Silicon-zinc-modified catalyst carrier and preparation method and application thereof

A technology of catalyst carrier and alumina carrier, which is applied in the direction of catalyst carrier, catalyst activation/preparation, chemical instruments and methods, etc., can solve problems such as limiting industrial application, polluting gas, equipment corrosion, etc., and achieve improved operation stability performance, simple operation, and improved hydrogenolysis performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] The present invention will be described in detail below by way of examples.

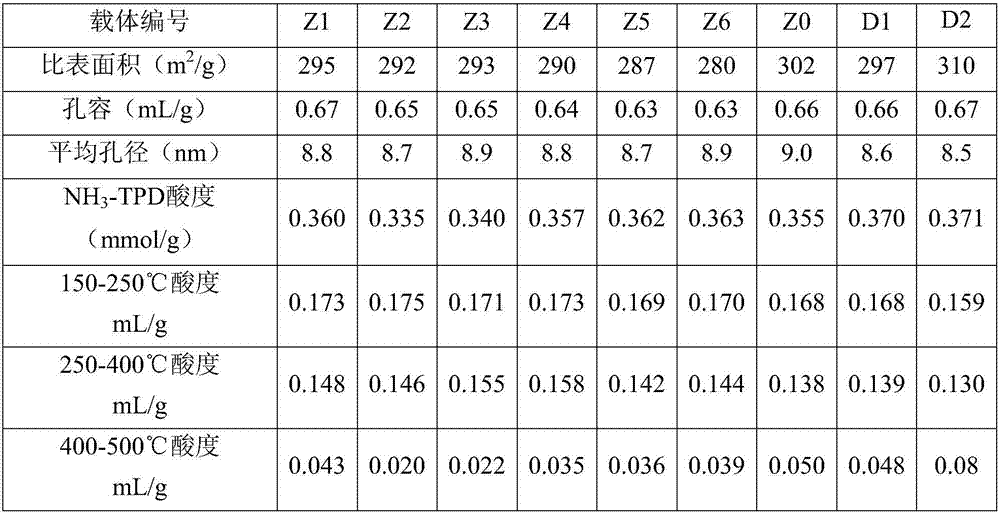

[0044] In the following examples, the specific surface area, pore volume and pore diameter of the sample were measured by the ASAP2405 physical adsorption instrument of American Mike Instrument Company, and the liquid N 2 As an adsorbate, the adsorption temperature was -196°C, and the specific surface area of the sample was calculated using the BET method.

[0045] NH 3 - The TPD measurement was carried out on the automatic catalyst characterization system AutoChem2920 of American Micro Instrument Company. The catalyst was purged with helium gas at 400 ° C for 1 hour, and then the helium atmosphere was cooled to room temperature, and ammonia gas was adsorbed to saturation. After purging until the baseline was stable, the temperature was raised to 140°C for temperature-programmed desorption, the heating rate is 10°C·min -1 , 150-250°C acidity, 250-400°C acidity, 400-500°C acidity through NH...

preparation example 1

[0049] This preparation example is used to illustrate the preparation method of alumina carrier.

[0050] Take 150g of large-pore aluminum hydroxide dry rubber powder, 50g of small-pore aluminum hydroxide dry rubber powder, add 6g of squash powder, mix well, pour into a roller compactor, and dry mix for 5 minutes. Then, 170 g of an aqueous solution of citric acid and nitric acid (containing 6 g of citric acid and 9.23 g of nitric acid at a concentration of 3.2% by weight) were uniformly added thereto. The material was rolled for 20 minutes and extruded with a clover orifice plate with a diameter of 1.7 mm. Dry at 120°C for 4 hours and then bake at 550°C for 5 hours. The calcined alumina support is denoted as Z0. The physical and chemical properties of the alumina carrier Z0 are shown in Table 1.

Embodiment 1

[0052] Weigh 2.0g of zinc nitrate and dissolve it in deionized water with a volume of 30mL to obtain solution A; weigh 4.0g of amino-modified silicone oil and add an appropriate amount of deionized water to dissolve it with a volume of 30mL to obtain solution B; Under the condition of constant stirring, slowly pour solution B into solution A, add appropriate amount of deionized water, the final volume is 85mL, and prepare solution C.

[0053] Weigh 100g of alumina carrier Z0, uniformly immerse the alumina carrier in solution C for 8 hours, dry at 120°C for 3 hours, and calcinate at 450°C for 3 hours to obtain silicon-zinc modified catalyst carrier Z1. The physical and chemical properties of carrier Z1 are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com