Cofactor regeneration mycobacteria and its application in fermentation of oil-water two-liquid phase

A new mycobacterium aureus, two-liquid phase technology, applied in the field of biocatalysis, can solve the problems of low substrate solubility, slow metabolism of phytosterols, slow metabolism of strains, etc., and achieve the effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The construction of embodiment 1 recombinant bacterial strain MNR M3N2

[0026] 1. Construction of pMV261-nox-2 plasmid, the process includes:

[0027] (1) Synthesize the target gene, according to the nucleotide sequence (Gene ID: 13019046, SEQ ID NO.1) of the NZ9000 NADH oxidase gene nox-2 of Lactococcus lactis subsp. (BamH I and Sal I) were added to both ends of the nox-2 sequence, and the designed sequence was handed over to Jinweizhi Company for gene synthesis;

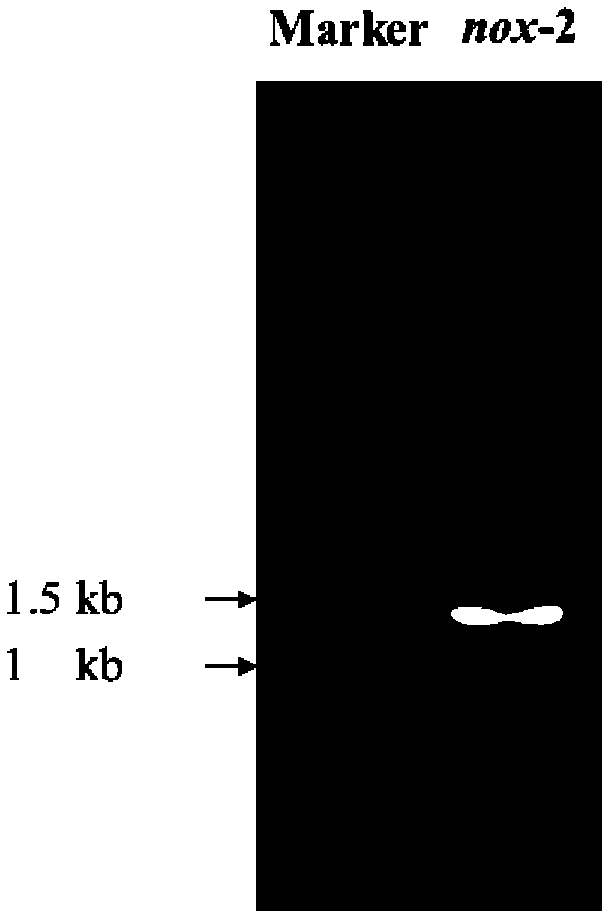

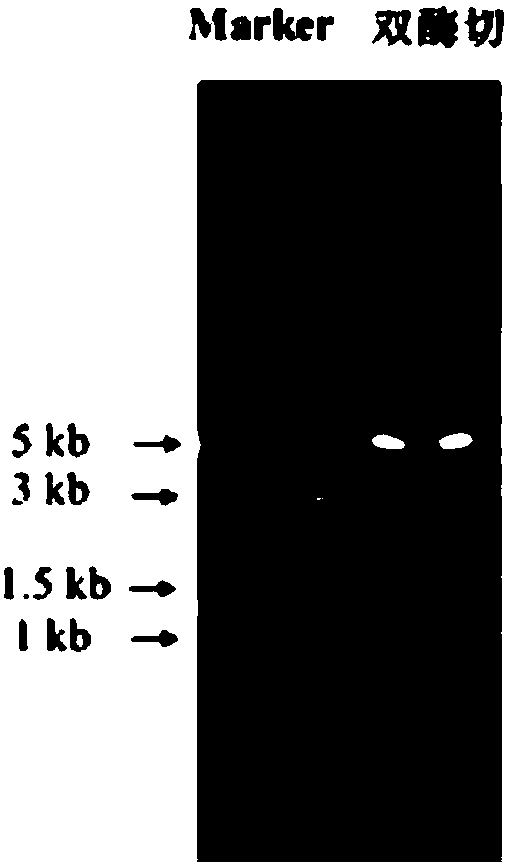

[0028] (2) PCR amplification of the target gene fragment nox-2 gene (the verification picture is figure 1 ), the target fragment nox-2 and the expression plasmid pMV261 were digested with BamHI and SalI respectively, purified and ligated to obtain the recombinant plasmid pMV261-nox-2.

[0029] 2. Construction of strain MNR M3N2:

[0030] (1) Preparation of Mycobacterium MNR M3 Competent Cells: Primary Seed Culture to OD 600 1.0, according to 10% inoculum amount transferred to the seed medium for seconda...

Embodiment 2

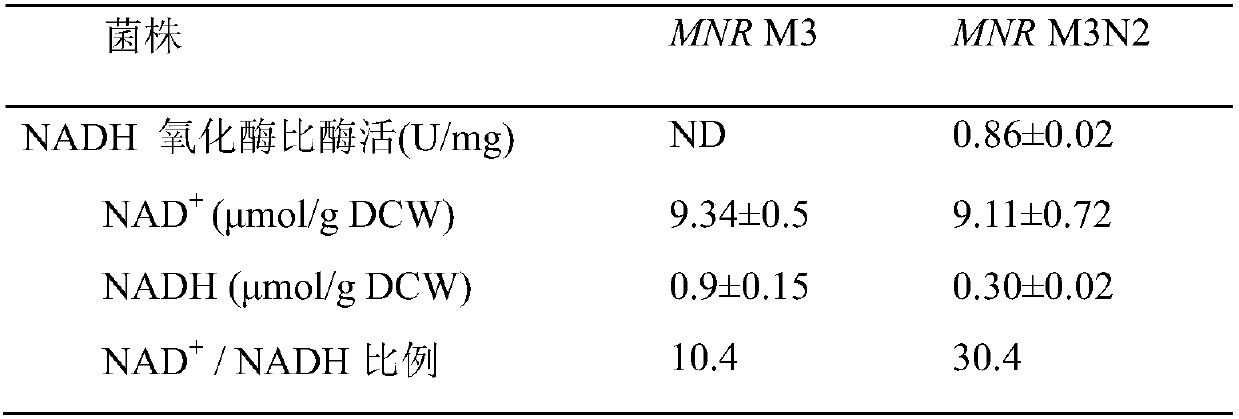

[0034] NAD (H) content and NAD in the recombinant bacterium MNR M3N2 of embodiment 2 + / NADH ratio comparison.

[0035] 1. Bacteria activation culture:

[0036] Transfer the recombinant bacteria MNR M3N2 and the original bacteria MNR M3 to fresh slant medium, culture at 29°C for 2-4 days, wash the strains on the slant medium with 20mL 0.5% Tween 80 sterile aqueous solution to obtain the eluate, Take 1mL of the eluate and add it to 30mL of the seed medium, and culture it on a shaker at 29°C and 200r / min for 36h to obtain the seed solution;

[0037] Slant medium composition: K 2 HPO 4 0.5g / L, MgSO 4 ·7H 2 O 0.5g / L, ferric ammonium citrate 0.05g / L, citric acid 2g / L, ammonium nitrate 2g / L, glycerin 20g / L, glucose 5g / L, CaCO 310g / L, agar 20g / L, the rest is water, pH7.2;

[0038] Seed medium composition: K 2 HPO 4 0.5g / L, MgSO 4 ·7H 2 O 0.5g / L, ferric ammonium citrate 0.05g / L, citric acid 2g / L, ammonium nitrate 2g / L, glycerin 20g / L, glucose 5g / L, CaCO 3 10g / L, the res...

Embodiment 3

[0056] Example 3 The MNR M3N2 strain catalyzes the production of androstenedione from phytosterols in an aqueous phase system

[0057] 1. Bacteria activation culture:

[0058] Transfer the recombinant bacteria MNR M3N2 and the original bacteria MNR M3 to fresh slant medium respectively, culture at 29°C for 3 days, wash the bacteria on the slant medium with 20mL 0.5% Tween 80 sterile aqueous solution, and mix them evenly to elute solution, absorb 1mL of the eluent and add it to 30mL of the seed medium, and culture it on a shaking table at 29°C and 200r / min for 36h to obtain the seed culture solution;

[0059] Slant medium composition: K 2 HPO 4 0.5g / L, MgSO 4 ·7H 2 O 0.5g / L, ferric ammonium citrate 0.05g / L, citric acid 2g / L, ammonium nitrate 2g / L, glycerin 20g / L, glucose 5g / L, CaCO 3 10g / L, agar 20g / L, the rest is water, pH7.2;

[0060] Seed medium composition: K 2 HPO 4 0.5g / L, MgSO 4 ·7H 2 O 0.5g / L, ferric ammonium citrate 0.05g / L, citric acid 2g / L, ammonium nitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com