Graphite loaded tin dioxide electrode and preparation method

A tin dioxide and electrode technology, which is applied in chemical instruments and methods, liquid chemical plating, water/sludge/sewage treatment, etc., can solve problems such as hindering application and poor conductivity, and achieve improved structure and properties, and improved Electrode performance, effect of large free space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A graphite-supported tin dioxide electrode and a preparation method thereof, specifically comprising the following steps:

[0029] A. Graphite sheets (fixed carbon content > 99%) of 10cm × 10cm are used in turn with 100 # , 300 # and 500 # Grinding with sandpaper, removing the surface inert layer, making the surface of the substrate smooth, then ultrasonically cleaning in distilled water and acetone for 20 minutes, then cleaning twice with distilled water, cleaning and drying; immerse the cleaned graphite sheet in aqua regia, boil 1h, carry out the oxygen termination treatment, wait for the aqua regia to cool naturally, take out the graphite sheet and wash it twice with distilled water, dry it after cleaning; then place the graphite sheet in the muffle furnace, in the carbon dioxide atmosphere, use the temperature program to carry out Heat treatment, the program temperature is 1°C / min, the hole expansion heat treatment temperature is 600°C, and the heat treatment time...

Embodiment 2

[0036] A graphite-supported tin dioxide electrode and a preparation method thereof, specifically comprising the following steps:

[0037] A. Graphite sheets (fixed carbon content > 99%) of 10cm × 10cm are used in turn with 100 # , 300 # and 500 # Grinding with sandpaper, removing the inert layer on the surface, making the surface of the substrate smooth, then ultrasonically cleaning in distilled water and acetone for 20 minutes, washing twice with distilled water, and drying after cleaning; soaking the cleaned graphite sheet in 65% nitric acid for 24 hours , carry out oxygen termination treatment, take out the graphite sheet and wash it twice with distilled water, dry it after cleaning; then place the graphite sheet in a muffle furnace, and heat-treat it in a carbon dioxide atmosphere by using a temperature program at a temperature of 5°C / min, the hole expansion heat treatment temperature is 800°C, and the heat treatment time is 5h to obtain a spare graphite sheet;

[0038...

experiment example

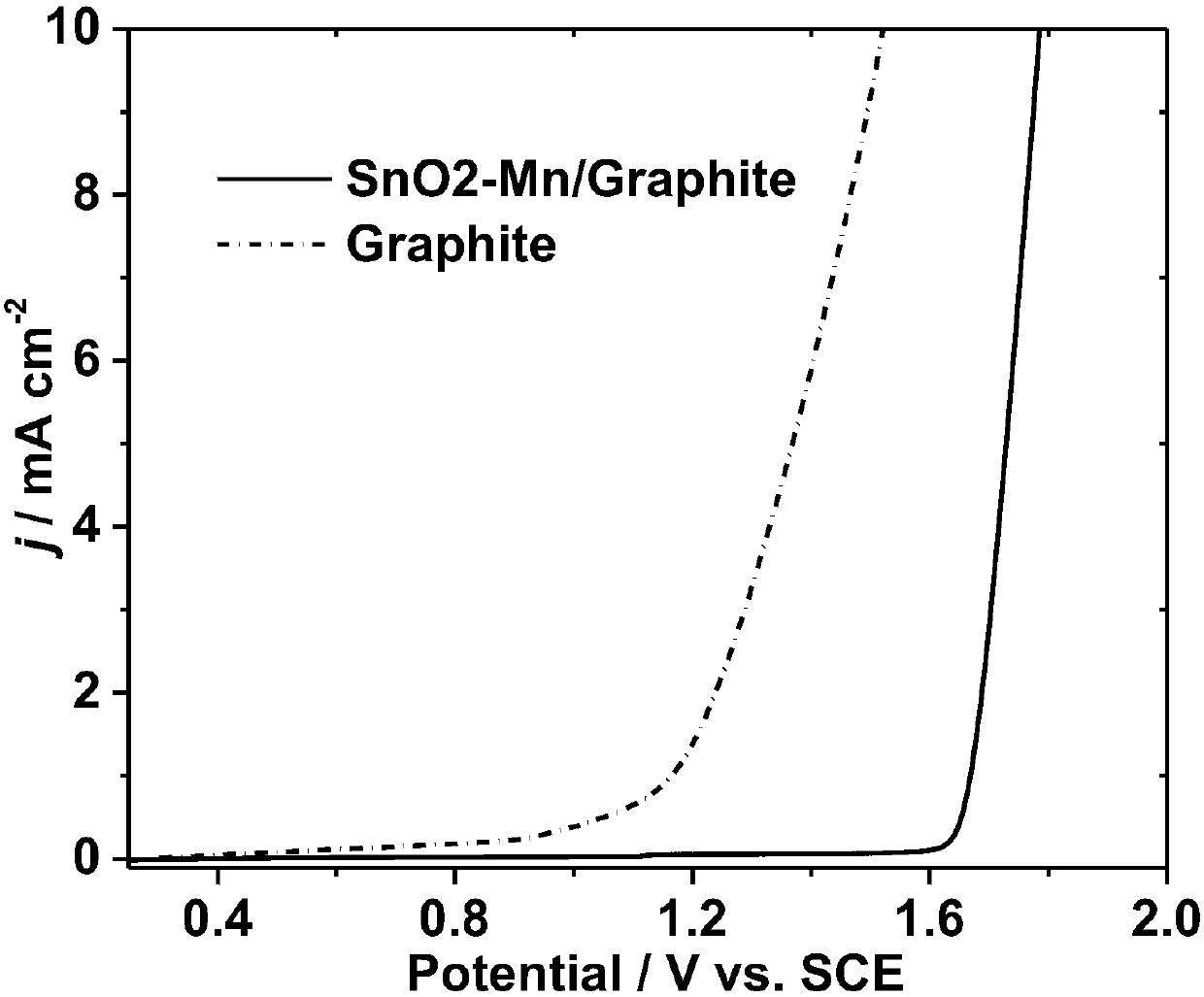

[0041] Adopt the SnO that embodiment 1 prepares 2 -Mn / Graphite Electrode Electrocatalytic Oxidation Degradation of High Concentration Pesticide Wastewater. The electrocatalytic degradation is carried out in a single-cell circular electrochemical reaction cell, and a cup with circulating water is added to keep the temperature of the reaction system at room temperature. The prepared electrode is used as the anode, the Ti plate is used as the counter electrode, and the electrode area is 100 cm 2 , electrochemical degradation using constant current electrolysis, constant current density 100mA cm -2 . COD containing 3% NaCl electrolyte cr The value is 750mg / L. The treated water after electroplating is a wastewater sample, and the reaction volume is 500ml. Samples are taken at different times during the degradation reaction for analysis. Sampled COD cr The value is determined by potassium dichromate standard method (GB11914-89).

[0042] The results showed that the removal rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com