Synchronous extracting method of antrodia camphorate total triterpene and polysaccharide

A technology of simultaneous extraction and total polysaccharide, applied in pharmaceutical formulations, medical preparations containing active ingredients, plant raw materials, etc., can solve the problems of high cost, short extraction time, and high extraction temperature, achieve changes in solubility and shorten extraction time. , the effect of improving the extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

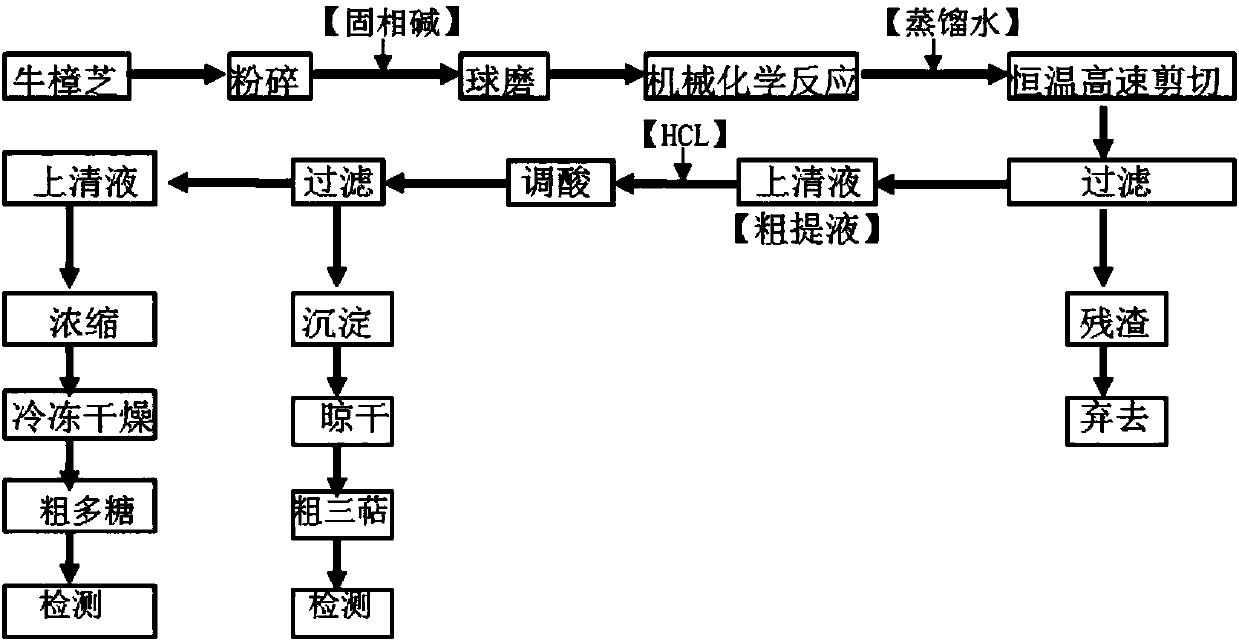

[0066] 1) Raw material pretreatment: cut the fruiting body of Antrodia camphorata into thin slices, dry at 45° C. to constant weight, crush and sieve through a 60-mesh sieve to obtain fruiting body powder of Antrodia camphorata.

[0067] 2) Mechanochemical treatment: Weigh 10 g of Antrodia camphorata fruiting body powder and 1 g of hydrotalcite, and put them into a Retsch PM-200 planetary ball mill for ball milling. The filling rate of the ball mill is 30%. Mill at 300 rpm for 10 minutes.

[0068] 3) Extraction of triterpenes and polysaccharides by constant temperature and high speed shearing: Take the powder of Antrodia camphorata after ball milling in step 2), add 200 mL of distilled water, react at 10,000 rpm and 50°C for 5 minutes, centrifuge the reaction solution at 4,700 rpm for 10 minutes, and the supernatant is the crude oil of Antrodia camphorata. Extraction.

[0069] 4) Separation and purification of total triterpenoids and polysaccharides of Antrodia antrodia: adjus...

Embodiment 2

[0071] 1) Raw material pretreatment: cut the fruiting body of Antrodia camphorata into thin slices, dry at 45° C. to constant weight, crush and sieve through a 60-mesh sieve to obtain fruiting body powder of Antrodia camphorata.

[0072]2) Mechanochemical treatment: take by weighing 10g Antrodia camphorata fruiting body powder and 1g silica gel (grinding aid non-solid phase base) and add to Retsch PM-200 planetary ball mill ball milling tank, ball milling tank filling rate is 30%, with 300rpm, ball milling 10min.

[0073] 3) Constant temperature and high-speed shear extraction of triterpenoids and polysaccharides: Take the ball-milled Antrodia camphorata powder in step 2), add 200 mL of distilled water, react at 10,000 rpm and 50°C for 5 minutes, and centrifuge the reaction solution at 4,700 rpm for 10 minutes to obtain the crude extract of Antrodia camphorata.

[0074] 4) Separation and purification of total triterpenoids and polysaccharides of Antrodia antrodia: adjust the p...

Embodiment 3

[0076] 1) Raw material pretreatment: cut the fruiting body of Antrodia camphorata into thin slices, dry at 45° C. to constant weight, crush and sieve through a 60-mesh sieve to obtain fruiting body powder of Antrodia camphorata.

[0077] 2) Mechanochemical treatment: Weigh 10g of Antrodia camphorata fruiting body powder and 1.0g of hydrotalcite, put them into the ball milling jar of Retsch PM-200 planetary ball mill, and mill with the filling rate of the ball milling jar at 30%, and mill at 100rpm for 10min.

[0078] 3) Constant temperature and high-speed shear extraction of triterpenes and polysaccharides: Take 10 g of Antrodia camphorata powder after ball milling, add 200 mL of distilled water, react at 10,000 rpm and 50°C for 10 minutes, and centrifuge the reaction solution at 4,700 rpm for 10 minutes to obtain a crude extract of Antrodia camphorata.

[0079] 4) Separation and purification of total triterpenoids and polysaccharides of Antrodia antrodia: adjust the pH of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com