Method for preparing optical pure L-tertiary leucine from active inclusion body

A technology of tert-leucine and inclusion bodies, applied in the field of bioengineering, to achieve the effects of simple process flow, reduced production cost, and easy separation and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Construction of FDH-LeuDH Bifunctional Enzyme Recombinant Strain

[0044] Overlap extension polymerase chain reaction (OE-PCR) was used to construct the FDH-LeuDH fusion enzyme mediated by different connecting peptides, and the construction of the FDH-R1-LeuDH fusion enzyme gene was taken as an example to describe the construction process. First, design primers based on LeuDH, FDH, connecting peptide sequence and restriction site on pET28a plasmid:

[0045] P1: 5'-GGAATTC CATATG AAAATTGTCCTGGTCCTGT-3' (SEQ ID NO 05), the underline is the NdeI restriction site sequence.

[0046] Connecting peptide primers:

[0047] 5’-GCCTATGGCAAACACGATAAAAAG XXX ATGACATTGGAAATCTTCGA-3', XXX refers to the connecting peptide sequence, see Table 1 for details.

[0048] P3: 5'-ATGACATTGGAAATCTTCGAATAT-3' (SEQ ID NO 06).

[0049] P4: 5'-CCG CTCGAG TTACCGGCGACTAATGATGT-3' (SEQ ID NO 07), the underline is the XhoI restriction site sequence.

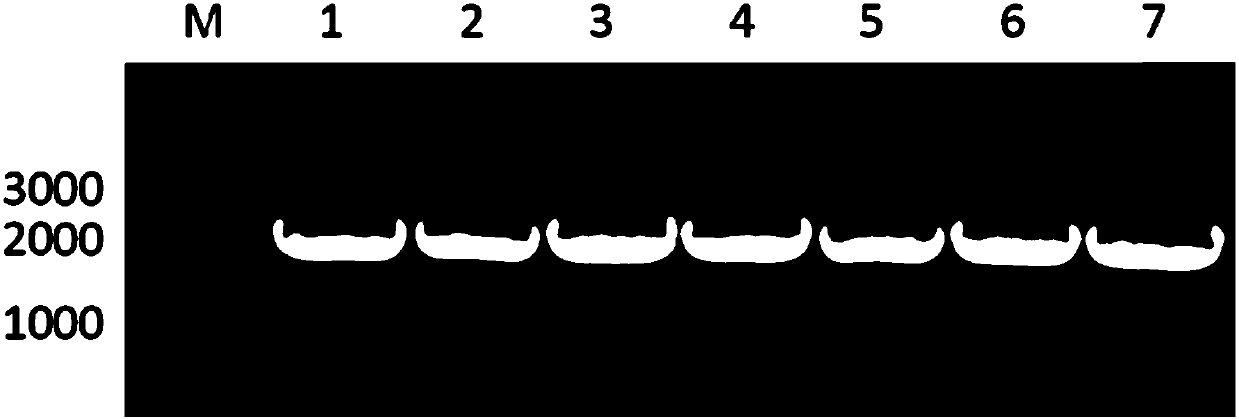

[0050] Using FDH and LeuDH genes as templ...

Embodiment 2

[0058] Preparation of Bifunctional Enzyme Active Inclusion Body

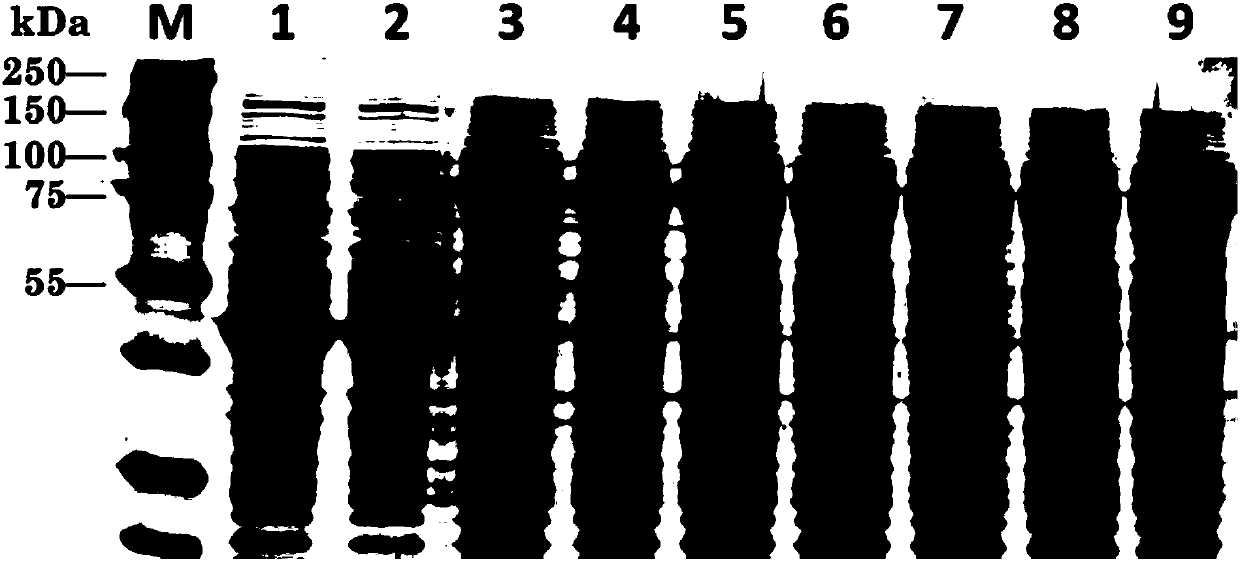

[0059] The bifunctional enzyme recombinant strain was inoculated in LB medium, activated overnight at 37°C, 200rpm, then transferred to Lb medium with an inoculum size of 1%, cultivated at 37°C, 200rpm until the OD600 was about 0.5, and added a final concentration of 0.2 mM IPTG, 16°C, 200rpm induced expression for 24h. After the cultivation was completed, the bacterial cells were collected, washed twice with PBS buffer (pH=7.2), and stored at -80°C until use. Whole-cell SDS-PAGE was used to verify whether the recombinant bifunctional enzyme was successfully expressed, and the results were as follows: figure 2 As shown, where M represents the protein marker, bands 1-9 are FDH single enzyme, LeuDH single enzyme, FDH-DL-LeuDH, FDH-S1-LeuDH, FDH-S2-LeuDH, FDH-S3-LeuDH, FDH-R1 -LeuDH, FDH-R2-LeuDH and FDH-R3-LeuDH, it can be seen that the bifunctional enzymes mediated by the seven connecting peptides were all suc...

Embodiment 3

[0062] Characterization of Bifunctional Enzyme Active Inclusion Body

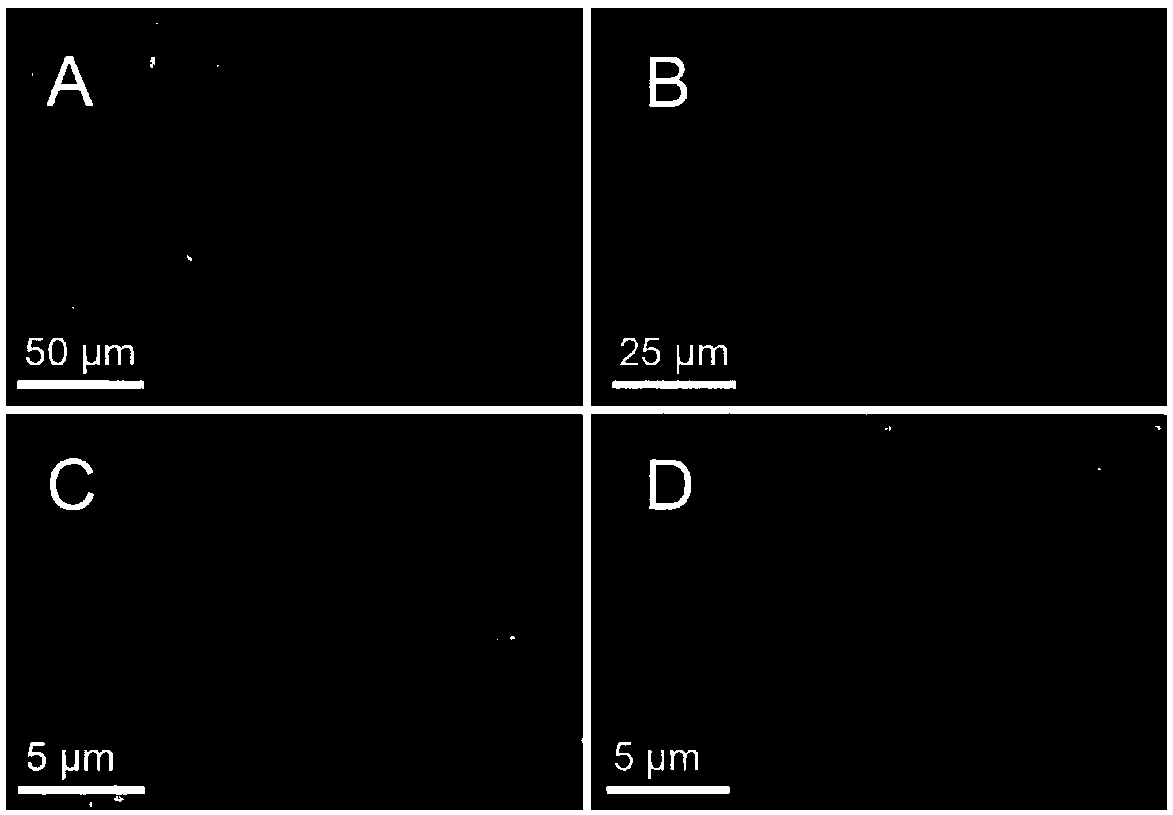

[0063] The morphology of inclusion bodies was directly observed by scanning electron microscopy. The sample preparation method is as follows: 5 μL of the inclusion body sample was dropped on a single crystal silicon wafer, air-dried overnight, and then coated with about 2 nm thick platinum in a JFC-1600 (JEOL, Tokyo, Japan) sputtering apparatus (sputtering condition : 10mA, 30s), and then put the coated sample into a field emission Sigma scanning electron microscope (Carl-Zeiss AG, Germany) for observation. image 3 It is the SEM structure diagram of partial inclusion body, where A is FDH-R1-LeuDH, B is FDH-R2-LeuDH, C is FDH-S1-LeuDH, D is FDH-S2-LeuDH, it can be seen that the rigid linker peptide mediates The inclusion body with bifunctional enzyme activity showed a sheet structure, while the inclusion body with bifunctional enzyme activity mediated by a flexible linker peptide presented an irregular bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com