Production method for fiber-supported catalyst prepared by using microfluidic one-step method and application of fiber-supported catalyst to paraaminophenol

A production method and microfluidic technology, applied in catalytic reactions, chemical instruments and methods, catalyst activation/preparation, etc., can solve problems such as short mixing time, and achieve the effect of ensuring catalytic activity, large volume, and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

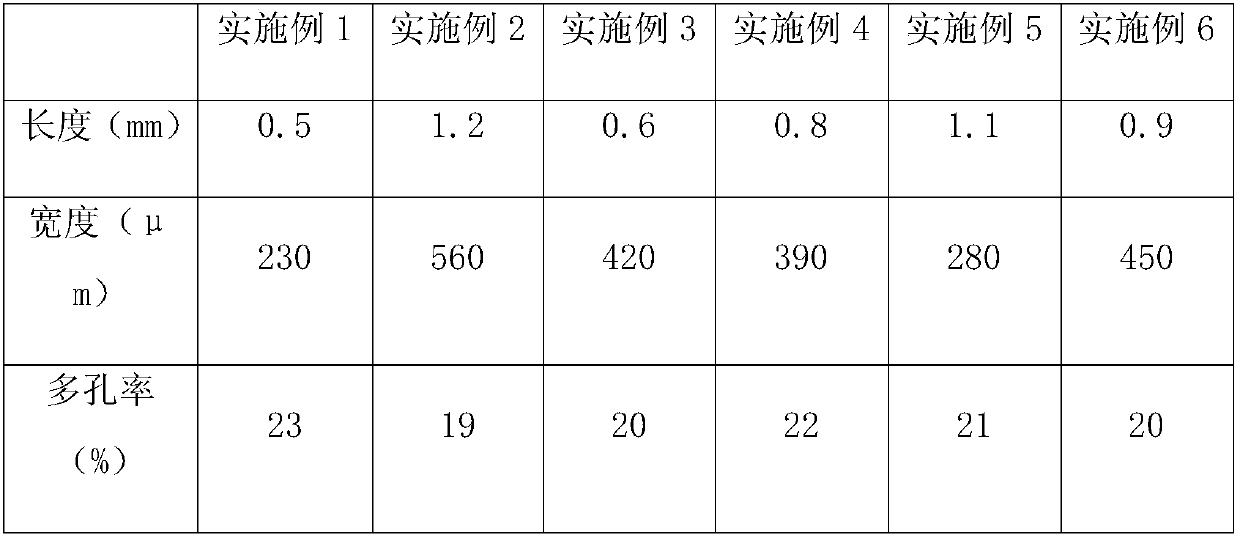

Embodiment 1

[0028] (1) Slowly add the three-dimensional chitosan sol with a particle size of 40-80nm into the graphene oxide solution of 3 mg / L, stir ultrasonically, evaporate the solvent and concentrate to obtain a carrier sol with a solid content of 50%, wherein the shell in the carrier sol The mass ratio of polysaccharide to graphene oxide is 50:3.

[0029] (2) the SO4 of the nickel nitrate loading of 1wt% 2- / MXOY solid superacid powder and bronsted acidic ionic liquid are mixed uniformly to obtain a loaded suspension with a solid content of 10%.

[0030] (3) Using the coaxial microfluidic channel network as a device, the carrier solution is loaded into the innermost syringe, the load solution is loaded into the outermost syringe, and the hydrazine hydrate reducing agent is added to the middle syringe, respectively, using a numerically controlled syringe pump. Control the flow rate of the carrier solution to be 0.1ml / min, the flow rate of the outermost injector to be 0.4ml / min, and t...

Embodiment 2

[0032] (1) Slowly add the three-dimensional chitosan sol with a particle size of 40-80nm into the graphene oxide solution of 5 mg / L, stir ultrasonically, evaporate the solvent and concentrate to obtain a carrier sol with a solid content of 70%, wherein the shell in the carrier sol The mass ratio of polysaccharide to graphene oxide is 80:10.

[0033] (2) the SO4 of the nickel nitrate loading of 2wt% 2- / MXOY solid superacid powder and bronsted acidic ionic liquid are mixed uniformly to obtain a loaded suspension with a solid content of 20%.

[0034](3) Using the coaxial microfluidic channel network as a device, the carrier solution is loaded into the innermost syringe, the load solution is loaded into the outermost syringe, and the hydrazine hydrate reducing agent is added to the middle syringe, and the injection pumps are used to separate Control the flow rate of the carrier solution to be 0.2ml / min, the flow rate of the outermost injector to be 0.5ml / min, and the flow rate o...

Embodiment 3

[0036] (1) Slowly add the three-dimensional chitosan sol with a particle size of 40-80nm into the graphene oxide solution of 4 mg / L, stir ultrasonically, evaporate the solvent and concentrate to obtain a carrier sol with a solid content of 55%, wherein the shell in the carrier sol The mass ratio of polysaccharide to graphene oxide is 60:5.

[0037] (2) the SO4 of the nickel nitrate load of 1.5wt% 2- / MXOY solid superacid powder and bronsted acidic ionic liquid were mixed evenly to obtain a loaded suspension with a solid content of 13%.

[0038] (3) Using the coaxial microfluidic channel network as a device, the carrier solution is loaded into the innermost syringe, the load solution is loaded into the outermost syringe, and the hydrazine hydrate reducing agent is added to the middle syringe, and the injection pumps are used to separate Control the flow rate of the carrier solution to be 0.15ml / min, the flow rate of the outermost injector to be 0.45ml / min, and the flow rate of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com