may be implanted into the silicon wafer at the same time. Wherein, the implantation energy range of the deuterium ions is 1keV-1000keV, and the dose is 1E12-1E18ions / cm 2 , the implantation energy range of the nitrogen ions is 1keV-1000keV, and the dose is 1E12-1E18ions / cm 2 , the implantation energy range of the barium ions is 1keV~...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com