Method for improving enzymolysis saccharifying efficiency of hemp straw

A technology for saccharification efficiency and hemp, which is applied in the field of enzymatic hydrolysis of hemp stalks promoted by the combined use of microorganisms and alkaline hydrogen peroxide, can solve the problems of low efficiency of direct enzyme treatment, shorten pretreatment time, improve swelling effect, and increase yield The effect of the amount of reducing sugar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

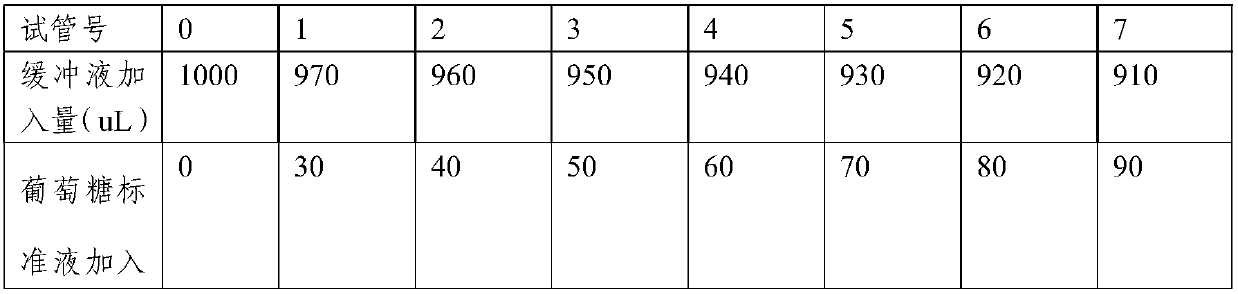

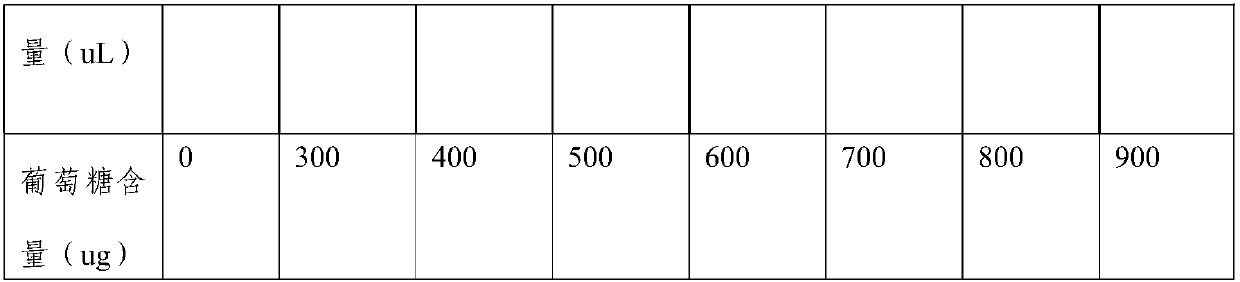

[0048] This embodiment relates to a method for enzymatic hydrolysis of hemp straw, which mainly includes the following steps:

[0049] A. Pretreatment of hemp straw

[0050] 1) Crush hemp straw (ramie, hemp or kenaf) to 200 mesh, adjust the water content to 70% after high-temperature sterilization, mix according to the volume-to-mass ratio of the bacterial solution to the hemp straw at 1:10, and inoculate it for activation After cultivating the Pleurotus eryngii bacteria liquid for 21 days at 28° C., the cultured mixture was extracted at normal temperature with a citric acid-sodium citrate buffer solution with a pH of 4.8, filtered, and the filter residue was dried to a constant weight. Obtain hemp straw after biological pretreatment;

[0051] 2) Mix the biologically pretreated hemp straw with a mixed solution of sodium hydroxide and hydrogen peroxide at a mass volume ratio of 1:20, treat at 40°C for 24 hours, filter, wash the filter residue with distilled water until neutral...

Embodiment 4

[0056] Using ramie straw as a raw material, compared with Example 1, the difference is that in step 1), the straw is treated with Phanerochaete chrysosporium. After testing, the reducing sugar content of ramie straw was 159 mg / g.

Embodiment 5

[0058] Using ramie stalks as raw materials, compared with Example 1, the difference is that in step 1), the stalks are treated with Pleurotus ostreatus. After testing, the reducing sugar content of the ramie straw was 376 mg / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com