Method for high-efficiency and high-density culture of biological bait

A technology of high-density cultivation and biological bait, which is applied in the field of high-efficiency and high-density cultivation of biological bait, can solve the problems of high harvesting cost, low density of algae cells, and unbalanced nutrients, so as to reduce production costs, simplify the process flow, and ensure effect of homogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

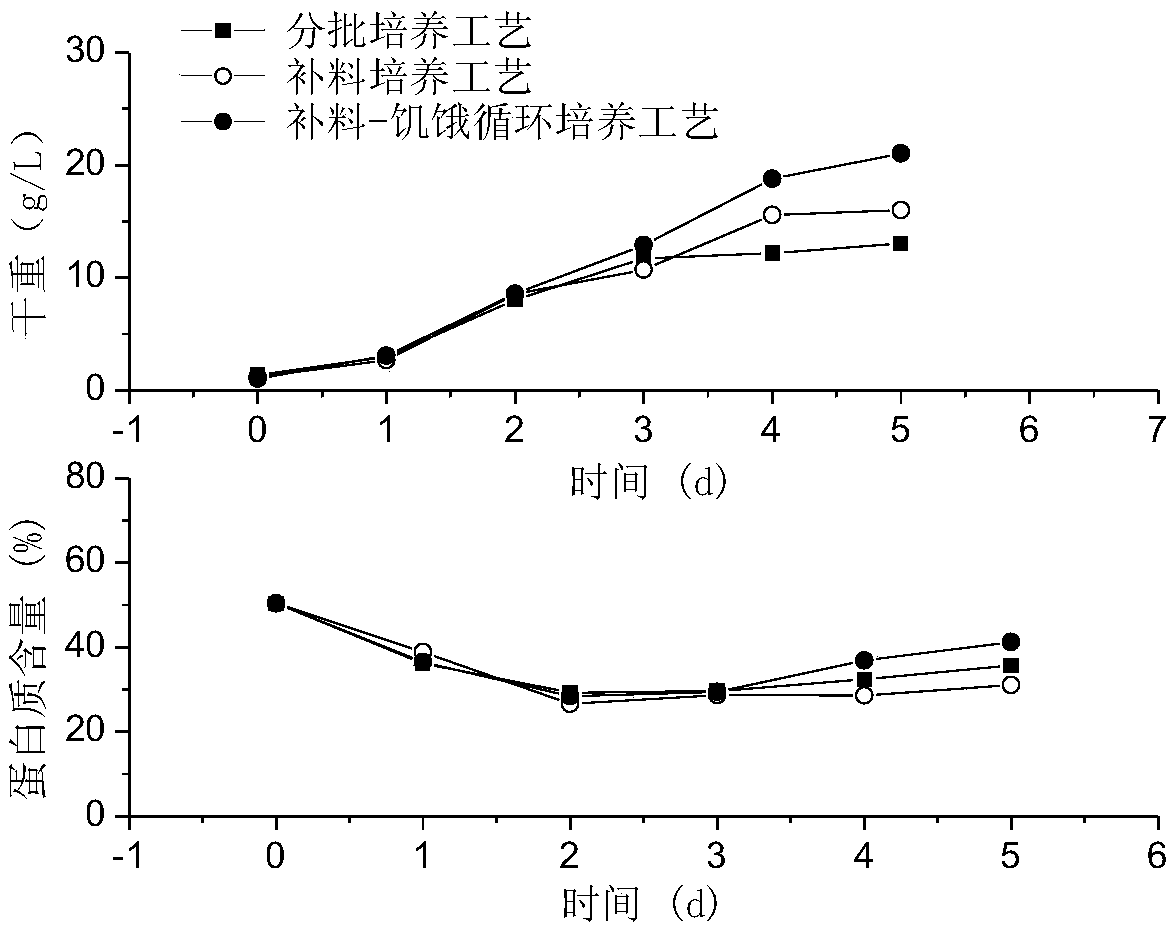

[0069] Add 250ml of basal medium into a 500ml shake flask (recipe is shown in Table 1), insert the algae cells that have been checked for sterility and normal appearance into the shake flask for culture, the culture conditions are: completely dark culture, and the culture temperature is 30°C , the initial speed is 150rpm. The experimental design was divided into 3 groups:

[0070] Experiment 1 (batch culture process): Batch culture was used to culture without supplementing the basal medium concentrate.

[0071] Experiment 2 (feed-fed culture process): Firstly, the batch culture method was used to culture, and the basal medium concentrate was supplemented every 12 hours from the 3rd day of culture.

[0072] Experiment 3 (feed-starvation cycle culture process): Firstly, the batch culture method was used to culture, and the basal medium concentrate was supplemented every 24 hours from the 3rd day of culture.

[0073] Samples were taken at regular intervals to determine cell dry...

Embodiment 2

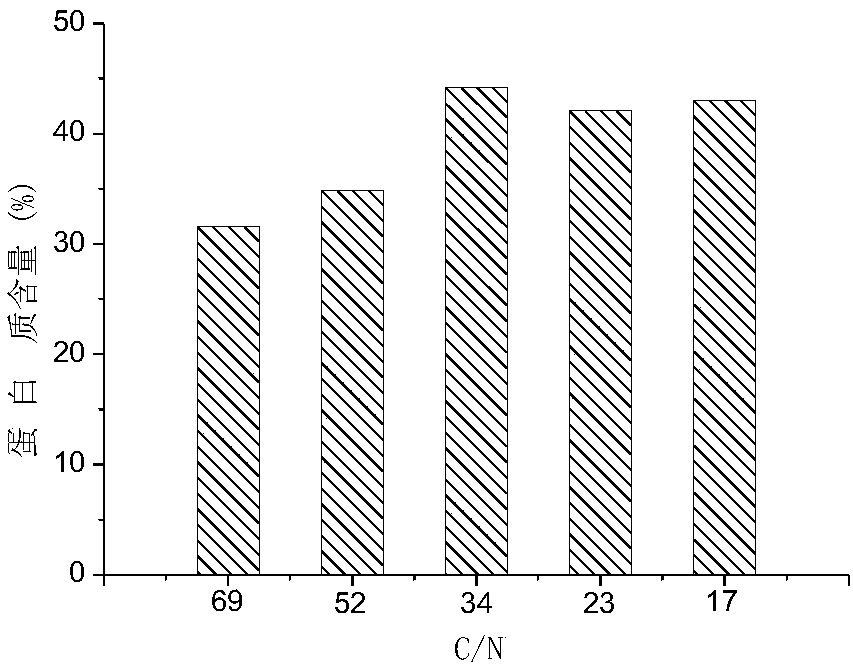

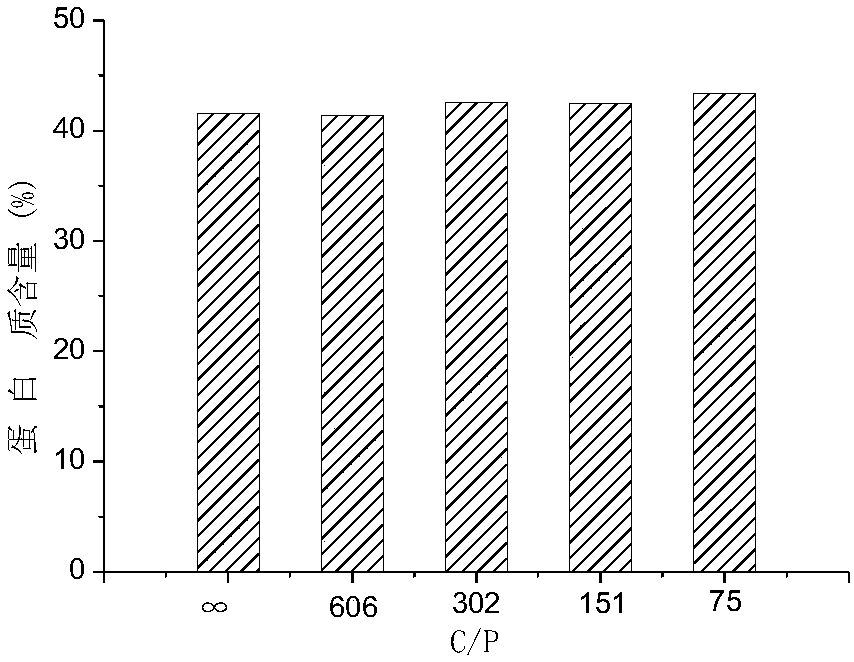

[0081] Add 250ml of basal medium into a 500ml shake flask (recipe is shown in Table 1), insert the algae cells that have been checked for sterility and normal appearance into the shake flask for starvation culture for 16 hours, and the culture conditions are: completely dark culture, culture temperature is 30°C, initial rotation speed 150rpm. The C / N ratio is set to: 69, 52, 34, 23, 17. The C / P ratio is set to: ∞, 606, 302, 151, 75. Samples were taken at regular intervals to determine cell dry weight, protein content, glucose content, nitrate content and phosphate content.

[0082] Phosphate content was determined by molybdenum acid spectrophotometry (GB / T 11893-1989 Determination of total phosphorus in water quality by ammonium molybdate spectrophotometry).

[0083] Analysis of results: by figure 2 It can be seen that too low nitrogen concentration affects the accumulation of intracellular protein in Chlorella cells, mainly because there is a certain threshold for the act...

Embodiment 3

[0085] Add basal culture medium (recipe is shown in Table 2) in the bioreactor, and the filling factor of the reactor is 70%, inserts the algae cell that checks sterility and normal appearance state into the bioreactor to cultivate, and the culture condition is: culture temperature The temperature is 30°C, the gas-liquid ratio is 1.0vvm, and the initial rotation speed is 200rpm. When Do<20%, the rotation speed increases by 50rpm, and the maximum rotation speed is 1000rpm. The experimental design is divided into 2 groups:

[0086] Experiment 1 (feed-feeding process): First, batch culture was used to cultivate Chlorella, and when the cell density reached a certain value (ie, glucose<20g / L), fed-feed medium was added (see Table 3 for the formula).

[0087] Experiment 2 (feed-starvation cycle culture process): Firstly, the batch culture method was used to cultivate Chlorella, and when the cell density reached a certain value (i.e. glucose <20g / L), fed-batch feeding medium (recipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com