Preparation method of boron nitride fiber three-dimensional structure material and product of boron nitride fiber three-dimensional structure material

A boron nitride fiber and three-dimensional structure technology, applied in the field of ceramic materials, can solve the problems of limited application range, complex reaction and process conditions, and limited high temperature resistance of boron nitride

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

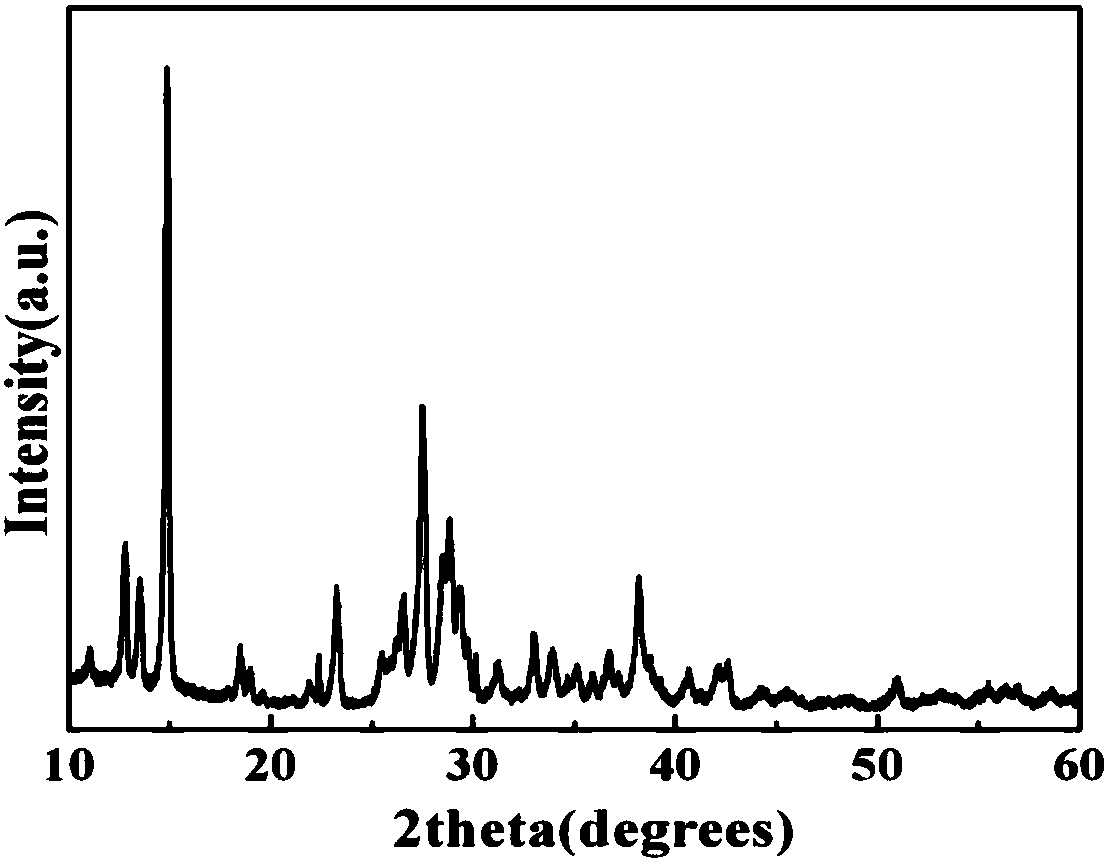

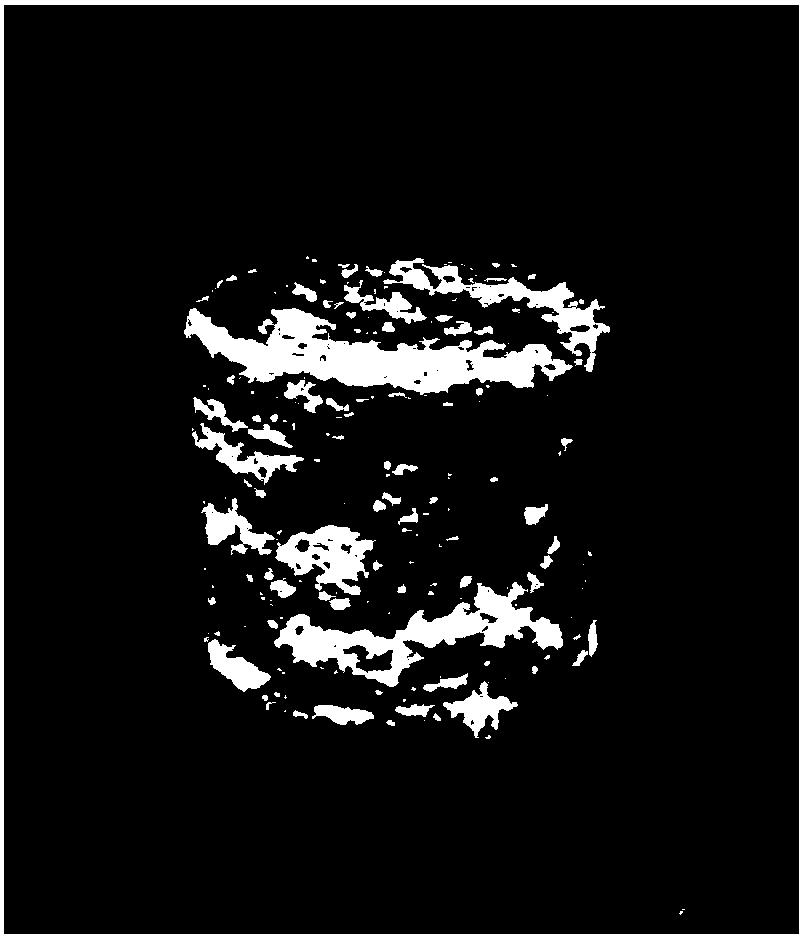

[0058] S1. Synthetic fibrils: add melamine and boric acid to deionized water, add 1.26 grams of melamine and 1.86 grams of boric acid per 100 ml of deionized water, the molar ratio of the two is 1:3, put the system into a water bath at 85 ° C and heat and stir Continue to heat and stir for 30 minutes until the solute is completely dissolved to form a colorless transparent solution; then cool it at 30°C to precipitate a precipitate, and after standing for 24 hours, filter to obtain a solid precipitate and dry it at a constant temperature of 50°C Insulated in the box for 24 hours, a white solid after drying was obtained, figure 1 The scanning electron microscope image shows that it is a fiber morphology, figure 2 The X-ray diffraction pattern shows that its structure is C 3 N 6 h 6 2H 3 BO 3 Molecular crystal, namely M·2B;

[0059] S2. Fibril three-dimensional structure forming: add dry M·2B fibrils to deionized water, add 10.0 grams of fibrils per 100 ml of deionized wa...

Embodiment 2

[0065] S1. Synthetic fibrils: Add melamine and boric acid to water, add melamine and boric acid to water, add 1.26 grams of melamine and 1.24 grams of boric acid per 100 ml of water, the molar ratio of the two is 1:2, put the system in a water bath at 80 °C Heat and stir at medium temperature until the solute is completely dissolved, continue to heat and stir for 10 minutes, and form a colorless transparent solution; then place it at 20°C to cool, and a precipitate precipitates, after standing for 10 hours, filter to obtain a solid precipitate, and place in 80 ℃ in a constant temperature drying oven for 5 hours to obtain dried white M·2B fibrils;

[0066] S2. Fibril three-dimensional structure forming: add dry M·2B fibrils to water, add 5.0 grams of fibrils per 100 ml of water, keep stirring in a water bath at 50°C for 0.5 hours to form a fluid slurry, and pour it into In a cylindrical mold, cool at 20°C and let it stand for 24 hours, then freeze it with liquid nitrogen at -80...

Embodiment 3

[0070] S1. Synthetic fibrils: add melamine and boric acid to deionized water, add 2.52 grams of melamine and 6.20 grams of boric acid per 100 ml of water, the molar ratio of the two is 1:5, put the system into a 95 ° C water bath and heat and stir until the solute Dissolve completely, continue to heat and stir for 30 minutes to form a colorless and transparent solution; then place it at room temperature at 30°C to cool, precipitate precipitates, and after standing for 24 hours, filter to obtain solid precipitates, and place them in a constant temperature drying oven at 60°C Insulated for 15 hours to obtain a dried white solid, i.e. M·2B fibrils;

[0071]S2. Fibril three-dimensional structure forming: add dry M·2B fibrils to water, add 22.5 grams of fibrils per 100 ml of water, heat and stir for 5 hours in a water bath at 95°C to form a fluid slurry, and pour it into In a cylindrical mold, cool at 25°C and let it stand for 24 hours, then put it in the refrigerator to freeze for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com