Preparation method and product of red blood cell-shaped hollow carbon

A technology of red blood cells and hollow carbon, which is applied in the preparation/purification of carbon, structural parts, electrical components, etc., can solve the problems of high cost, poor cycle stability, low specific capacity of secondary batteries, etc., and achieve the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

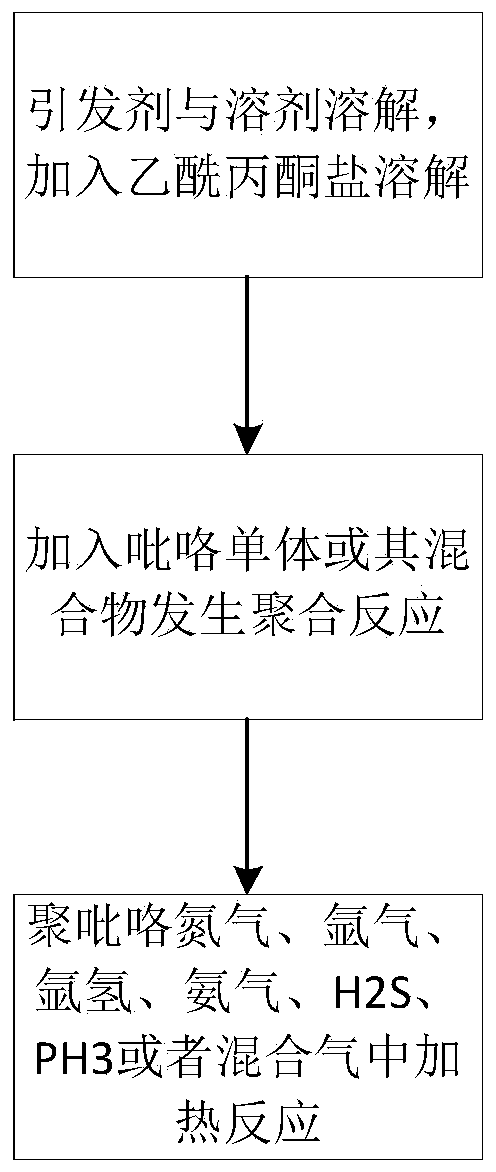

[0032] figure 1 It is a flow chart of the preparation method of red blood cell-shaped hollow carbon constructed according to a preferred embodiment of the present invention, such as figure 1 As shown, a method for preparing red blood cell-shaped hollow carbon includes the following steps:

[0033] Step 1: Disperse the initiator in a solvent, the solvent is deionized water or a mixed solution of ethanol and deionized water, stir evenly to obtain the first mixture A;

[0034] Among them, the molar ratio of initiator to solvent is 0.001-20:1, when the molar ratio is 0.1-5:1, the effect is better; the initiator can be an azo initiator (such as azobisisobutyronitrile), H 2 O 2 , Benzoyl, nitric acid, persulfate (such as ammonium persulfate), FeCl 3 One or more of etc;

[0035] Step 2: Add a certain amount of acetylacetonate to the first mixture A and stir evenly to obtain the second mixture B;

[0036] Among them, the concentration of acetylacetonate relative to the solvent is 3g / L~100g / L;...

preparation Embodiment 1

[0049] In the first step, 15ml of concentrated nitric acid was dispersed in 30ml of deionized water and stirred to obtain solution A; in the second step, 0.3g of molybdenum acetylacetonate was added to solution A and stirred in a magnetic stirrer until it was dissolved to obtain solution B; The third step is to add 100ul pyrrole monomer to the solution B, and let it stand at 20°C for 24h, the solid product obtained is centrifuged, washed, and dried to obtain solid C; the fourth step, product C is placed in the tube The carbonization process is carried out in the furnace, and the temperature is raised to 800°C at a heating rate of 1.5°C / min under an argon atmosphere, and the temperature is kept for 2 hours, and then naturally cooled to room temperature, and finally a nitrogen-doped red blood cell-like hollow carbon material is obtained.

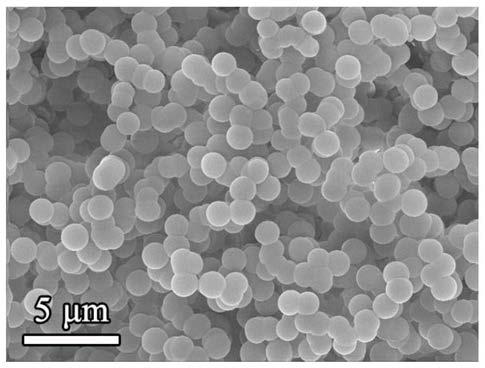

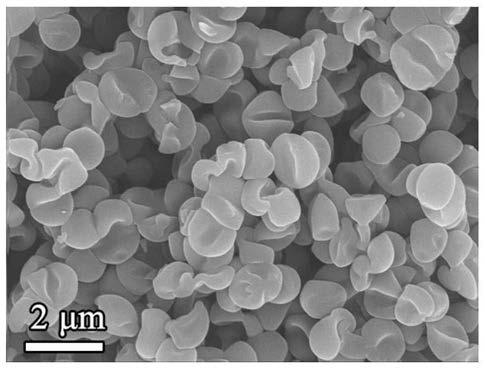

[0050] figure 2 It is a scanning electron microscope (SEM) image of the polypyrrole sphere precursor prepared in the preferred embodiment 1 cons...

preparation Embodiment 2

[0052] The first step is to add 10ml of H 2 O 2 Disperse in 200ml of deionized water and stir evenly to obtain solution A; in the second step, add 0.3g of iron acetylacetonate and 0.3g of molybdenum acetylacetonate to solution A, stir in a magnetic stirrer until dissolved, to obtain solution B; In the third step, 200uL pyrrole monomer was added to the solution B and allowed to stand at 30°C for 0.5h. The solid product obtained was centrifuged, washed, and dried to obtain solid C; in the fourth step, product C was placed in a tube furnace Carrying out carbonization treatment, raising to 1400°C at a heating rate of 1°C / min under a nitrogen atmosphere, and keeping the temperature for 1 min, and then naturally cooling to room temperature, finally obtaining a red blood cell-like hollow carbon material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com