Device and process for producing acetaminophen

A technology of acetaminophen and bulk packing, applied in the field of chemical engineering, can solve the problems of many by-products, product oxidation, long reaction time, etc., and achieve the effect of improving reaction efficiency and reducing by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

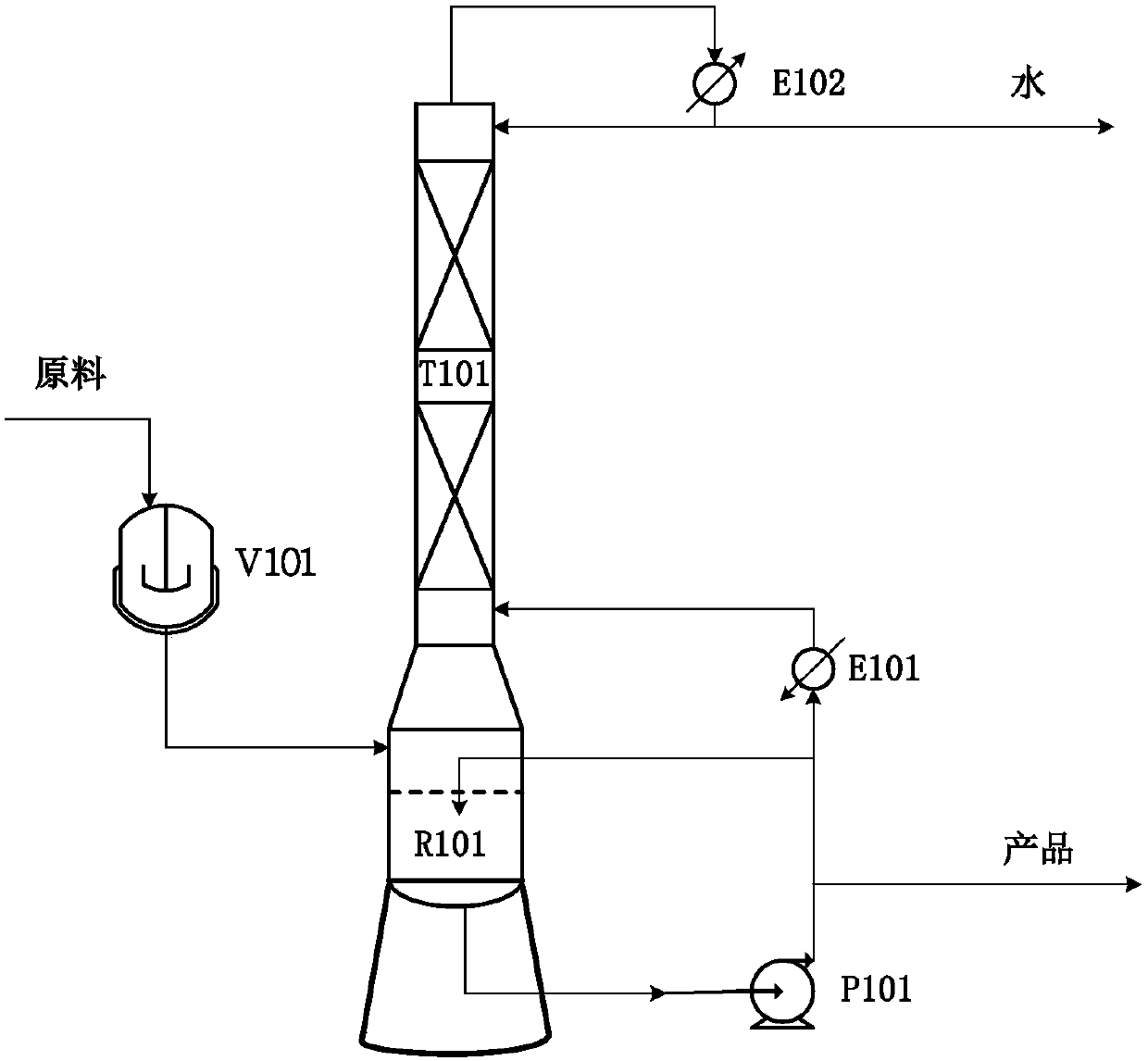

[0038] Such as figure 1 As shown, a certain enterprise produces a reactive distillation device for acetaminophen, including a split reaction section R101 and a rectification section T101, as well as a condenser E102 and a heat exchanger E101,

[0039] The reaction section R101 is hermetically connected below the rectification section T101,

[0040] Trays are arranged in the rectification section T101, and random packing is arranged below the trays or rectification packings, and a production port and a return port are provided at the top of the rectification section T101, and the production port passes through the The condenser E102 is respectively connected to the return port and the condensation outlet,

[0041] The reaction section R101 is an intensified reactor, the reaction section R101 is provided with a raw material inlet, a circulation outlet and a circulation inlet, the circulation outlet is connected to the inlet of the circulation pump, and the outlet of the circula...

Embodiment 2

[0053]This embodiment 2 adopts the same reactive distillation device as that of embodiment 1. The only difference is that the rectification section is filled with condensate packing; when calculating the distance between the reaction section and the rectification section, the passage time is 0.5 seconds; the diameter of the bottom ceramic ball of the random packing is 15 mm, and The diameter of the layer of ceramic balls is 7 mm, and the diameter of the uppermost layer of ceramic balls is 3 mm; the distance between the bulk packing and the condensed packing is 20 cm.

[0054] During production, the reaction materials p-aminophenol and acetic acid are heated, stirred, dissolved and mixed in the stirring mixing tank V101, and then enter the micro-interface strengthening reactor R101 through the pipeline for reaction, and the reaction materials are circulated through the circulation inlet under the action of the circulation pump , the material heated by the heat exchanger E101 is...

Embodiment 3

[0056] This embodiment 3 adopts the same reactive distillation device as that of embodiment 1. The only difference is that when calculating the distance between the reaction section and the rectification section, the passage time is 0.8 seconds; the diameter of the bottom layer of ceramic balls of random packing is 20 mm, and the diameter of the middle layer of ceramic balls is 8 mm. The diameter of the uppermost layer of ceramic balls is 4 mm; the distance between bulk packing and condensed packing is 30 cm.

[0057] During production, the reaction materials p-aminophenol and acetic acid are heated, stirred, dissolved and mixed in the stirring mixing tank V101, and then enter the micro-interface strengthening reactor R101 through the pipeline for reaction, and the reaction materials are circulated through the circulation inlet under the action of the circulation pump , the material heated by the heat exchanger E101 is vaporized and returned to the reactive distillation device...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com