Molding sands for glass matrix casting

A molding sand and matrix technology, which is applied in the field of casting sand and glass matrix casting sand, can solve the problems of low air permeability, no compressibility, and poor yield of molding sand, and achieve simple, convenient, high-purity and clean sand mixing process High degree, good effect of reuse and regeneration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

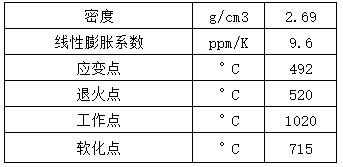

[0031] Embodiment 1: The making of raw sand: with the recovered CRT equipment as raw material, use a glass cutting machine to separate the glass screen and the glass cone of the CRT from the screen cone seal, remove the nails and the shadow mask on the glass screen, and place the The glass screen is put into the jaw crusher for coarse crushing, and the coarsely broken glass block is put into the fine grinder for fine crushing. Here, the fine grinder can be a compound crusher or a hammer crusher. The finely crushed screen glass has an aperture of 3mm for vibration Sieve, take the undersieve and put it into the screw mixer to perform the mixing program for 5 minutes. After the mixing is completed, the glass particles pass through a 2mm vibrating sieve and a 300um vibrating sieve, and take the 300um vibrating sieve to obtain the original sand; this embodiment In the process, a mixer is used to round the glass particles. Because the glass itself is hard, the glass particles collide...

Embodiment 2

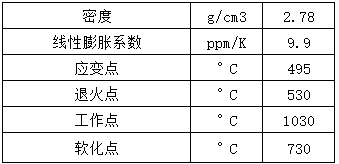

[0038] Embodiment 2: The making of raw sand: with the recovered CRT equipment as raw material, use glass cutting machine to separate the glass screen and glass cone of CRT from the screen cone seal, remove the nails and shadow mask on the glass screen, and place The glass screen is put into the jaw crusher for coarse crushing, and the coarsely broken glass block is put into the fine grinder for fine crushing. Here, the fine grinder can be a compound crusher or a hammer crusher. The aperture of the finely crushed screen glass is 1.5mm. After the vibrating sieve, take the sieved material and put it into the beading furnace. The main body of the beading furnace is a vertical cylinder. A burner is installed at the lower part of the vertical cylinder. Put into the vertical cylinder, the glass powder floats in the upward high-temperature airflow generated by the burner, and is heated and melted to form microbeads during the rising process. The microbeads enter the product collection ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| angle factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com