Method and system for preparing propylene by oxidative dehydrogenation of chemical chain propane

A chemical chain propane, oxidative dehydrogenation technology, applied in the field of chemical chain propane oxidative dehydrogenation to prepare propylene, can solve the problems that are not conducive to the safe operation of equipment, complicated production process, lower propylene yield, etc., and achieve the elimination of the limitation of thermodynamic equilibrium , good product quality, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

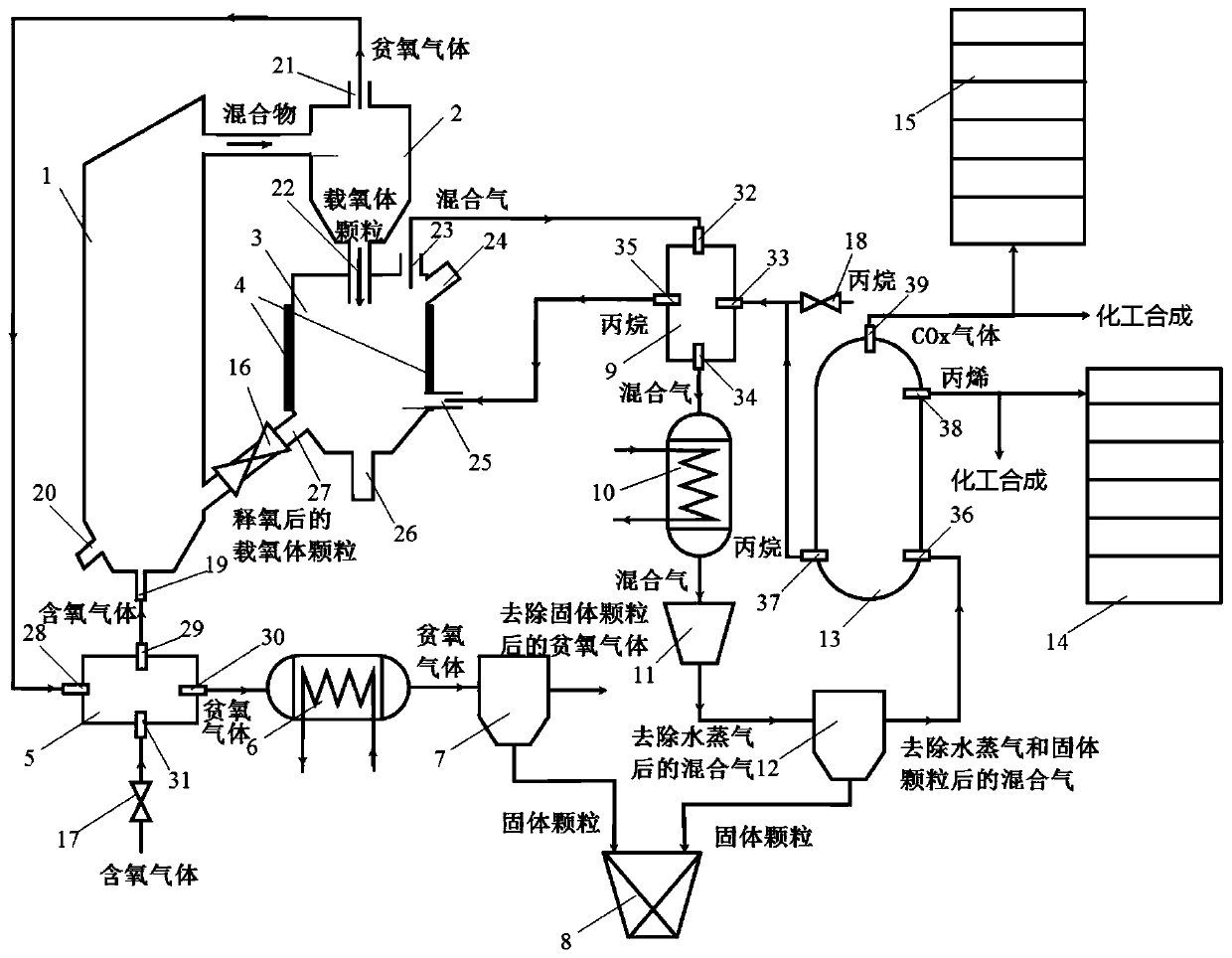

[0030] refer to figure 1 , this embodiment provides a system for preparing propylene by oxidative dehydrogenation of chemical chain propane, the system includes a dehydrogenation reactor 3, a mixed gas purification device, a mixed gas separation device 13, an oxidation reactor 1, a mixed gas heat exchanger 9, Mixed gas waste heat boiler 10 , oxygen-lean gas heat exchanger 5 , oxygen-lean gas waste heat boiler 6 , oxygen-lean gas dust collector 7 , separation equipment 2 , hopper 8 , COx gas storage 15 and propylene storage 14 .

[0031] The dehydrogenation reactor 3 can receive propane and oxygen carrier particles, and provide propane and oxygen carrier particles to react therein at high temperature to generate propylene, water vapor, COx gas and oxygen carrier particles after oxygen loss, COx gas As a by-product of the reaction of propane with oxygen carrier particles. The propylene and water vapor generated by the oxidative dehydrogenation reaction and the water vapor and C...

Embodiment 2

[0081] This embodiment provides a method for preparing propylene by oxidative dehydrogenation of chemically chained propane. The method uses the system of the above-mentioned embodiment 1 and includes the following steps:

[0082] S1. Pass propane into the dehydrogenation reactor 3, and a part of propane and oxygen carrier particles undergo oxidative dehydrogenation reaction at high temperature (preferably 300-700°C) to generate propylene, water vapor and oxygen carrier after deoxygenation Granules, another part of propane in the dehydrogenation reactor 3 undergoes a deep oxidation reaction at high temperature to generate water vapor and COx gas. The mixed gas containing propylene and water vapor generated by the oxidative dehydrogenation reaction, water vapor and COx gas generated by the deep oxidation reaction, and incompletely reacted propane, and the oxygen carrier particles after deoxygenation are output from the dehydrogenation reactor 3 respectively To the mixed gas hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com