Preparation method of nano-chromium oxyfluoride catalyst with high specific surface area

A technology of chromium oxyfluoride catalyst and high specific surface area, which is applied in the direction of catalyst activation/preparation, nanotechnology for materials and surface science, chemical instruments and methods, etc., and can solve the problem of harsh reaction conditions, complex process, large particle size, etc. problems, to achieve the effect of mild preparation conditions, easy access to raw materials, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

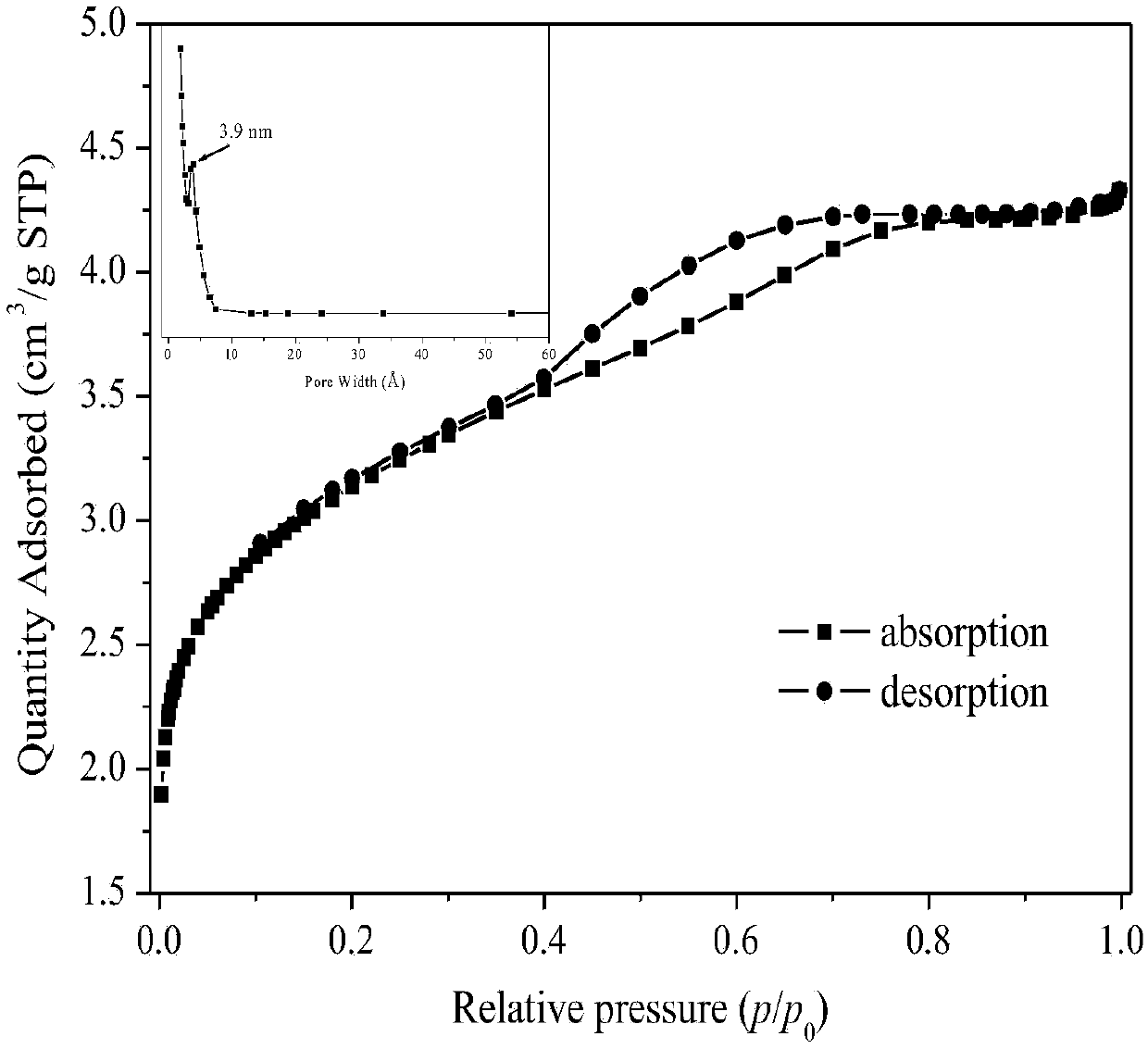

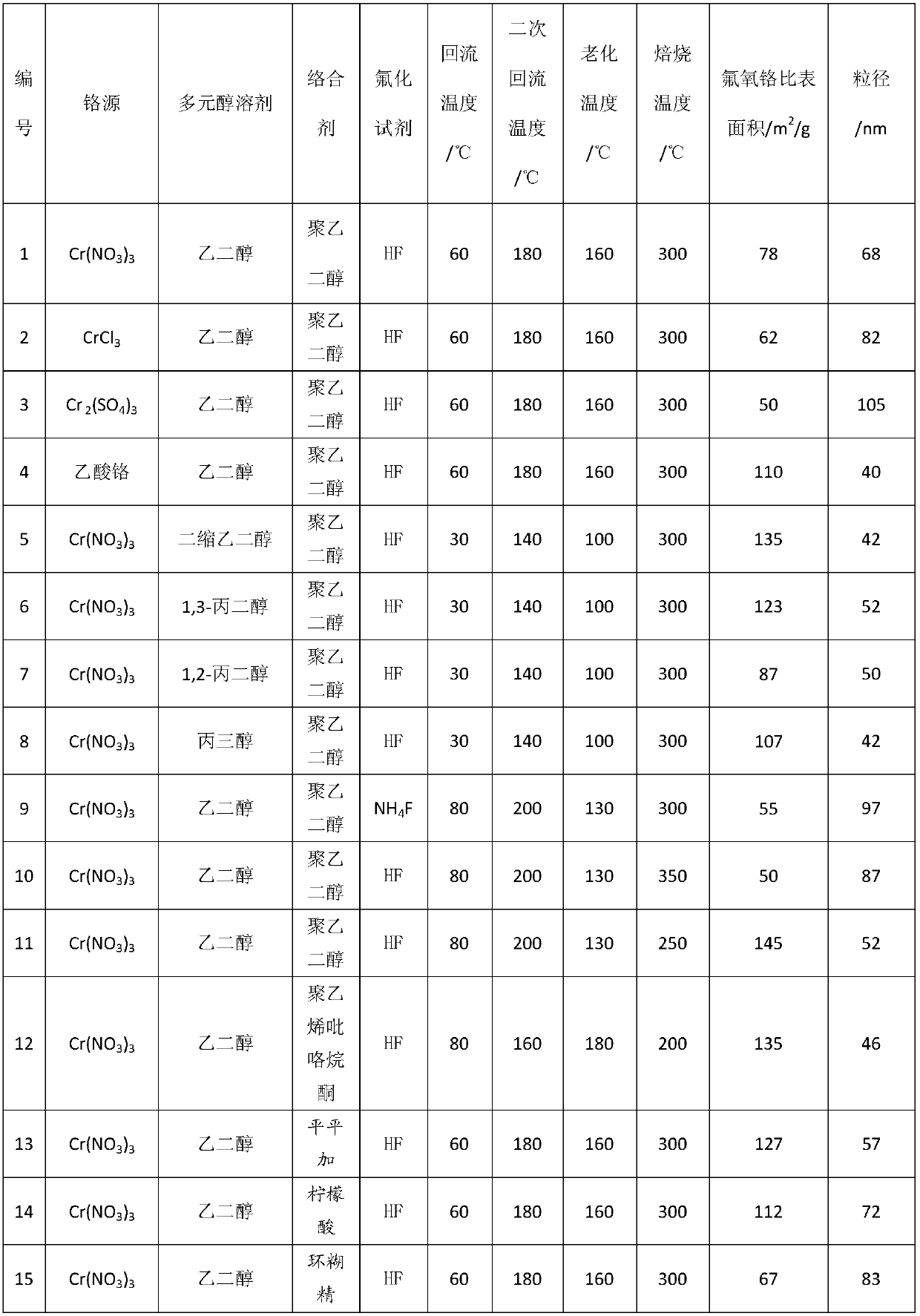

[0022] Embodiment 1: Preparation of high specific surface nano-chromium oxyfluoride catalyst

[0023] Dissolve 1.0M chromium source in 50mL polyol solvent, reflux at 30-80°C for 6 hours, then add the fluorinated reagent dropwise to the above solution with stirring, the dropping time is 30min, and then Reflux and stir at 140°C-200°C for 6 hours to obtain a suspension; then statically age at 100-160°C for more than 24 hours, then wash and filter to obtain a solid; finally roast at 200-350°C for more than 4 hours in an air atmosphere to prepare A high surface nanocrystalline chromium oxyfluoride catalyst material was obtained. The texture properties of chromium oxyfluoride prepared under different chromium sources, polyol solvents, complexing agents, fluorinating reagents, and calcination temperatures are shown in Table 1.

[0024] The physicochemical property results of the high specific surface nano-chromium oxyfluoride catalyst of Table 1 Example 1

[0025]

[0026]

Embodiment 2

[0027] Embodiment 2: Preparation of high specific surface nano-chromium oxyfluoride catalyst

[0028] Dissolve 1.0M chromium nitrate and polyethylene glycol in 50mL of ethylene glycol, reflux at 60°C for 6h, then add HF aqueous solution (40wt.%) dropwise to the above solution with stirring, and the dropping time is After the dropwise addition, reflux and stir at 160°C for 6h to obtain a suspension; then stand and age at 160°C for more than 24h, then wash and filter to obtain a solid; finally roast at 300°C for more than 4h to obtain a high Specific surface nanocrystalline chromium oxyfluoride. The textures of chromium oxyfluoride obtained with different amounts of polyethylene glycol are shown in Table 2.

[0029] Table 2 The results of the physical and chemical properties of the high specific surface nano-chromium oxyfluoride catalyst of Example 2

[0030] Numbering

Embodiment 3

[0031] Embodiment 3: Preparation of high specific surface nano-chromium oxyfluoride catalyst

[0032] Dissolve 1.0M chromium nitrate and polyethylene glycol (Cr / complexing agent mass ratio: 1:3) in 50 mL of ethylene glycol, reflux at 60°C for 6 hours, then add HF aqueous solution dropwise to In the above solution, the dropwise addition time is 30min. After the dropwise addition, reflux and stir at 160°C for 6h to obtain a suspension; then statically age at 160°C for more than 24h, then wash and filter to obtain a solid; finally at 300°C Calcined under the lower pressure for more than 4 hours, the high specific surface nanocrystalline chromium oxyfluoride was prepared. The textures of chromium oxyfluoride prepared with different HF concentrations are shown in Table 3.

[0033] The physicochemical property results of the high specific surface nano-chromium oxyfluoride catalyst of table 3 embodiment 3

[0034]

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com