High-efficiency compound phosphorus removal agent and preparation method thereof

A compound dephosphorization agent, high-efficiency technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., can solve the problems of increasing labor costs and reagent costs, consuming manpower and chemicals, and high operating costs , to achieve the effect of less chemical dosage, low treatment cost and obvious phosphorus removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

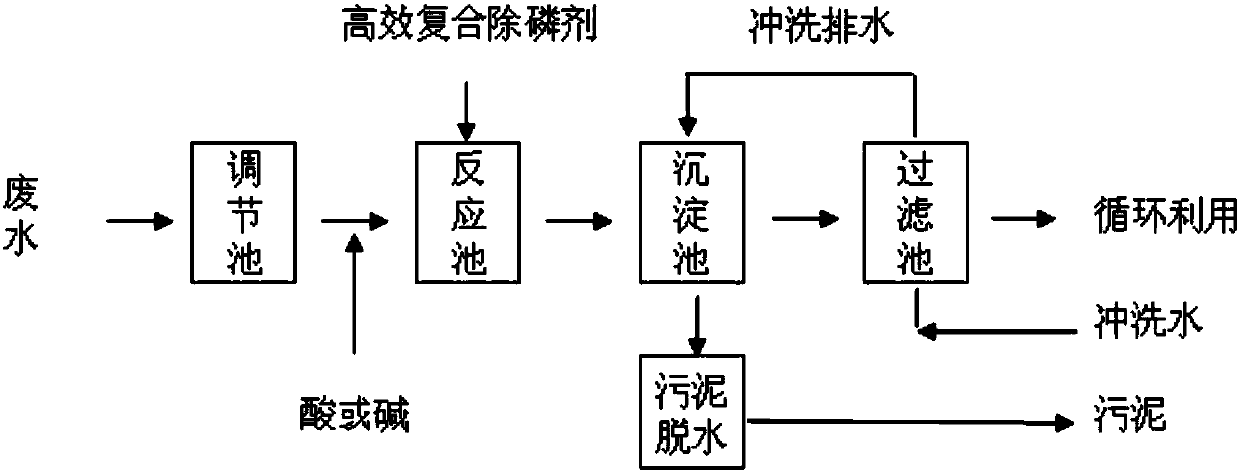

Method used

Image

Examples

Embodiment 1

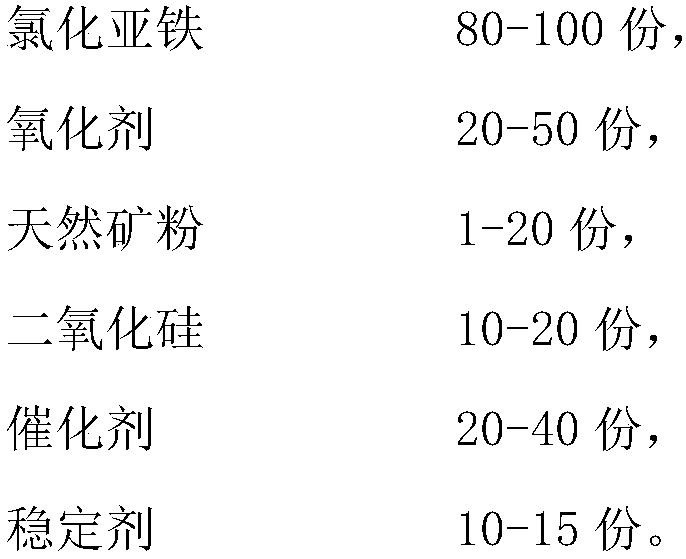

[0027] A high-efficiency composite phosphorus removal agent consists of the following components in parts by mass:

[0028]

[0029] A preparation method of high-efficiency composite phosphorus removal agent, comprising the following steps:

[0030] 1) Put ferrous chloride into the reaction kettle, add hydrochloric acid and hydrogen peroxide in sequence, heat to 85°C and stir for 2 hours;

[0031] 2) Add natural mineral powder, stir evenly, add silicon dioxide, heat to 85°C and stir for 1 hour;

[0032] 3) Continue to add sodium nitrite and react at 85°C for 4 hours to obtain a high-efficiency composite phosphorus removal agent.

Embodiment 2

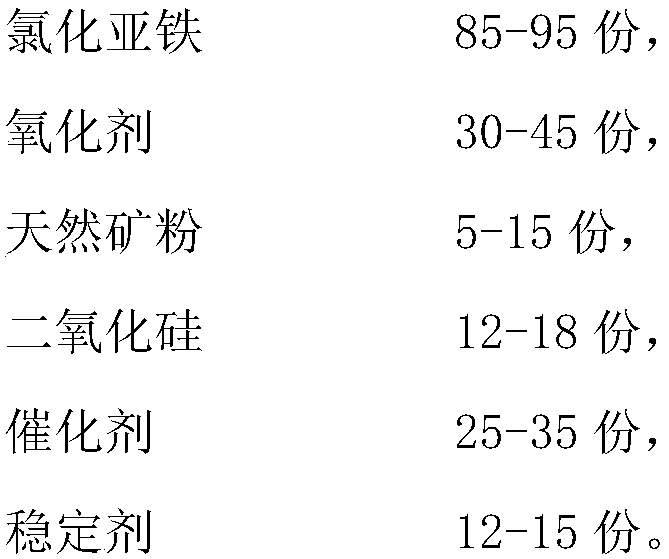

[0034] A high-efficiency composite phosphorus removal agent consists of the following components in parts by mass:

[0035]

[0036] A preparation method of high-efficiency composite phosphorus removal agent, comprising the following steps:

[0037] 1) Put ferrous chloride in the reaction kettle, add hydrochloric acid and hydrogen peroxide in sequence, heat to 85°C and stir for 1.5 hours;

[0038] 2) Then add natural mineral powder, stir evenly, add silicon dioxide, heat to 85°C and stir for 2 hours;

[0039] 3) Continue to add sodium nitrite and react at 90°C for 5 hours to obtain a high-efficiency composite phosphorus removal agent;

[0040] 4) Drying and dehydrating the high-efficiency composite phosphorus removal agent in step 3) at 80° C. to make a solid high-efficiency composite phosphorus removal agent.

Embodiment 3

[0042] A high-efficiency composite phosphorus removal agent consists of the following components in parts by mass:

[0043]

[0044] A preparation method of high-efficiency composite phosphorus removal agent, comprising the following steps:

[0045] 1) Put ferrous chloride in the reaction kettle, add hydrochloric acid and hydrogen peroxide in sequence, heat to 90°C and stir for 2 hours;

[0046] 2) Then add natural mineral powder, stir evenly, add silicon dioxide, heat to 90°C and stir for 2 hours;

[0047] 3) Continue to add sodium nitrite and react at 100°C for 5 hours to obtain a high-efficiency composite phosphorus removal agent;

[0048] 4) Drying and dehydrating the high-efficiency composite phosphorus removal agent in step 3) at 100° C. to make a solid high-efficiency composite phosphorus removal agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com